Sun N Fun 2022

SNF 22 was a great show for us. We were one of the busiest booths in our area for sure. I would say we had as many or more people through our booth as we did at AirVenture last year. We met so many people that are following us. If you made it to SNF and checked us out, please send me an email at: swatrous@scalebirds.com

We had the P-36A on display and our tent setup had brochures and business cards and shade. It was very warm and windy until the storms on Thursday, then cooler and windy. Lots of wind this year. We had our usual flags and signs. The plane was looking great and we were ready Tuesday morning. Wham, they started the show and we were busy from the start. We let a lot of people sit in the cockpit and almost everyone actually fit. Somebody was too tall and one guy was too wide - his shoulders were like 5 inches wider than the canopy rails - football or rugby kind of guy. He did sit in it tho, just couldn’t close the canopy. Most were surprised at how roomy the cockpit was. We didn’t have any brochures of the P-36 until about Friday morning. Scott brought his laptop and worked on it during the week to get a nice one done. Will link it in the website. We ran out of business cards and the new brochures Sat and made more for Sunday. We were that busy!

I was amazed by the number of actual warbird pilots, owners and mechanics that stopped by and checked out the P-36. Thank you all. All of them really liked it and we may have won some kits sales from them. The real stuff is so expensive, they cannot just play with them. Heck, the cost of one of our kits is like a propeller blade. They appreciated that the feel of the plane is very WW2 and told us that we got it right. The Verner on the front and the cowl flaps was what really caught there attention. The cockpit completed the deal for them.

We had several interviews and good press coverage - despite not pushing for it yet. We had been graciously offered to be highlighted by the SNF media - we turned it down as we are just not quite ready for a big marketing push. Total concentration on getting her flying and get the real data and adjustments made to the kit design. The idea was a soft launch at SNF and then we will do a full launch at AirVenture 2022.

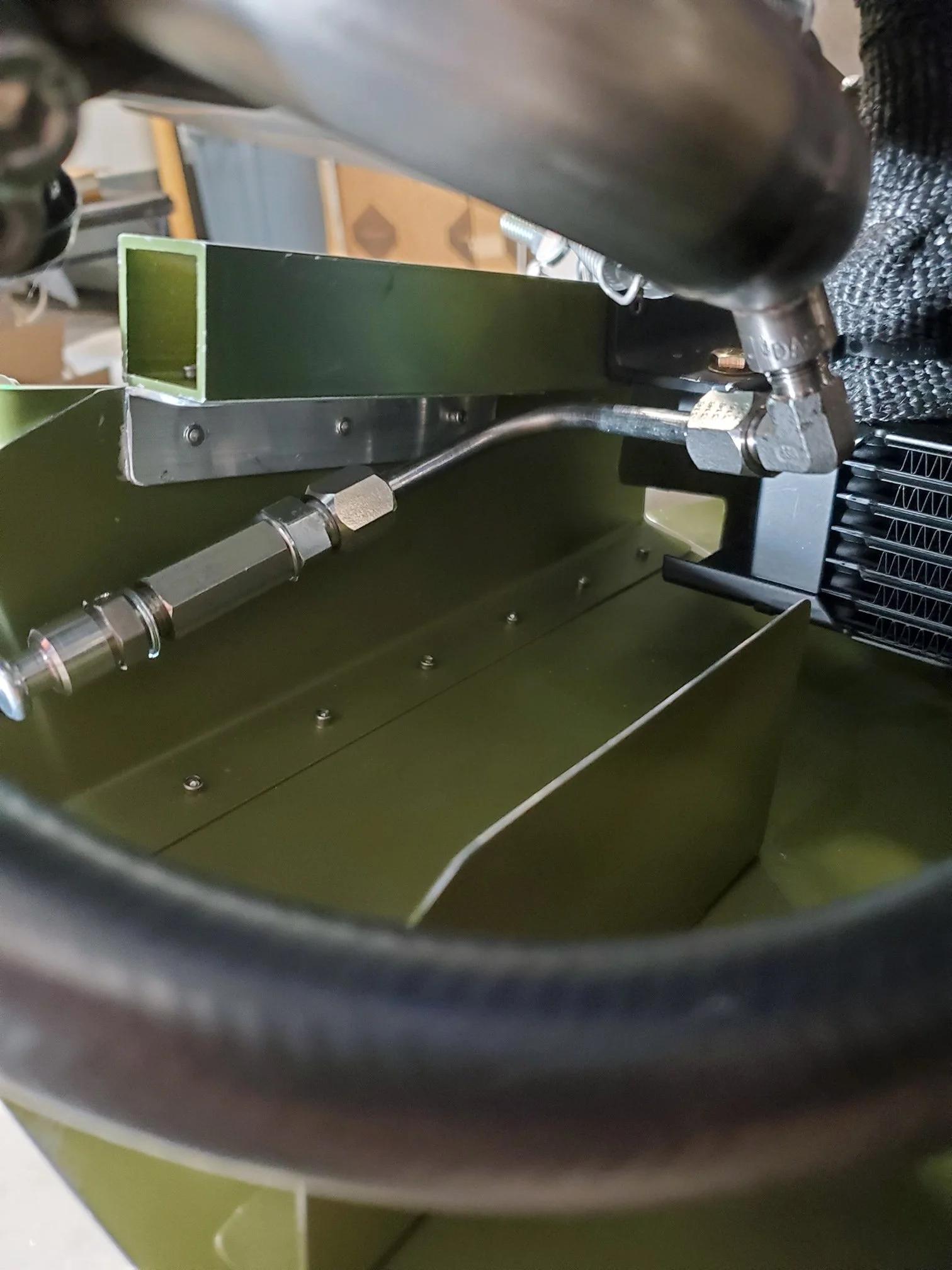

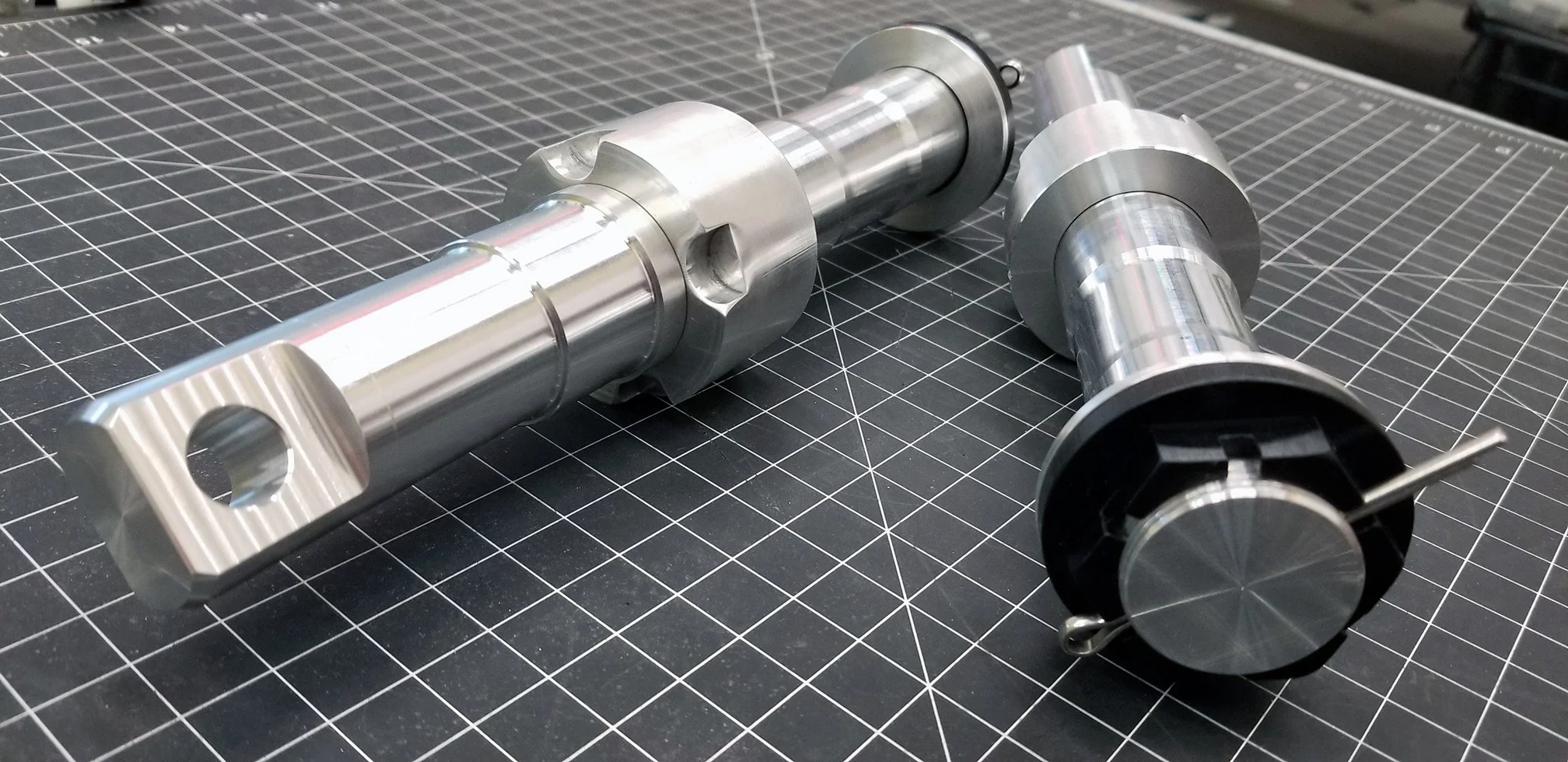

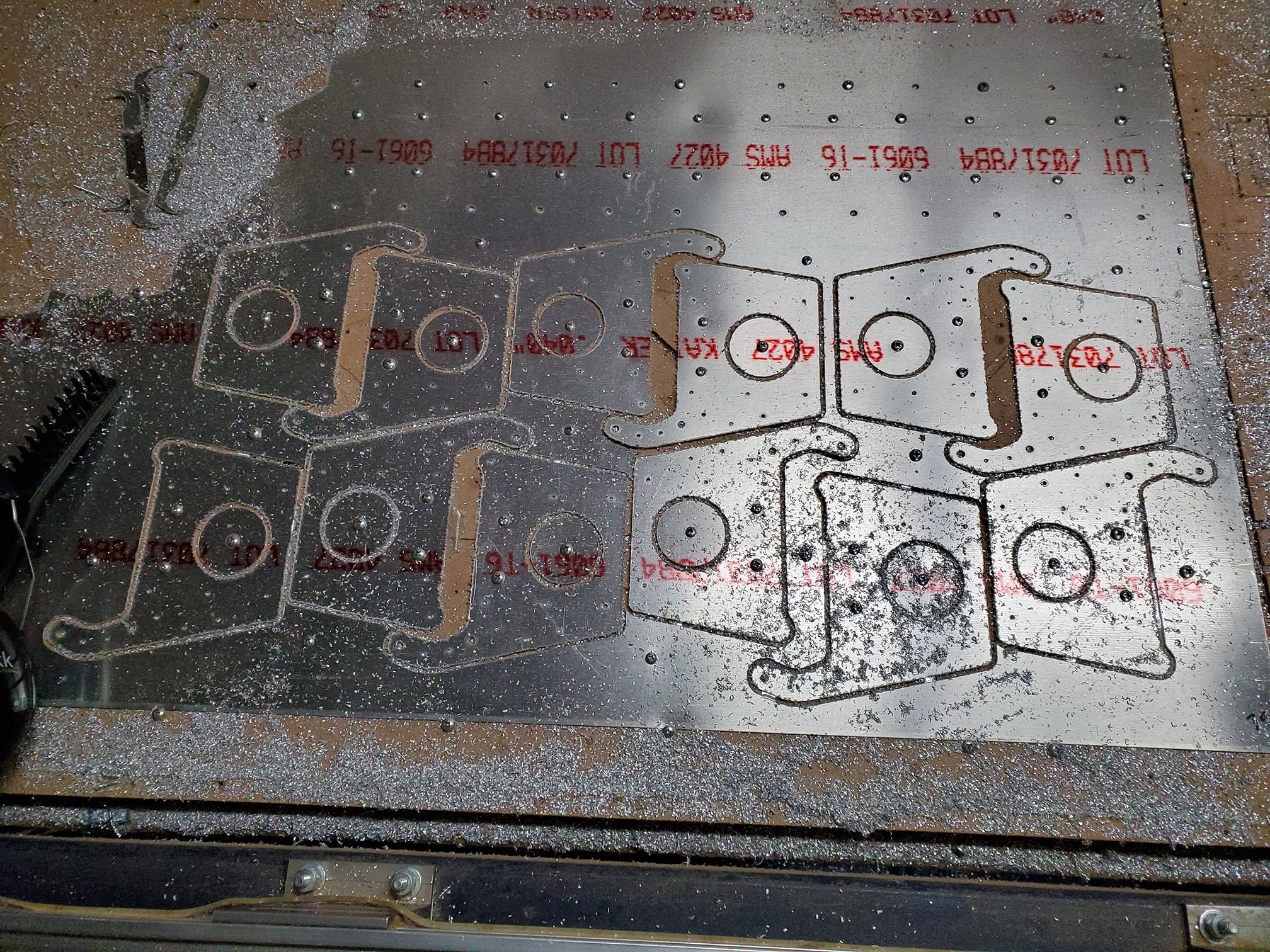

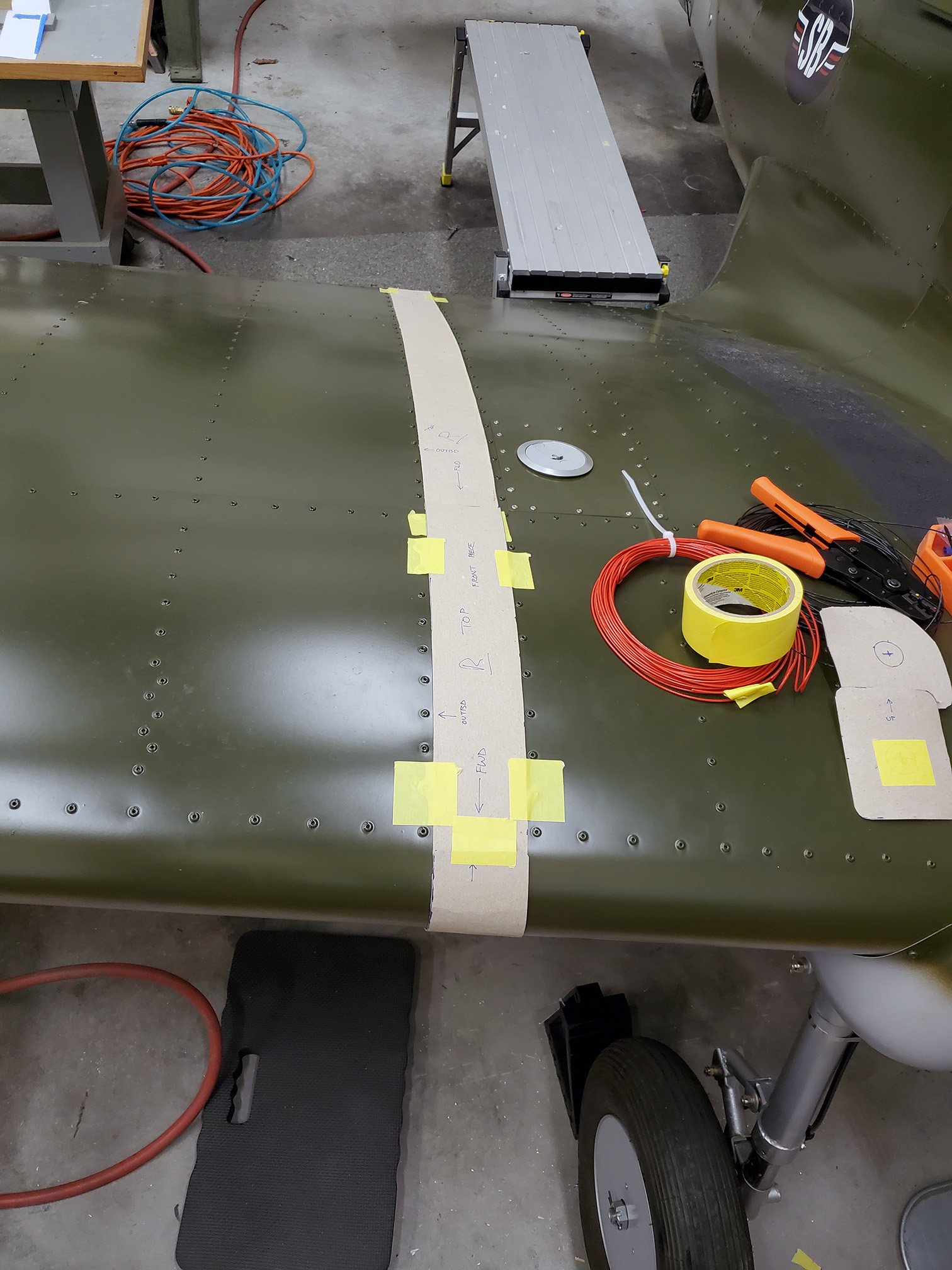

We worked some heavy hours to get the P-36 ready for showing and we made it. She was absolutely done - except for two parts. The canopy latch mounting bracket and the spinner. There literally was no time left to make those before the show or we would have. Scott finished up the landing gear parts and everyone pitched-in to assemble and install them onto the plane. Having the new gear legs was critical path. I am super excited that they not only look awesome, they seem to work better and stayed straight and true through the trailer ride to and from Florida. No, we couldn’t fly her down. Had to take her apart and load her into the car hauler box trailer we own and drive her down to SNF. Believe it or not, highway 95 is terrible in many locations. I thought NJ was rough roads, SC and GA had some terrible spots. We had real time fatigue testing on the airframe. Airplanes should not be treated like that! We will be inspecting everything in the next two weeks as we are pushing for the FAA airworthiness inspection. So far, initial observations show no damage except for a wing tip. There is always risk of trailer rash and I can’t wait to be able to fly the plane to shows instead.

Not everyone of the team members could make it to SNF this time. Aaron, Scott, Karen and myself did make it. A super treat was Aarons parents came to the show and stayed with us for a couple days. We put them right to work! Great support and advice! Shin was planning to fly-in Thursday night and stay till Monday, but the weather Thursday was terrible and the airline canceled his flight. Nothing available till Saturday night so it wasn’t worth it for one day at the show. Karen was scheduled to fly home on Thursday and that was canceled as well. It worked out well as she booked a flight on Friday and her and Aaron flew back on the same flight, same row. Aaron had rented an economy car and was given a convertible Mustang. That never happens to me. A bit jealous. So they could ride together and that helped the booth staffing on Friday. It was just Scott and myself Friday afternoon and then Sat, Sun and I was surprised at the amount of customers the final weekend. Not just the local airshow people, but seriously interested buyer types.

We had a lot of interest in the Verner Motor line of radial engines. I would say they are getting to be popular with all sorts of sport aircraft. Karen and I were invited to the Hatz Association lunch on Wednesday and we were treated very well. Steve Wolf and Kevin Kimball were guest speakers. So great stories and info about the Lockheed Vega restoration Kevin’s shop is doing. Steve and Kathy Hirtz had just had their anniversary a few days earlier and the group surprised them with a cake. Great time!

Scott and I were staying in FL a few days after the show, so we broke down the booth on Monday and with just the two of us, took most of the day to pack the trailer - in strong winds. We then had dinner with Steve and Kathy. Spent Tuesday with Steve and he took us to Kevin’s shop at Tangerine field North of Orlando. I was in heaven. Kevin, his dad Jim and his son Kallin gave us a tour while Steve was bending up some spar web blanks for the elevators on his P-47D project. They showed us their CNC machines, old school tools and the Vega project. It is so much cooler in person than the videos of it. We also saw some Stearmans and one was an Air Mail model. Award winners and perfect in every way. Steve’s P-47 project is stunning too! It will no doubt be the best replica of a P-47 ever! I wanted to stay another day with Steve and go see his buddy Jack Hallet, but I had to get to NC to work on a customers aircraft and get his 3V motor running for him.

We did stop in and see Brian Kelly in Spruce Creek since it was on our way to NC. Had to check out his RV-8R engine installation and cowling efforts. Looking great and should be flying about now. He loves the power of the Verner 9S, but he is having cooling issues, so the flights are super short - no time to get real performance data. It climbs a lot better though. He is modifying the cowling and baffling to get improvements. Some of those are causing more drag, so top speed is suffering - again, only short flights so hard to tell. Im guessing he will get the bugs worked-out pretty soon. Brian gave us a golf cart tour of Spruce Creek - that was a real treat as I’ve always wanted to see the place. Very cool! After that we drove to Elizabethtown, NC.

Our new customer in NC has a JH Aircraft, Corsair ultralight with a Verner Motor 3V engine installed from the factory in Germany. He also has the trailer for the airframe. This is the first production example in the US. The customer contacted us for help with getting the aircraft flyable. He spent a ton of money and was taken for a ride. The engine wouldn’t run and never was run to full throttle. The dealer had held onto the airframe for almost a year before delivering it. Tried to get it flyable but didn’t read the manuals and could not figure it out. So, in the interest of helping him and Verner’s reputation, we worked on the craft for two full days to get the engine running again. The dealer support was non-existent and one of the dealers helpers had even bent a wingtip bow with a hammer! Buyer beware! After trying to run the engine and failing to do so, it turned-out that the fuel system was the primary issue. We had to relocate the fuel selector and hoses - it was above the fuel tank and had an air bubble the pump would not overcome. Then disassemble and check the carburetor - which was fine after all, and adjust some wiring and install a new battery. The dealer had tried to jump start the engine and this ruined the lithium battery. Plus, a lot of head scratching and figuring. The throttle was a T handle on the instrument panel, terrible as you can’t make fine adjustments to rpm. The 3V will shake at low rpm. The graphite tubing space frame of the ultralight Corsair allows the instrument panel to shake wicked bad. So, we got it running, but not fine tuned. The owner will need to address the fuel tank leaks and the throttle has to be replaced with a quadrant style. Then we can go back and work on the engine mixture to get it flight ready. We learned a lot about what not to do in designing an aircraft.

We got back late Saturday night and had Easter with family. The P-36 is now safely in its hangar at the Westerly State airport in RI. I need to clean the hangar and re-assemble the plane. We have to prep for our inspection and then flight testing. We will start posting videos of the process and first flights for sure. So buckle-up and hang on!