TEST ARTICLES

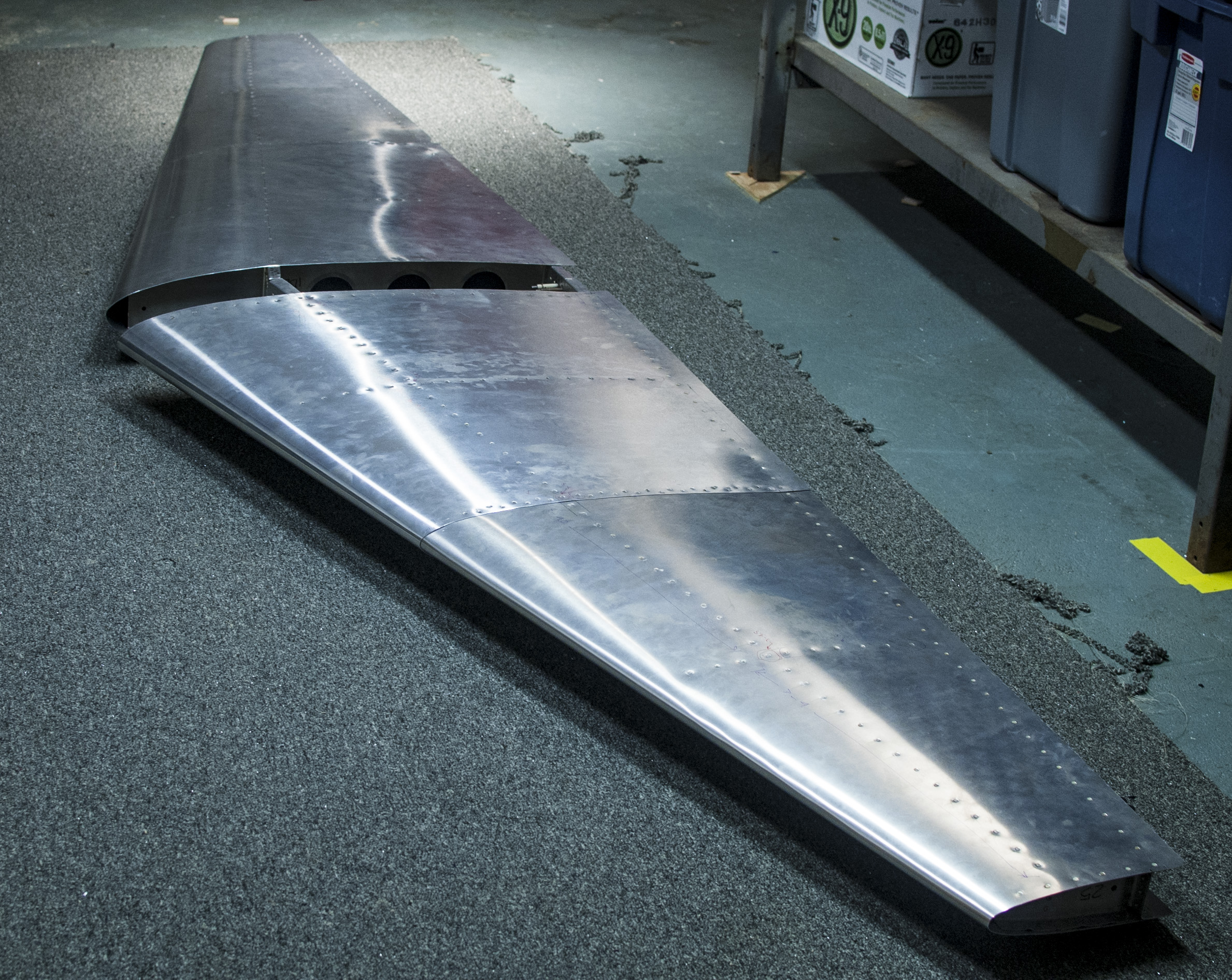

Wing Test Article

The wing test article for the LiteFighter passed with flying colors. We decided to build a full scale, fully identical right wing to validate our wing spar and wing loading calculations. While we knew the calculations were conservative, we had no idea by how much. Actually building a third wing with the intention to destroy in the name of science was not only a great learning experience, but validated the engineering efforts we had iterated over several years (yes years, the main spar has changed cross section design probably a dozen times since the project began).

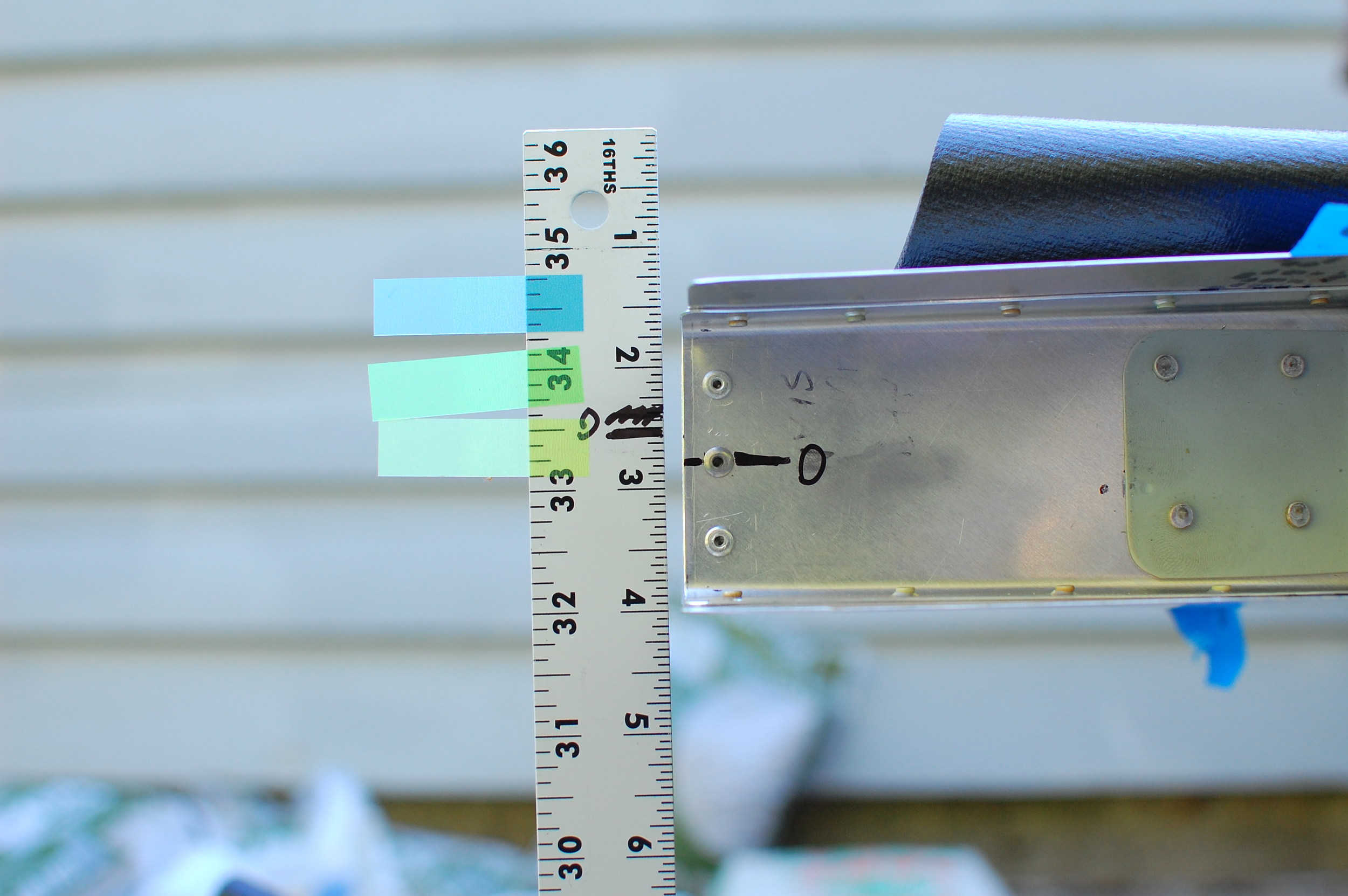

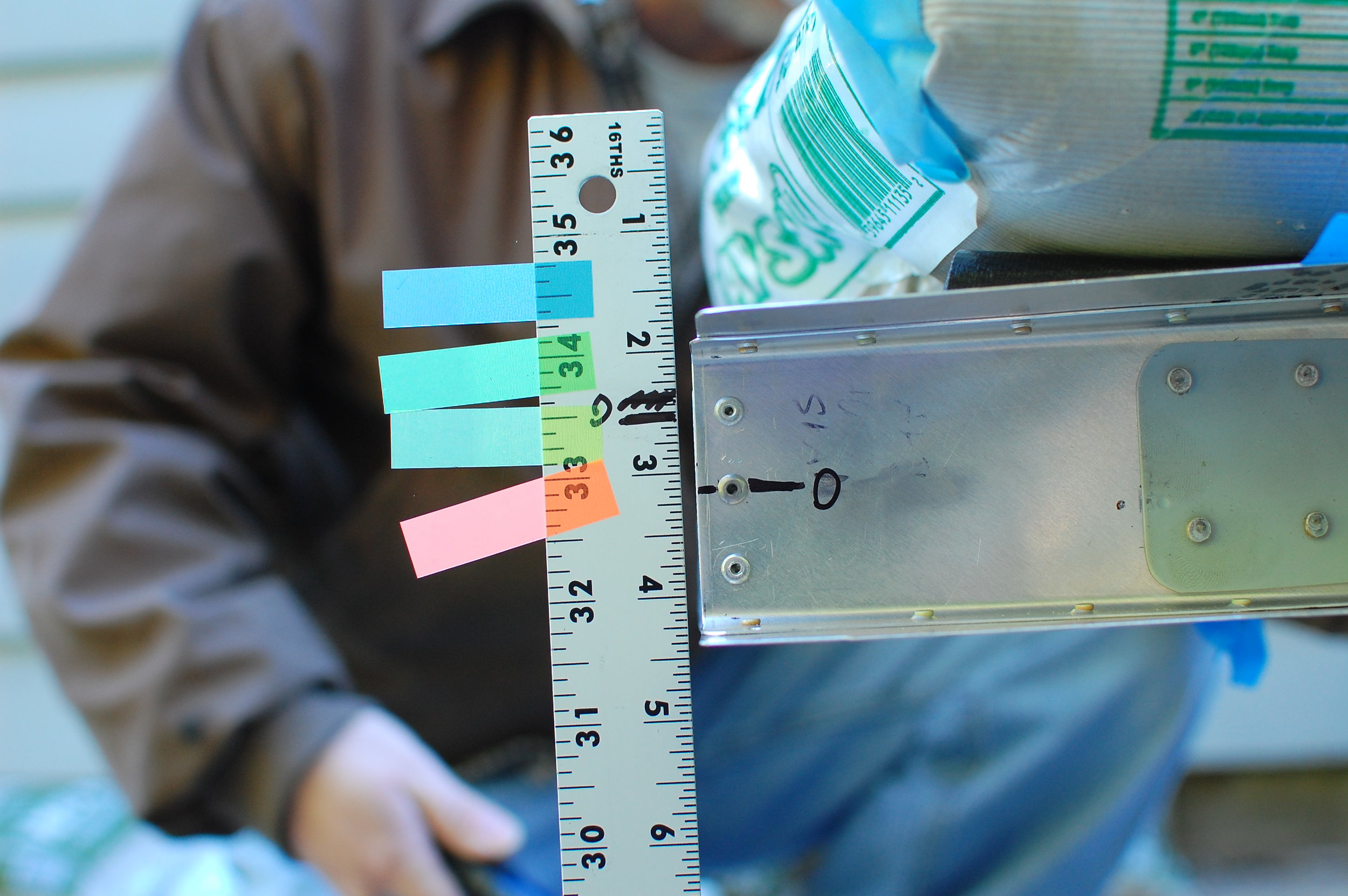

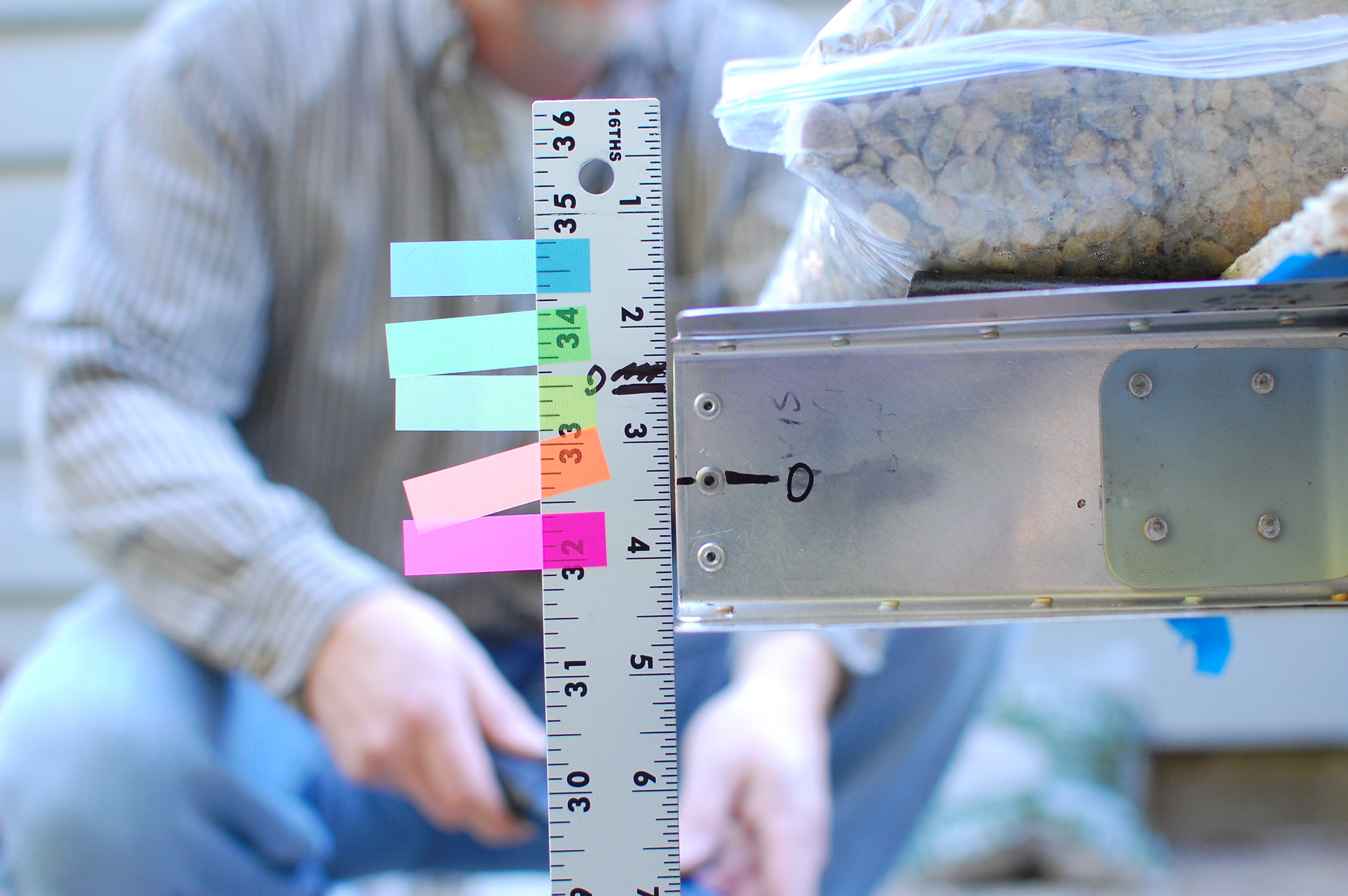

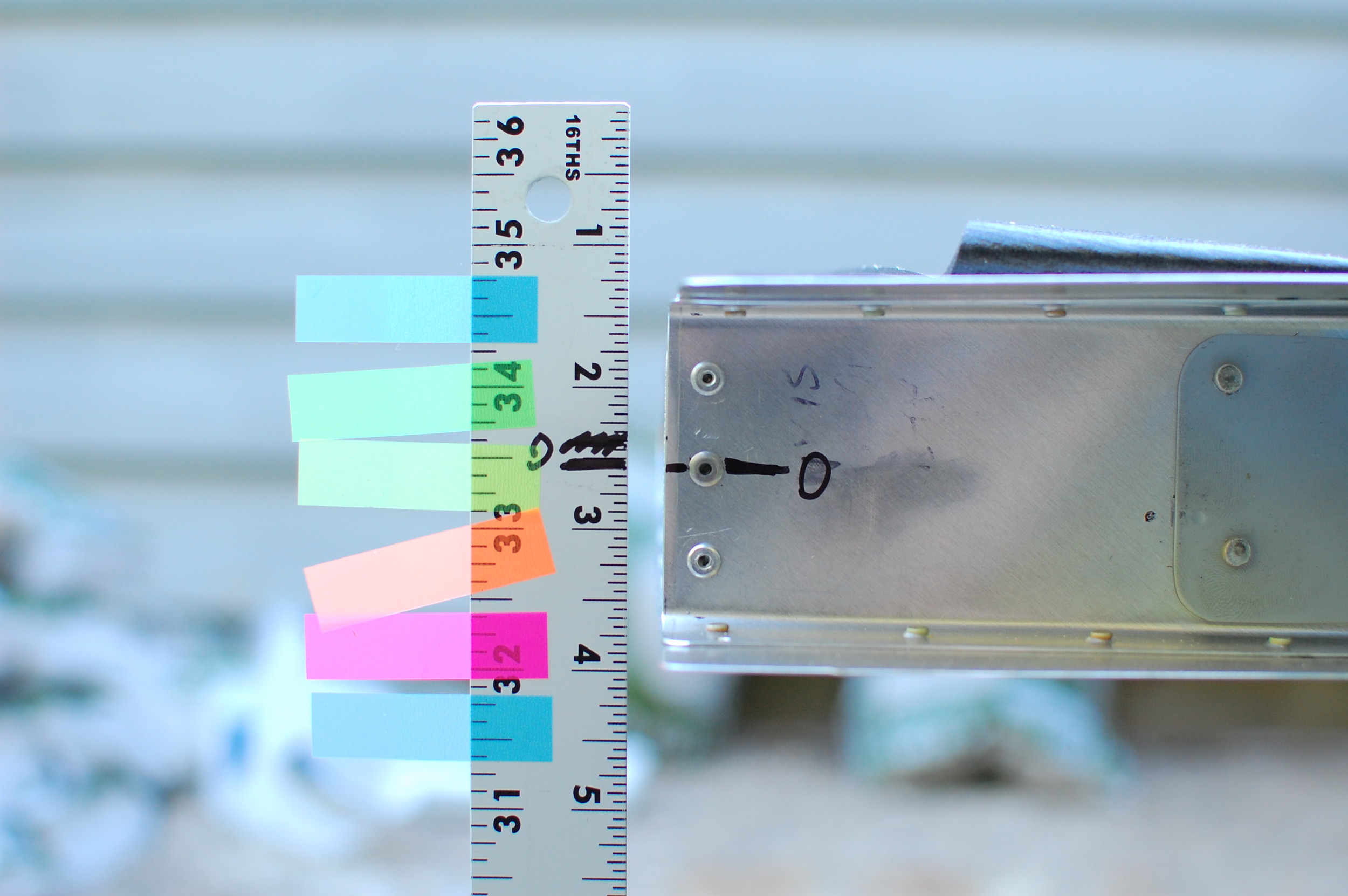

We decided to do this test low tech: 40lb +/-1.5lbs bags of gravel (which later got ‘reused’ into a walkway) loaded on the wing in as close to an elliptical distribution as we could get. The test article was loaded upside down in two configurations, one at an angle to represent maximum load, and one horizontal to test ultimate strength. Deflection was measured after loading to various conditions at one of five datums. There was no plastic deformation noted in two cycles of testing to the maximum design load of the outer wing (1235 lbs). Furthermore, there was no sign of deformation or wear on the main spar pins as well. While deflection began to accelerate and then plastically deform the outer wing as we tested the calculated ultimate strength, we were never actually able to make the wing yield: we ran out of gravel bags first (below)!

The test was an unqualified success! At condition 2-7 wing held 568% of the max gross weight without any signs of failure, exceeded the design goal of +4.4g’s. Deflection at this condition was 7.2”at datum E. Testing halted after this due to exhausting our supply of gravel bags. Overall permanent deformation after the maximum load test (test 1) was 0.44” at datum D. Deformation for ultimate test was measured at 1.38” but is considered inconclusive as the fixture shifted under load.

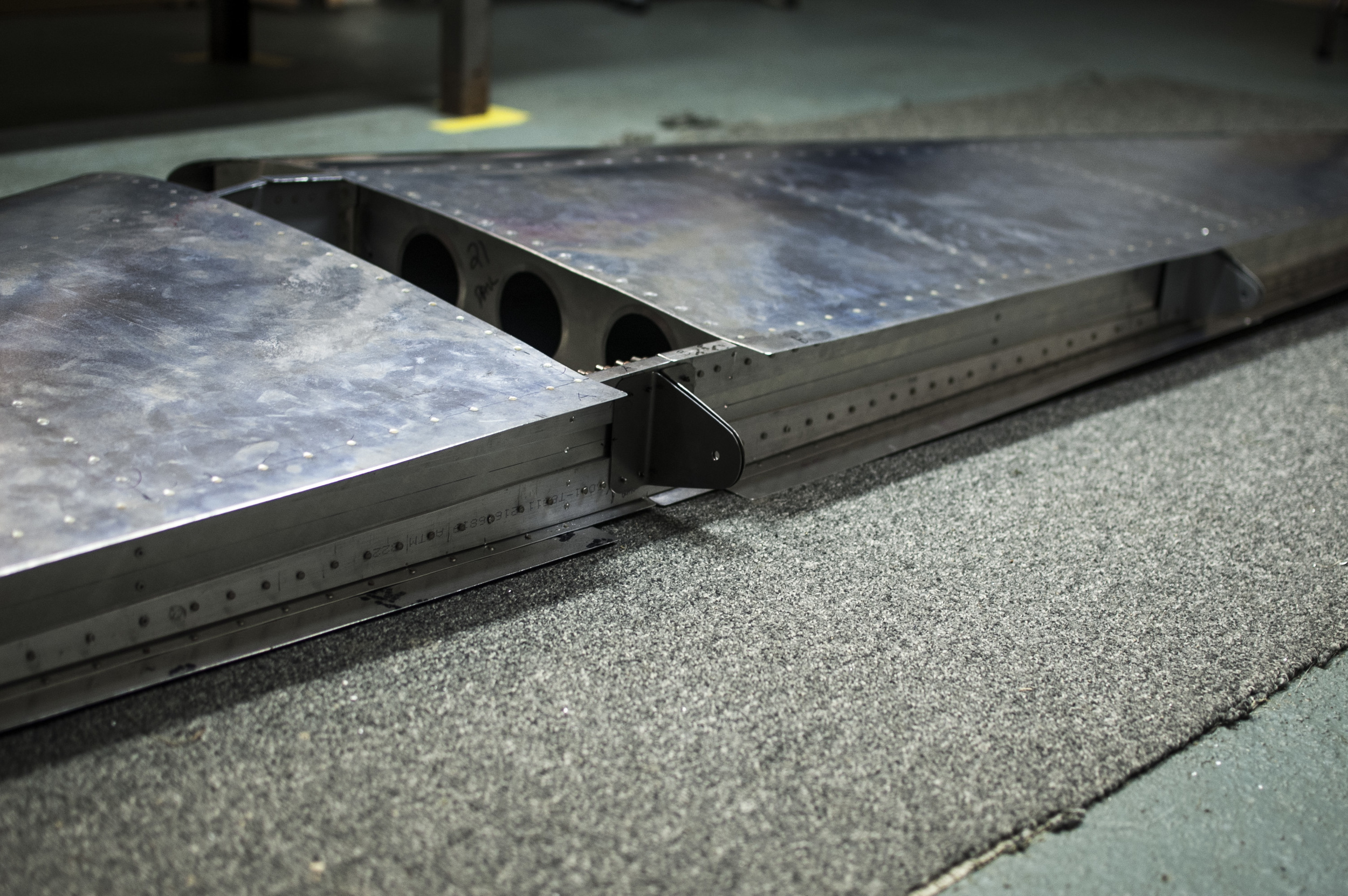

Horizontal Test Article

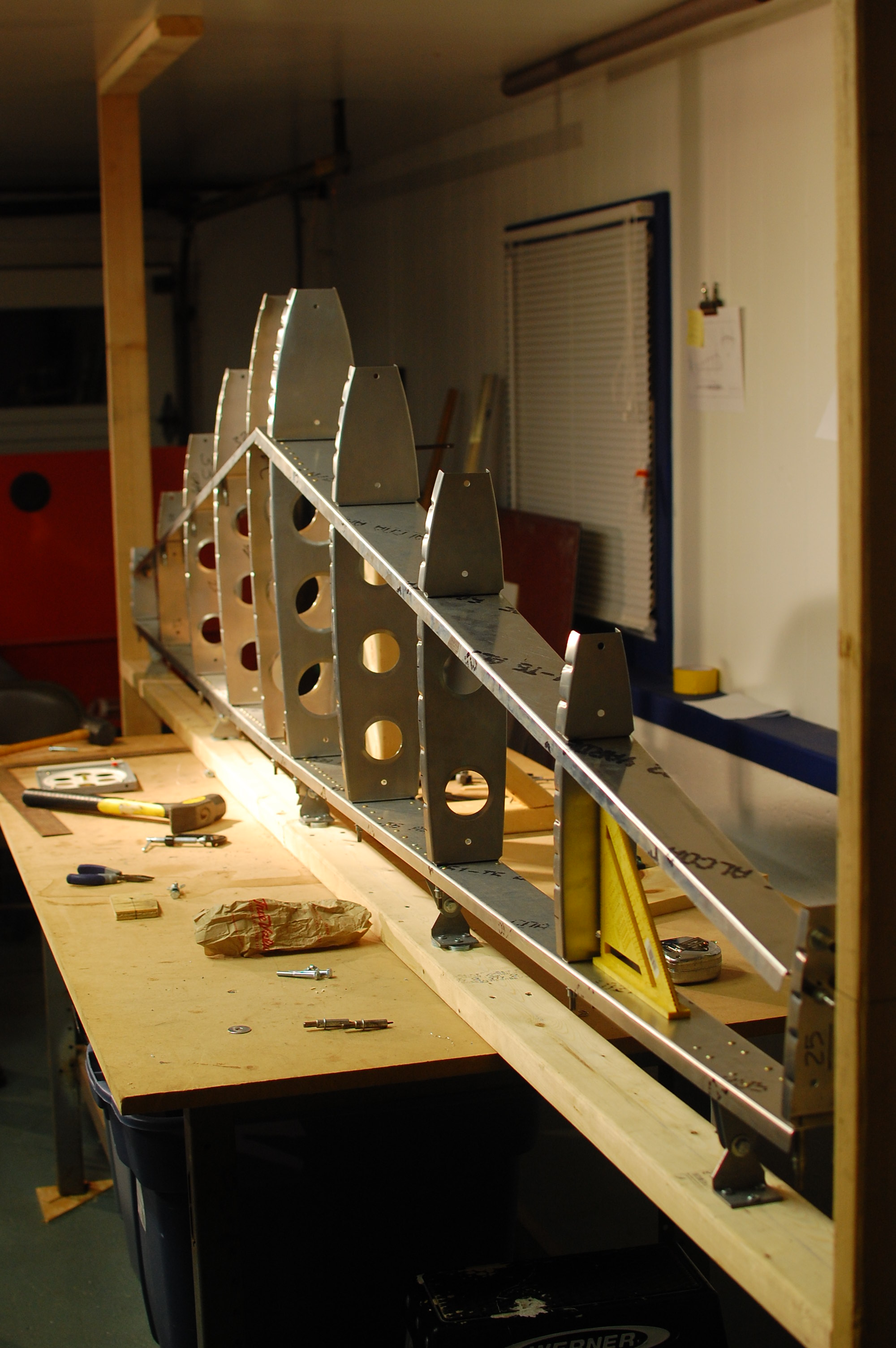

The first physical parts built to plans from our Hellcat design was the Horizontal Stabilizer Test Article. This choice was due to a number of factors: it wasn't too large or complex, the design was already done to a level of confidence, the loading wouldn't require too much weight, and it would help prove our abilities to design and build a simple airfoil before moving to the main wings. Unlike the vertical, it could be mounted in the middle and loaded symmetrically so the test fixture was straightforward.

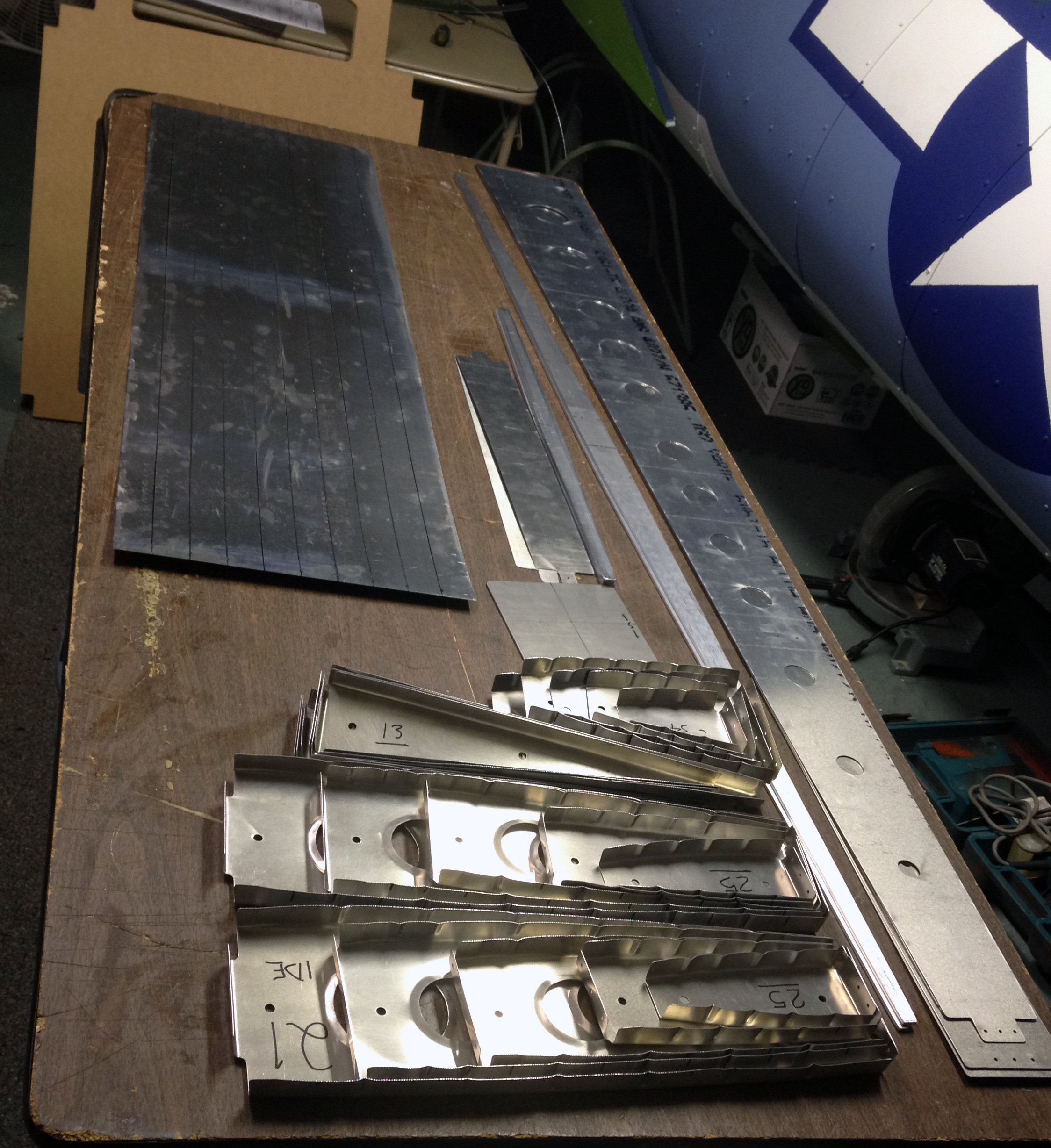

The aluminum parts were sourced and cut by a local metal company with a waterjet. A local remodeling shop produced forming blocks on their CNC router. Our ribs were formed with great success, however our first spars were bent inadequately on a large 8' brake, requiring us to hand-form new spars after multiple vendors refused to quote the job.

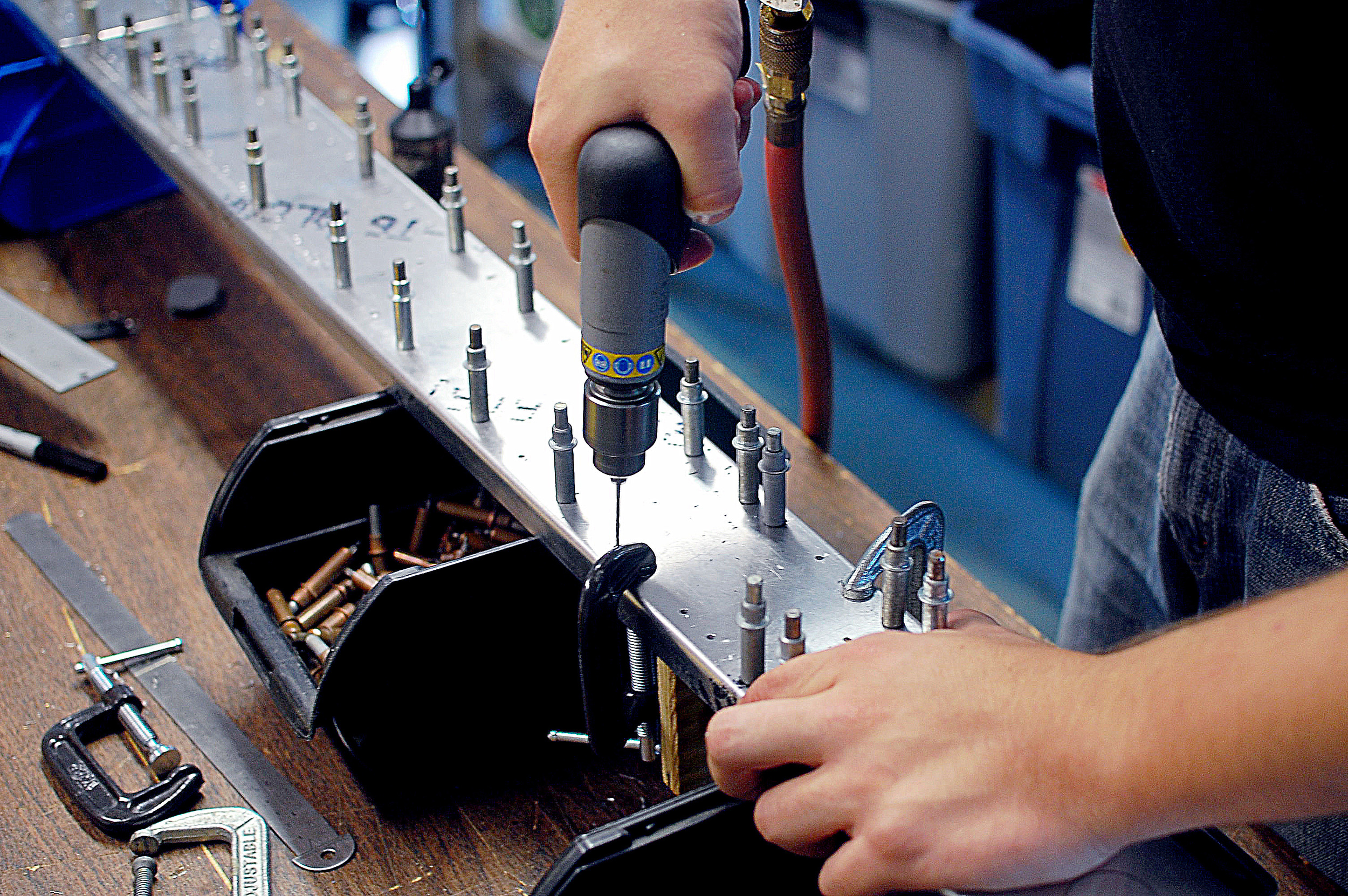

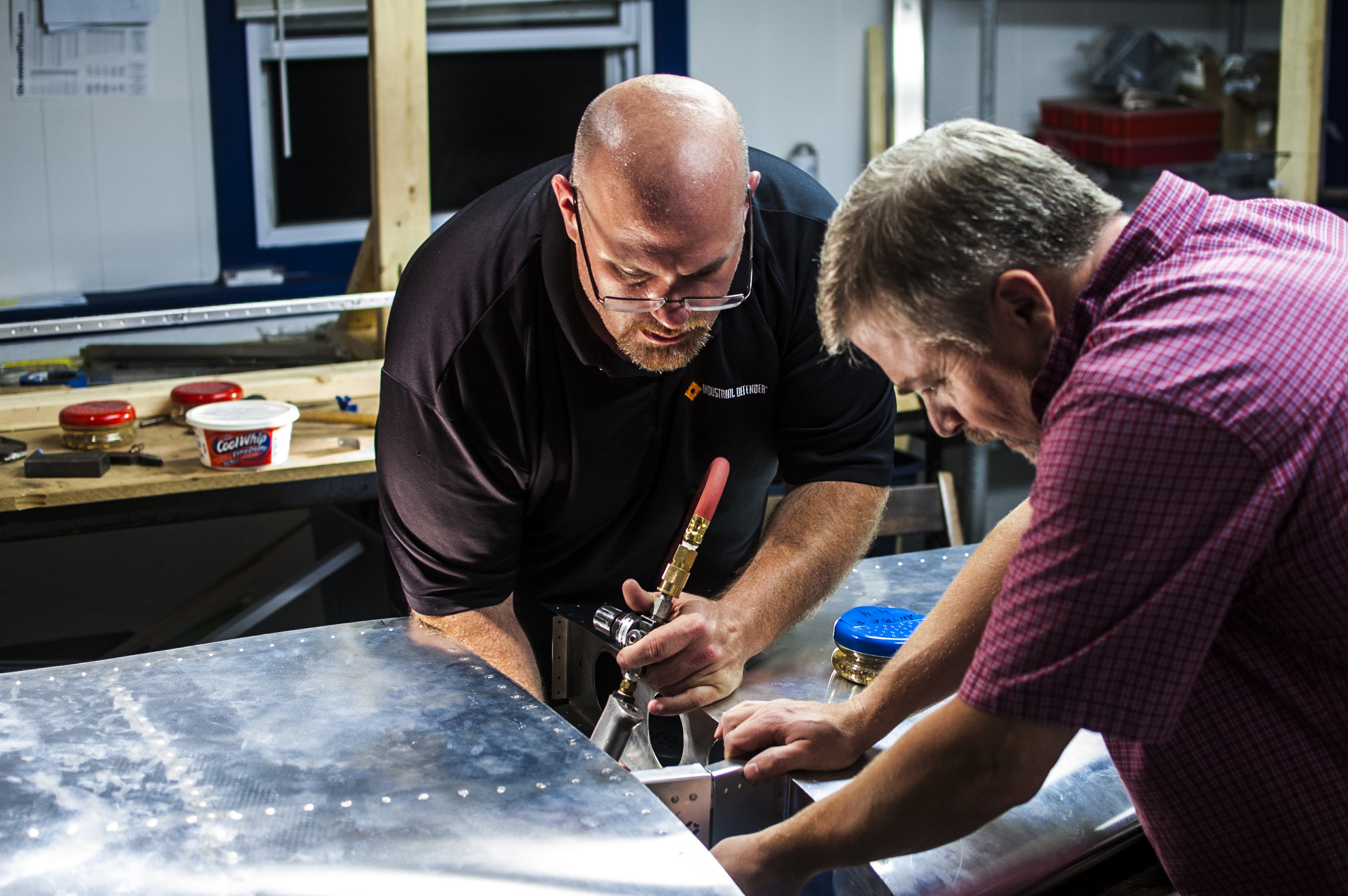

The resulting parts were assembled and riveted with help from the whole team over the course of a few weeks as those with skills passed know-how to those who had never done it before. The hope was that the parts would be less-than-perfect, within a margin, so that the test article wouldn't represent a best-case scenario and would show what happens when newcomers try to put it together.

The test stand was welded together, and the finished horizontal bolted to it.

After loading from 2-6 G simulations, it was taken to 8, 9, and beyond. The structure returned to the original line.