Gravity always works

Hey there. We are still at it. Time to get you an update. Some great progress and a setback or two to discuss. In early October, we ran the engine a couple more times after the first start and were trying to adjust our idle setting in the carb. Paul stopped by and was mentioning that all the engineering calcs were not finalized because we needed a good weight and balance. Well, we need to start sending our calcs out for review prior to the flight test program. That is coming soon!

So, that changed the priorities and the second week of October we stopped doing the engine runs. We shuffled the shop around again and setup the plane to have everything on it. After Oshkosh, we left the tail and wings off because the mounted tail will not fit in the trailer. We were planning to take the plane to the airport and so reinstalling would have been wasted effort. But with the new mission, the wings went on, tail went on, all the fairings and the cowling and we drained the fuel tanks. We pulled out our industrial scales and made plywood pads the same height - so we could park the plane on the pads, then roll it onto the scales without changing attitude or anything. Paul got to supervise the effort and he logged the data. We did weights at a parked (inclined) position and then in horizontal level flight attitude - with and without a pilot. This gave us the data for a 3D location for CG (Center of Gravity). A recurring error was happening during the testing. The right (starboard) main gear weight kept fluctuating. So we did the tests by swapping the three scales. We then threw out the oddest set of numbers for each wheel location Like a 20 pound difference. Guessing that it has something to do with the spring loads in the landing gear legs. Pretty weird tho. We are going to do another final weight and balance shortly when the aircraft is ready for inspection. These initial numbers are good enough for the calculations as they have plenty of safety factor. Our empty weight came out to 837 pounds after taking the oil into account. 848 with oil. Heavier than planned, but not terrible for the design. We do have plenty of areas where we can optimize structure to reduce the kit version empty weight. But this is a prototype and it is what it is. CG location was “in the zone”, confirming our decision to go with the heavier and more powerful 7 cylinder engine. At first blush, a 250 pound pilot and full fuel is still in our initial calculated cg range with no ballasting fore or aft. Flight testing will determine how heavy a pilot we can handle in this particular airframe. We are pushing for a crew and bags weight allowance of up to 330 pounds. Real Americans are not as light as they used to be. For comparison, a real P-36/P-40 has a 200 pound max. crew weight.

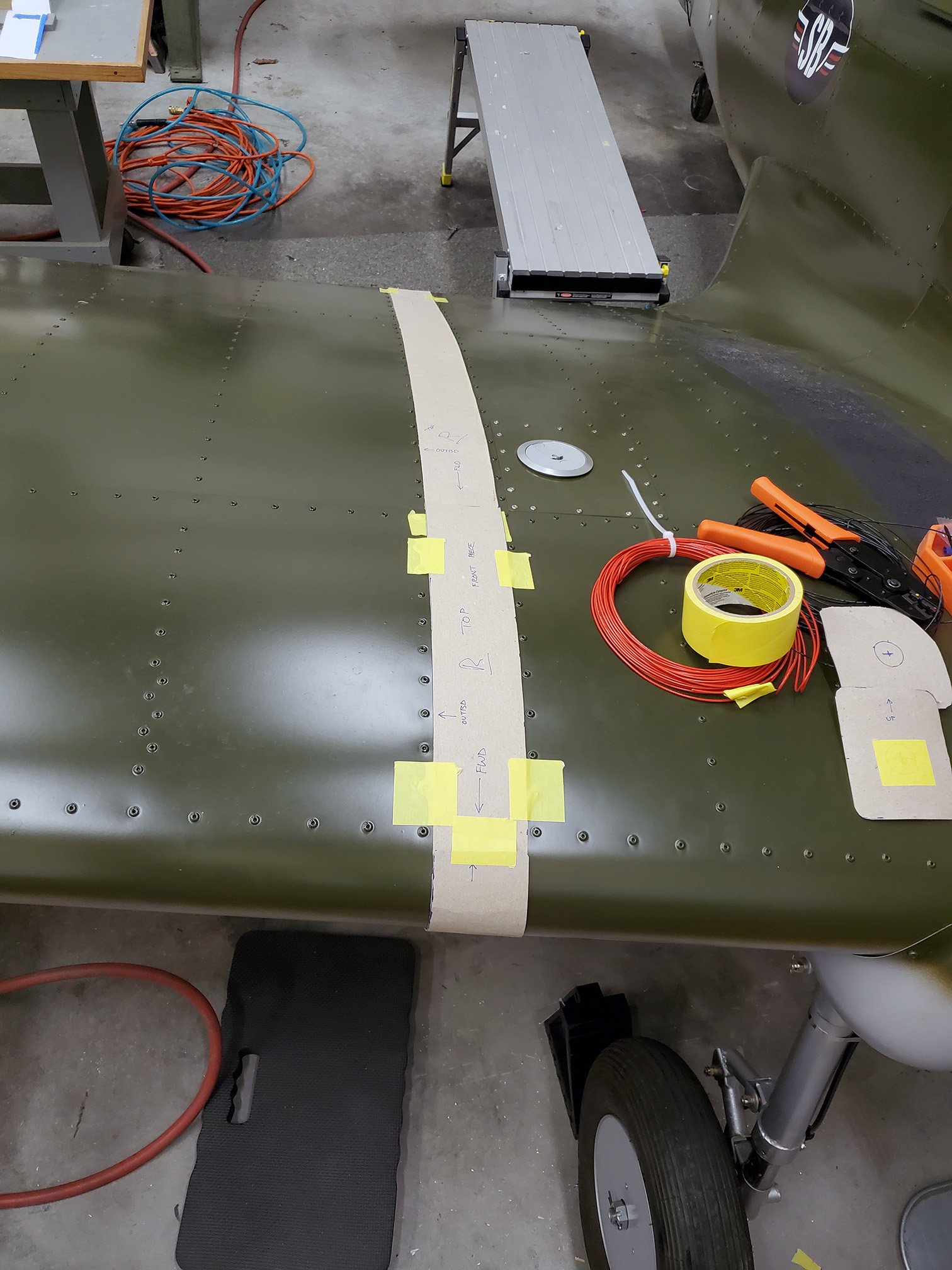

After the testing, we worked on wing gap strip templates and design. Going with a fixed trailing edge and tensioning the front of the strips to the forward false spar just behind the leading edge of the wing. Then a cap will cover the front at the leading edge. We will only have a few screws to secure it from sliding or vibrating out of alignment. Still waiting for time on the router table to cut them out, so they are not finished as of writing this. Very simple so they should be quick to fab and install. Likely at the hangar right before inspection.

We then took a serious look at the landing gear legs. We noticed that when we got the plane to Oshkosh, it had toe-in again. Our thinking was the scissor links were bending as the forks were thin material. The toe-in was even worse after pulling her out of the trailer back home. So the trailer ride really must have over-g’d the landing gear. The roads are terrible and we had the heavier engine this time. Our plan was to remake the scissor links all together and make them billet and stout to fix the toe-in. Well, upon further study, we found that the axles were bent. Not good as they are welded to the lower gear legs. A few people at Oshkosh mentioned the landing gear looked insubstantial and should be beefed-up. We agreed to that for the kit version. Well, now we have a serious problem with this airframe and we pushed-up the landing gear re-design to the second half of October. We studied the available wheels, tires, tubes, axles and brakes and settled on Matco 600F wheels and brakes with 600x6 tires. Had to also redesign the lower gear legs to fit the Matco 1.25” diameter axles that bolt-on with the internal caliper brakes. We are expecting delivery this week. We will set the dimensions and then mill the parts and get them swapped-out as soon as possible. I want to taxi this thing!

While waiting for the wheels (Matco is at full production and getting backed-up) we made the cowl flaps and are half-way done installing them. Looking awesome! They will be ground adjustable for now. Likely held full-open unless the engine is too cool. Scott did design an in-flight adjustable system for them. Will be an option for the kit. It is hard to retrofit that system with the current engine installation so likely won’t incorporate it into this airframe. Can readily make it into the design for the kit and adjust the engine installation to fit around it.

We are also waiting to run the engine again until we add a drain valve to the lowest exhaust pipe. #4 cylinder has a short section of the pipe that creates a low-point and any oil draining from the valve on that cylinder pools in that spot. Radial engines tend to have some oil draining by the piston rings as they sit parked. Especially on a new engine where the rings are not cut in yet. So I need my welder to add a stainless 1/8” npt threaded bung and then I will install a stainless tube and petcock drain valve. That should be sometime this week or weekend hopefully - everyone is either totally busy or out of work. Crazy times and it makes it very difficult to complete things. Then - back to running the engine and getting her dialed-in. Swap the gear legs and taxi her around!

Stay tuned!