Fresh Start

Happy New Year! Best wished to all of you and your families. We made some progress, but not as much as I was planning for - but that’s what plans are for! I didn’t plan on getting a nasty cold for Christmas. Must have been getting it right as I was writing the last blog entry. Wife got it and gave it to me - I want to blame somebody! The gift that keeps on giving! Then Scott got it and it ruined the first half of our work week. Christmas was delayed, but good enough thanks to Dayquil. The rest of my family didn’t get sick or were just finished with it and we had a good time none-the-less. Plus, it was like Artic here for a few days over Christmas and after. I’m glad we didn’t get the snow that many had to endure. Just some rain and then freezing cold. Glad to be working inside!

The flaps are designed to be split flaps like the P-36 and 40 had - except at approx. 50% of span. On the next airframe they will be closer to 60% like the real ones - since we have more aileron than needed. This thing rolls quick! I am planning to use the electric drive motor out of a Pulsar build that was never finished. We are using a square tube for a main spar and then z-bent stiffeners, piano-hinge and .125 inch thick bar stock at trailing edge for the span-wise members. Triangular ribs made of several pieces riveted-up are spaced at normal intervals to make each flap rigid and transfer the airflow loads to the hinge and the drive assembly. We are adding in z-bent spars for mounting the flap drive system hinge blocks and the piano hinges. We will be modifying the inboard and outboard wings aft of the rear spars to accommodate the flap spars and the space needed for the flaps to fit up in there. The modified ribs will get stiffeners.

Over the week, Scott worked on tweaking the CAD models and 2D patterns and then the cut path files - trying to catch-up. I spent a lot of the week working on cleaning-up parts lists (not a very glamorous job) and cleaning/organizing work spaces - basement shop and office, our industrial shop and the hangar. Trevor helped with the organizing too. Also we have been rounding up tools and equipment from our multiple spaces and getting them to the locations we will need them (haven’t been making parts in a long time now). I keep telling myself to buy tools for all the spaces so I don’t have to drag them back and forth. Someday!

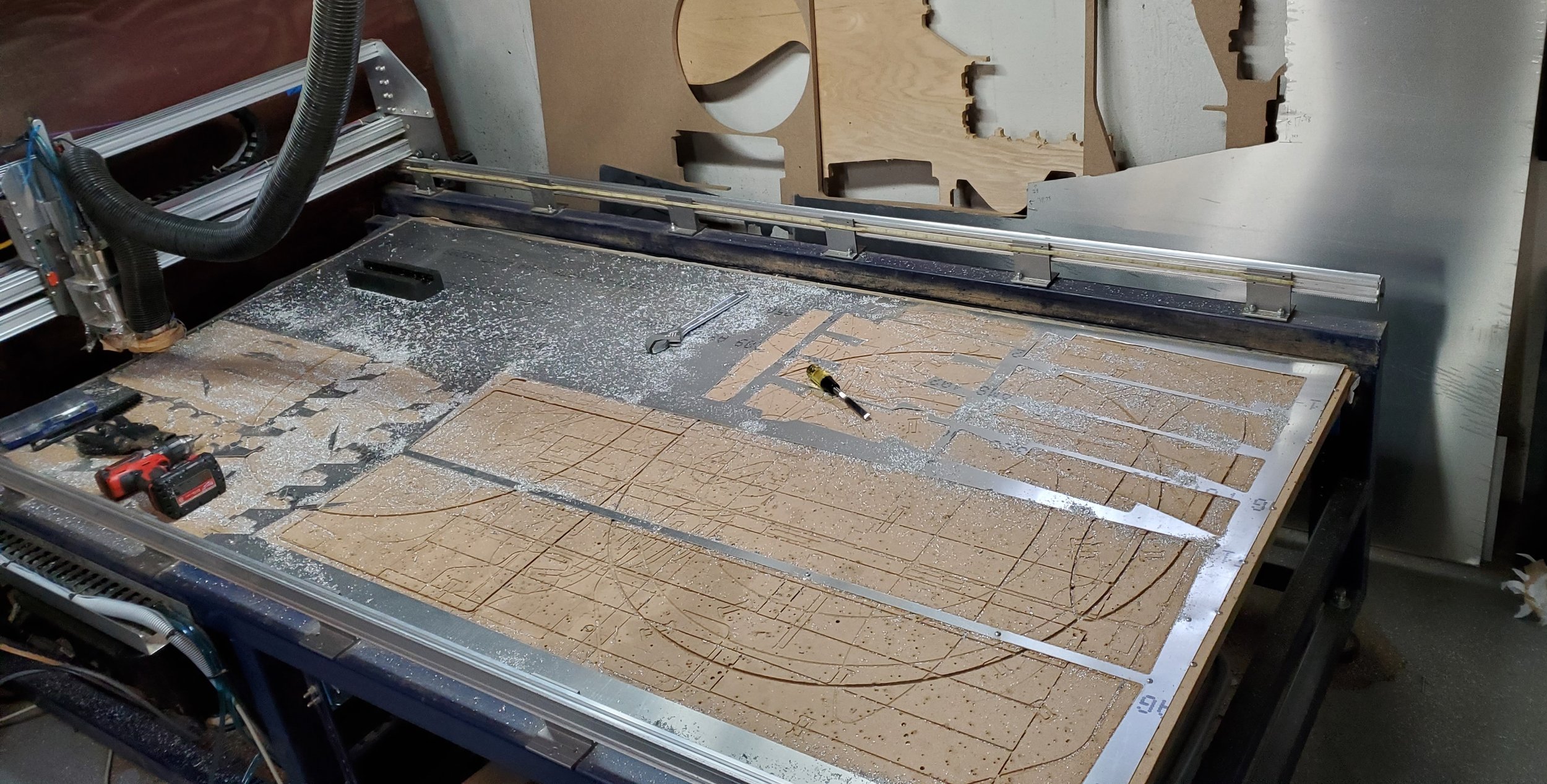

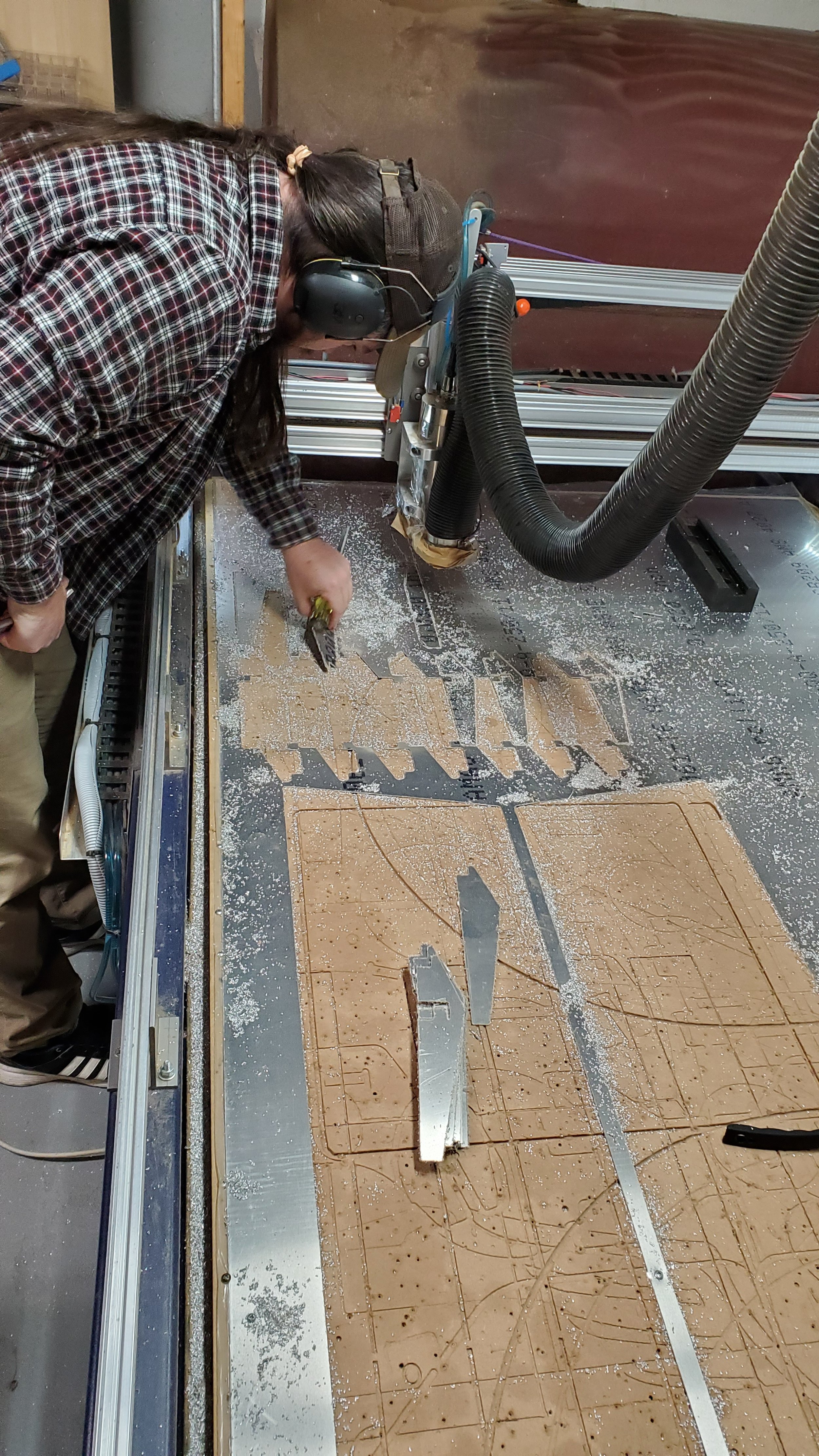

On Saturday and Sunday, we did cut-out most of the flap parts and the two skins with rivet holes on the 3D router table. Will be able to finish cutting the rest of the thicker parts out over the next few days. Then will bend the parts up with the box brake we have at our shop. The steel lasered parts have still not arrived - hope they show up soon. Then can get busy welding up the flap drive system parts. I have been chomping at the bit to build the flaps and we are going to hit it hard this week and likely a few more. Then attack the landing gear mods. At least that is the PLAN now! Fresh start to the new year!

Also, here is a pic of the wood prop we ordered from GSC Systems, Inc. in Canada. This is going to just be for testing purposes and likely just a few flights. NR Prop is still alive - literally! They are working when they can on making a new set of carbon fiber propeller blades for our hub. God bless them there in Kiev.