Cyclone Ranger

We have still not been able to fly the plane after getting her back from Oshkosh and put back together. We have been doing a lot of engine runs and spraying a lot oil onto the grass next to the hangar. We had made an expansion tank and that helped delay the oil from starting to blow out the breather, but didn’t stop it. We are not talking about a little mist, this is a flow of oil when the engine is at full rpm for more than a minute and a half or two minutes. I’ve never seen anything like it. This proved to us that we need more venting area and better separation. So after exhausting all other options, we decided we need to remove the main oil tank and modify it. We did that on Saturday and was a big job. We had buried the tank into the fwd fuselage and cowl support structure. Never intending to have to remove it. Lesson learned - will make the next airframe much easier to r&r the oil system!

Now that we have decided to cut and weld the oil tank, we are busy designing the mods we need to do. Scott has been doing a lot of research into dry-sump and remote oil tank design. From what we are learning, the cyclonic method of separation is most common and successful. We need have to have something easy to fabricate and it has to have a very high potential of working in our application. We are up against the clock! We have to be flying and getting flight test data!

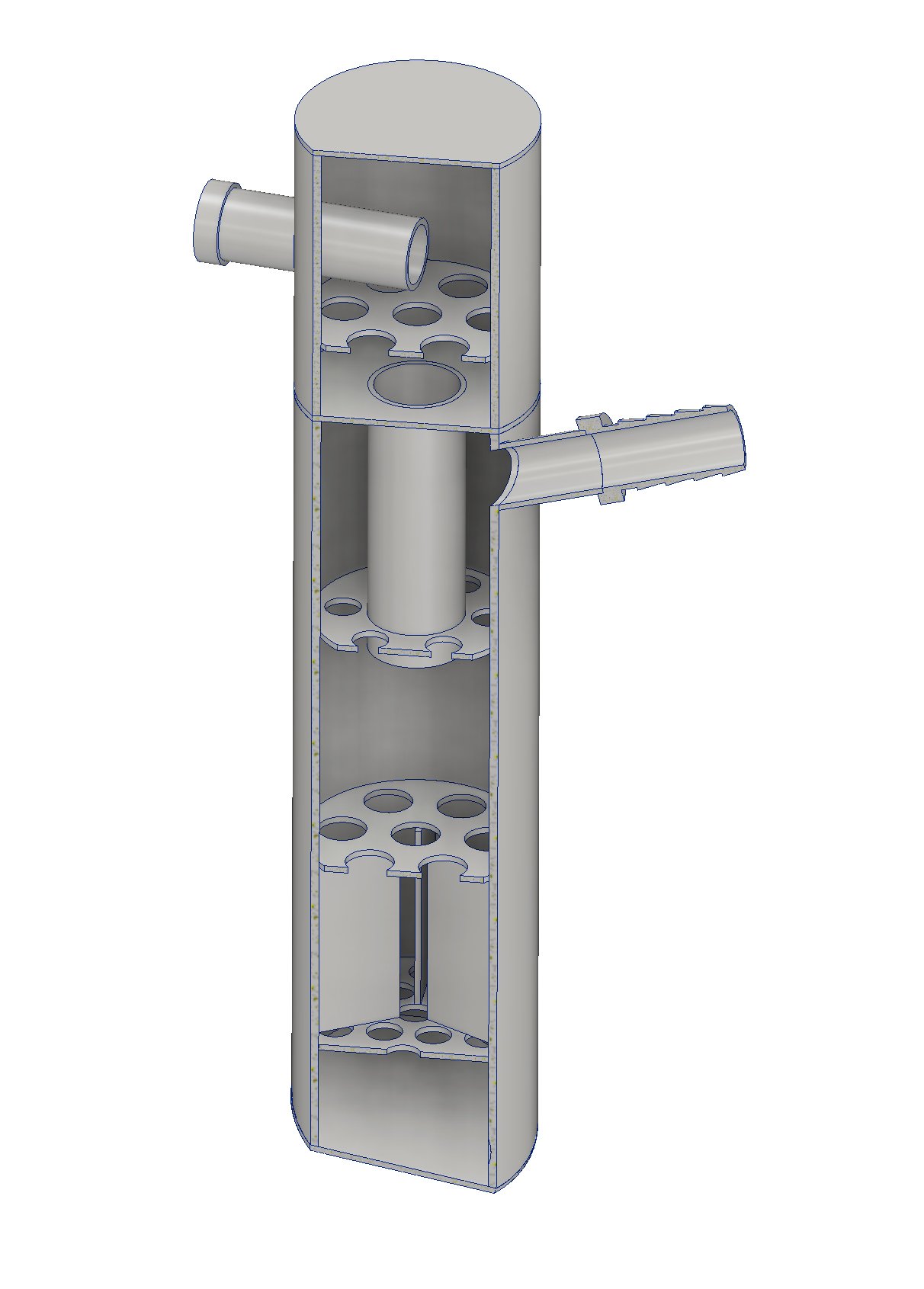

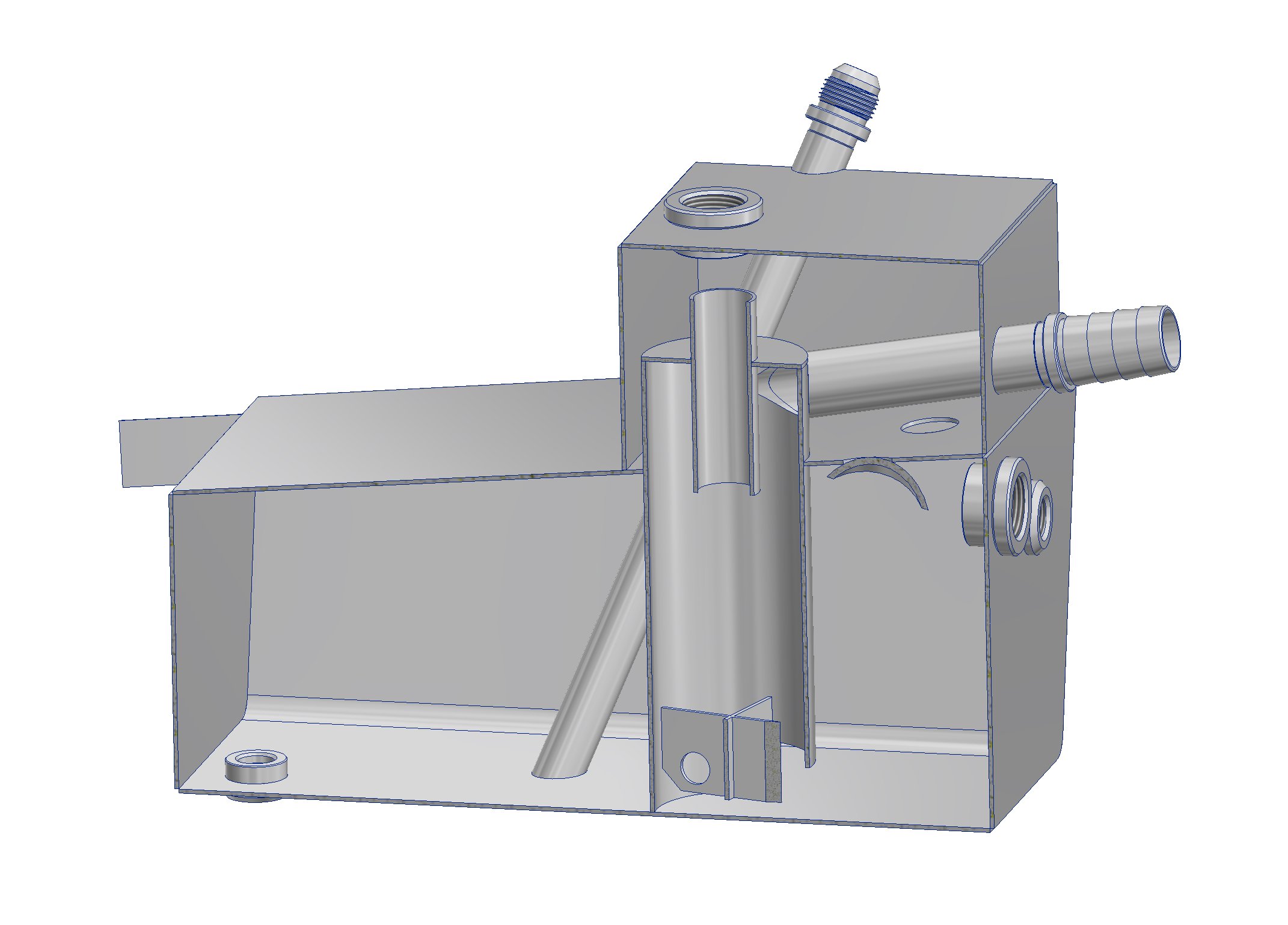

There are two main things we will do to it. The first is adding in a “dog house” to the top of our tank - to add as much air expansion volume as we can possibly fit. This is a box that is about 7” wide x 5 deep x 3 inches high. This air chamber will have a much larger bung welded to the top for a larger vent fitting and hose. We will add holes into the existing tank top for ventilation into and drain out of the dog house. The second mod we will do is add a cyclonic separator “can” to the inlet pipe on the inside of the tank. This will control the flow of the oil as it enters the tank and reduce foaming of the oil from entrapped air. Too much air in the oil will cause a drop in oil pressure - we are seeing this - and reduce the effectiveness of the pump and that is NOT GOOD! We also plan to modify the expansion tank we just made and turn it into a cyclonic separator as well - replacing the separator we have with a vertical tank style one. So we will have two separators in our system. One inside the tank and one external. Larger vent and breather hoses as well.

So stay tuned! We should have the mods done this week and get back to testing by the weekend - hopefully. Images to follow.