Back From AirVenture 2016

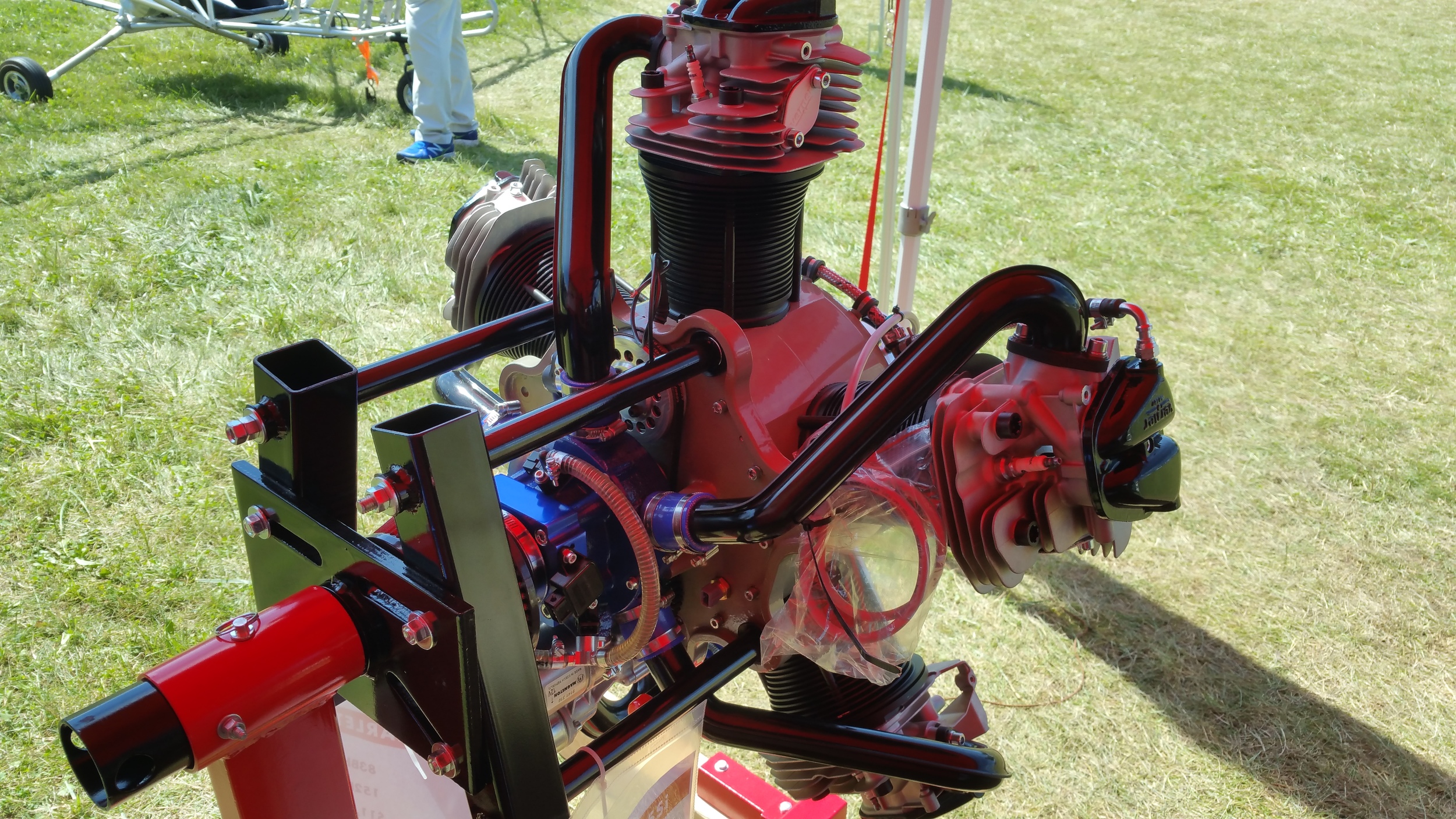

Well, we are home in one piece. Without a lot of time to prepare, we packed up our Scarlett 5Si and took a trip out to Oshkosh, WI for EAA AirVenture. Those of you who saw us there, thanks for stopping in and saying hi! For those who missed us, we don't blame you. Situated in the Ultralights section, in the Performance Propellers USA booth with Frank Johnson and his Verner 3VW, you had to just be there and see our engines shining in the sun to know we were on the scene. But yes, Performance Propellers and Scalebirds both brought our motors to promote the word that Verner radial engines are finally here in the USA! Tons of good response, tons of questions, and while I personally have been a vendor at events before, none are like AirVenture. It was a great experience and gave us great exposure to what the rest of the community is thinking.

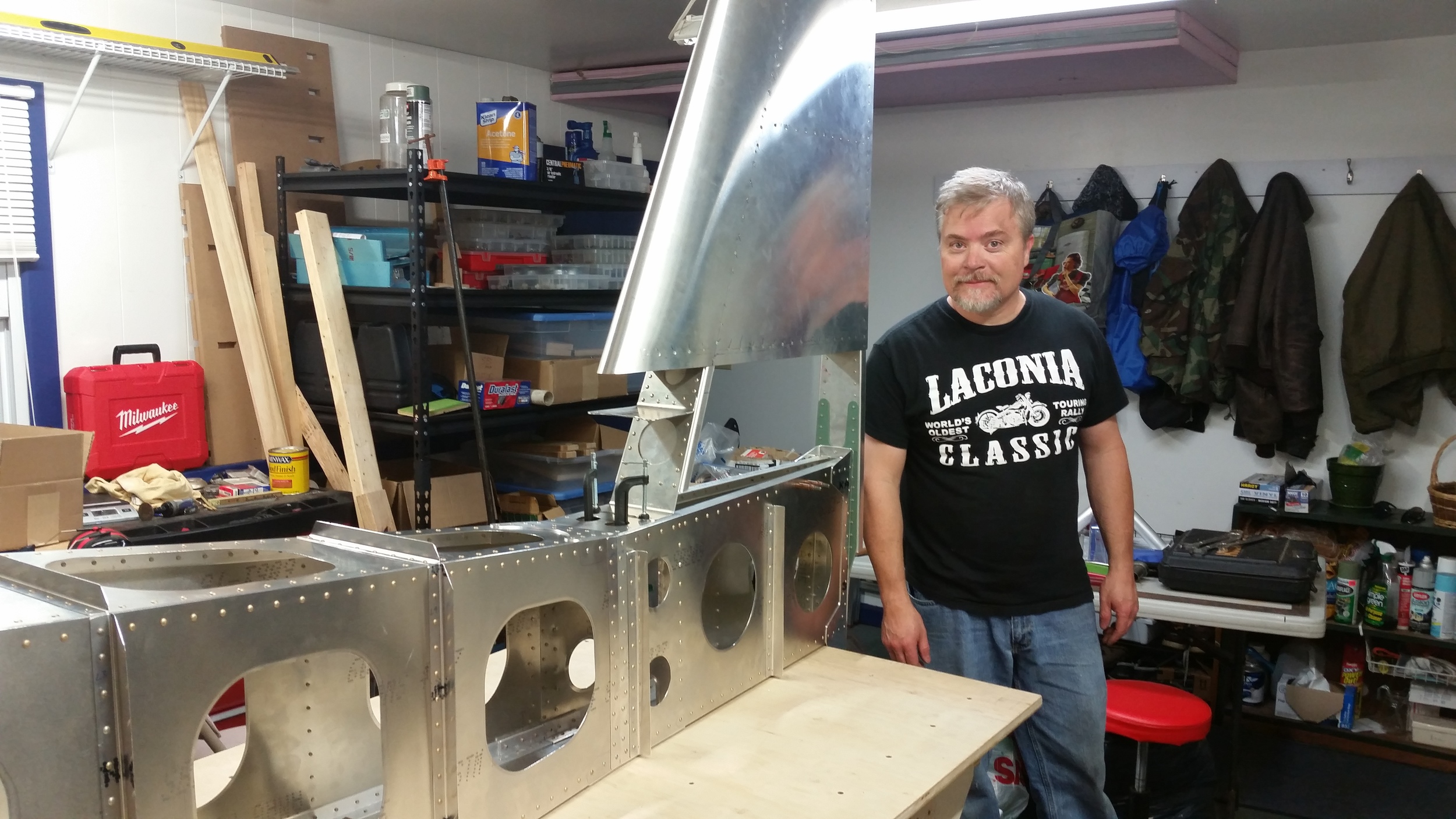

Here's some pics of the Performance Propellers booth:

Again, thanks to Frank Johnson for sharing space with us and putting up with our little project. If anyone is looking for fine, hand-made wooden propellers custom to their exact needs, Frank can do that for ya', check out his site at:

http://www.performancepropellersusa.com/

Anyway, now that we're settled in and things are put away, I'm finally back and able to start working on updating our site, which so far has only a bare mention of the Verner radials and almost nothing on the LiteFighters. That will be changing soon. Real soon. Exepect updates to go over it but in general we'll have more thorough information on the Verner engines on offer, FAQ's, technical documents for download, plus pricing and order forms for the engines if you decide round is for you.

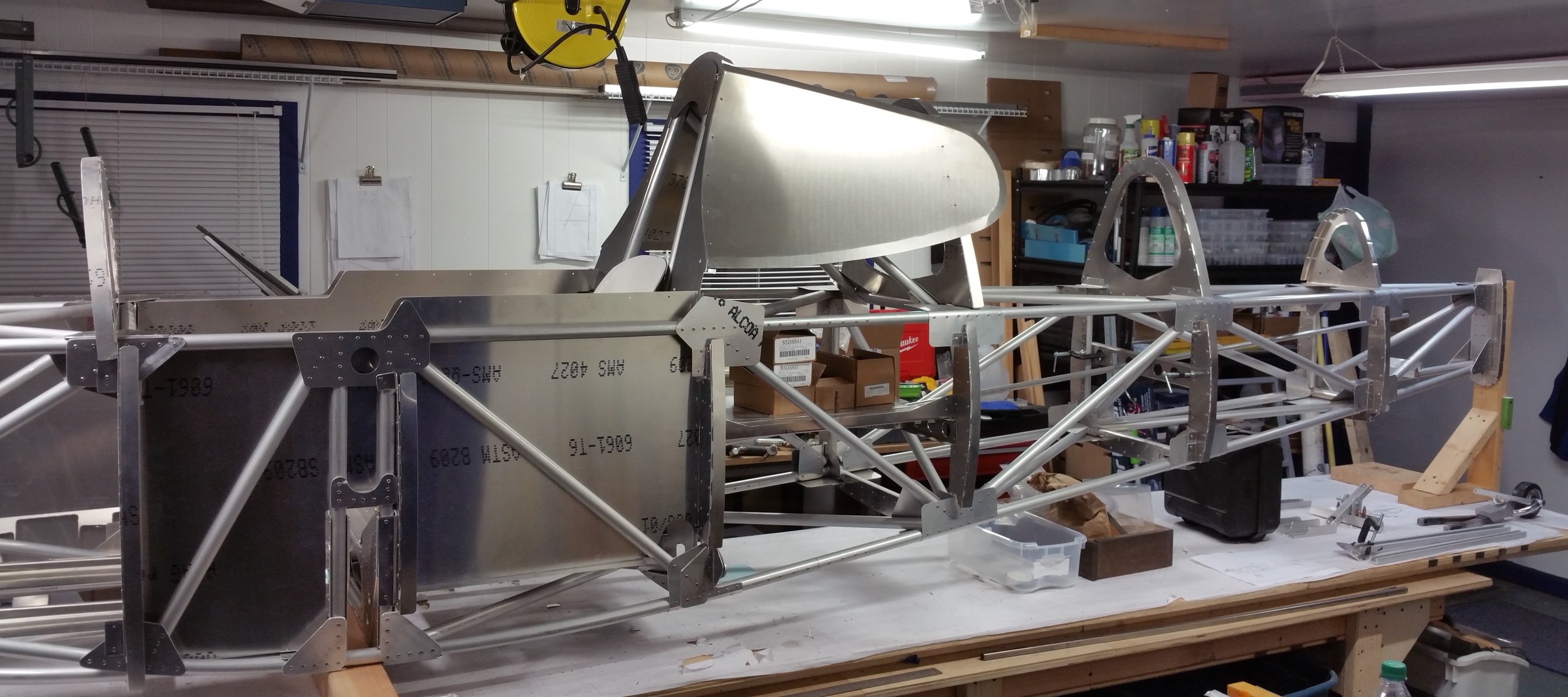

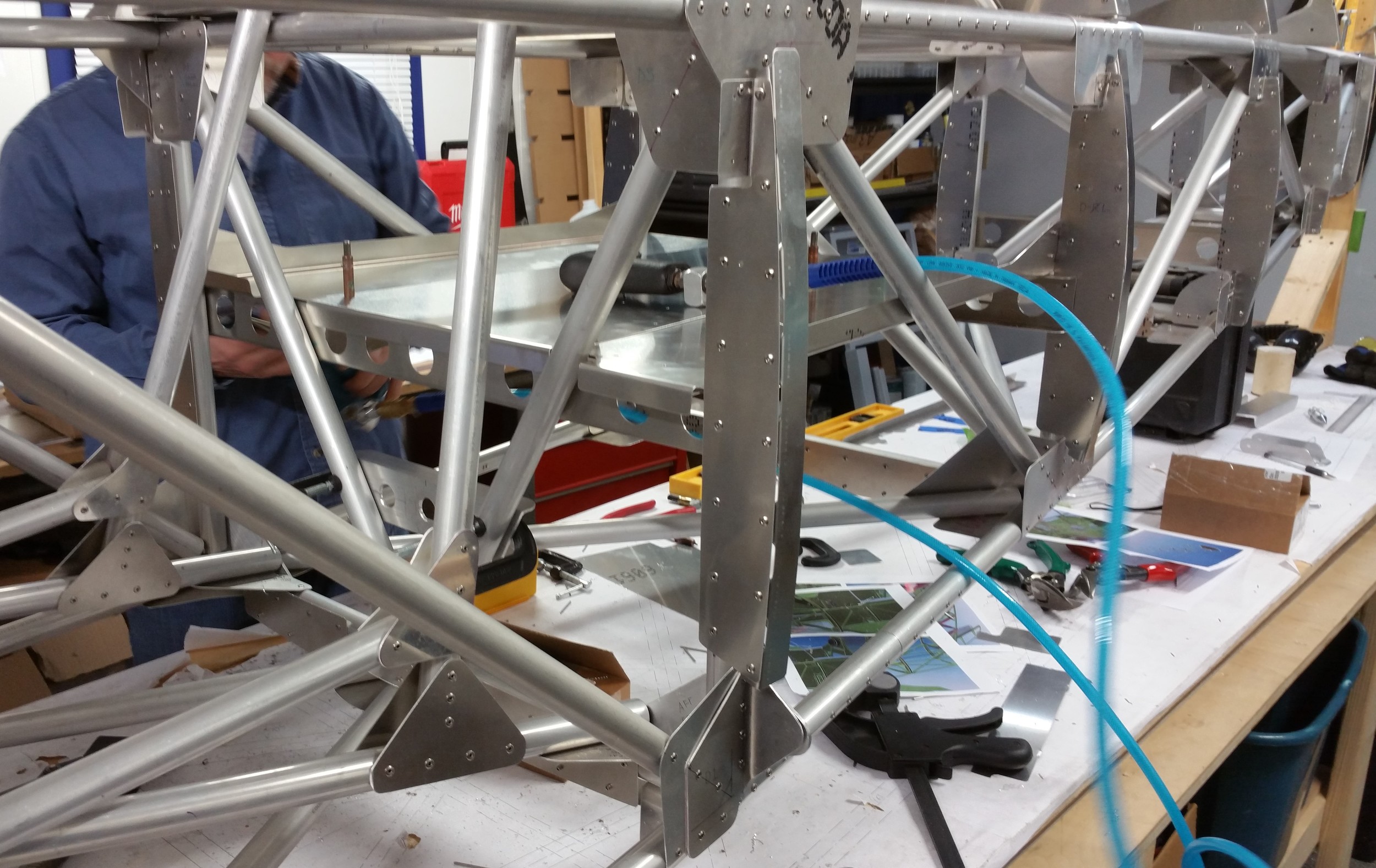

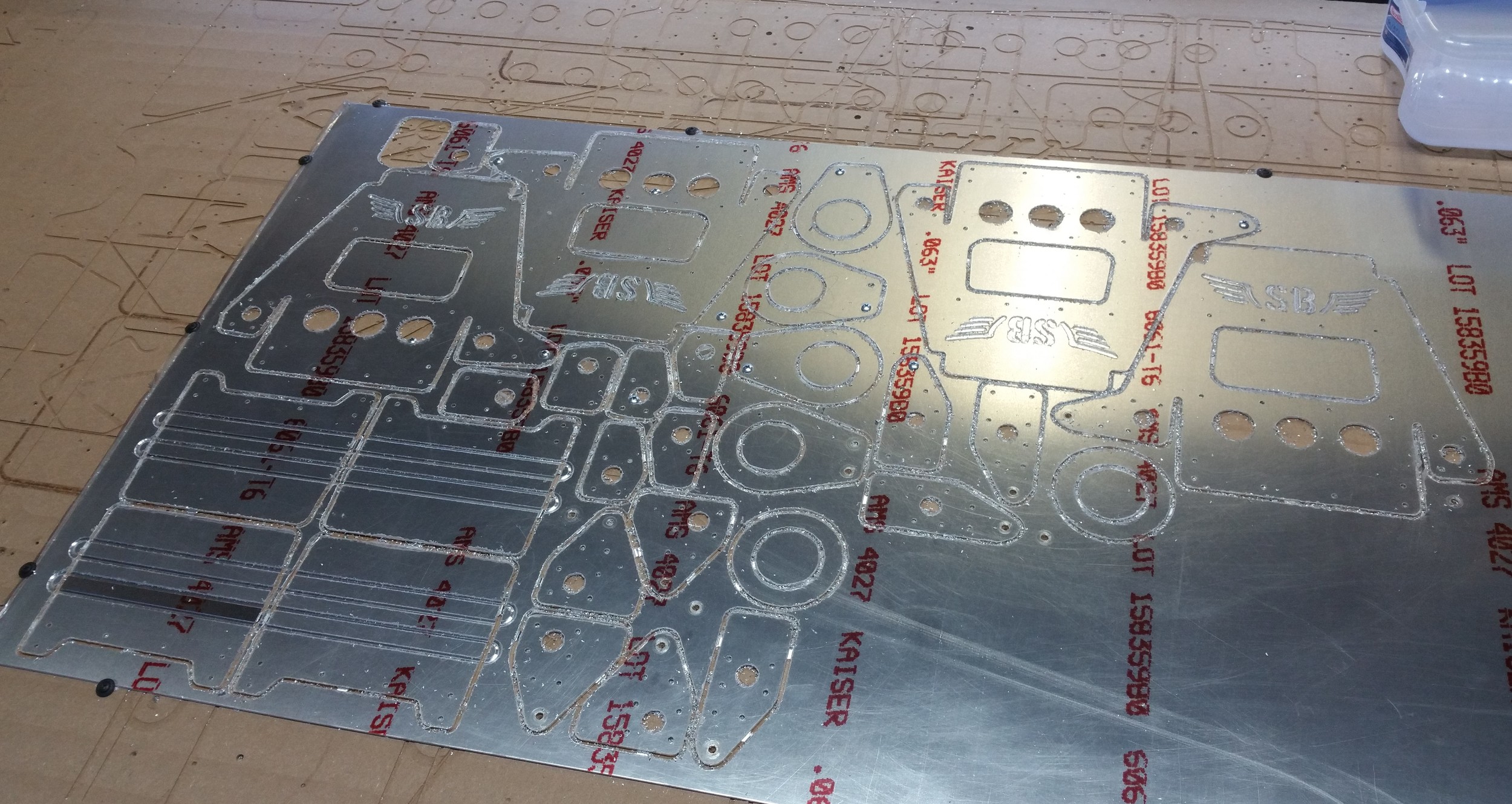

Also coming: Youtube channel, better Facebook presence, and real airplanes.

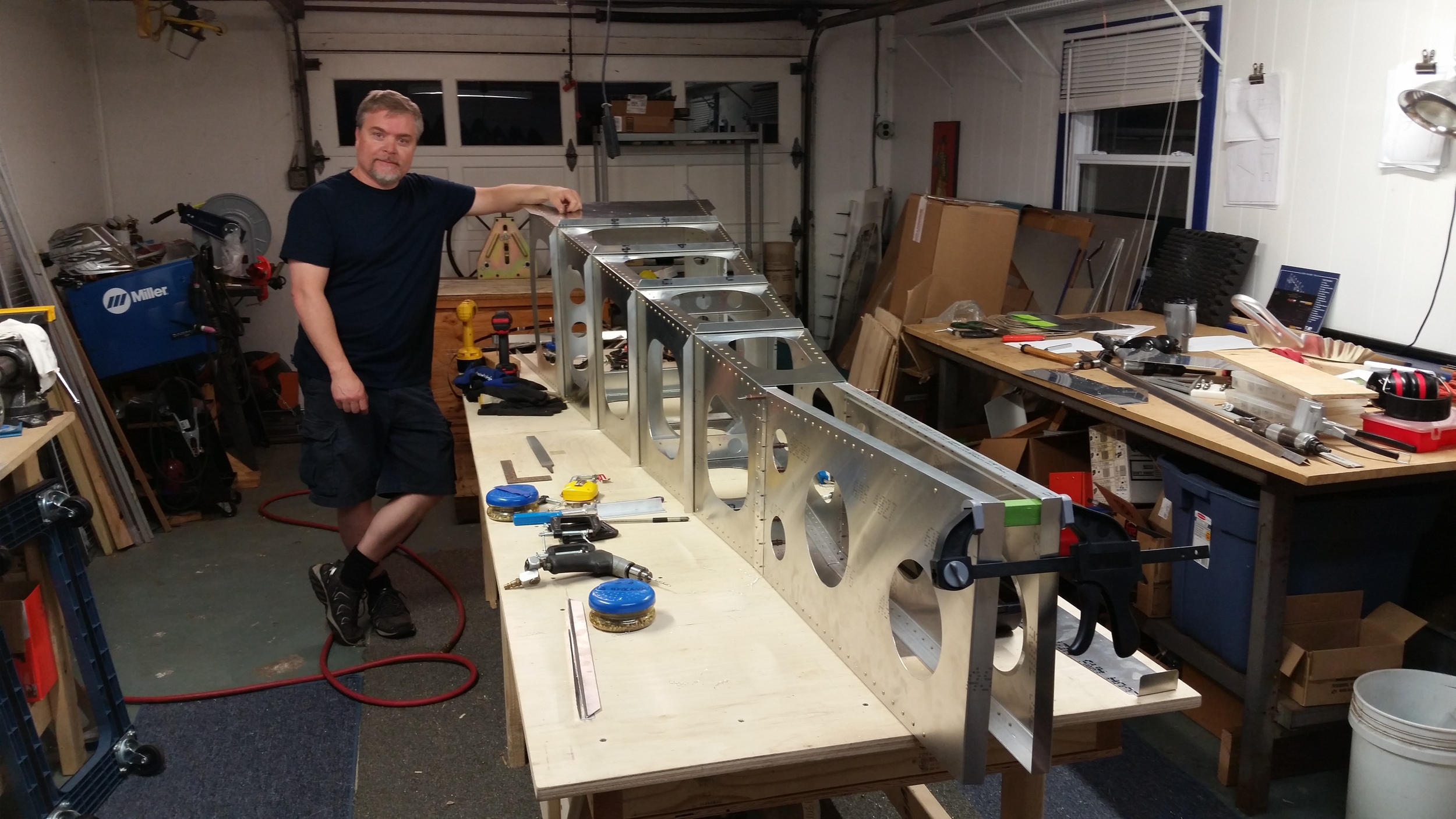

Shooting for having at least one flying LiteFighter by Sun N Fun 2017. Think we can make it?