Designing Mods

Been working on designing the flaps and landing gear mods. Taking longer than anticipated - mainly due to the day jobs we have. Sorry, but the Navy wants it’s toys and really needs them. Also, its that time of the season where everyone is busy and has social things to do as well. Can’t be anti-social. That said, we are just about ready to order material and parts. I can’t wait to start the fabrication and modifications to the wings. I really like working on airplane sheet metal because it goes fairly quickly and you see the results right away. I have the week off between Christmas and New Years - gonna work on the plane as much as possible.

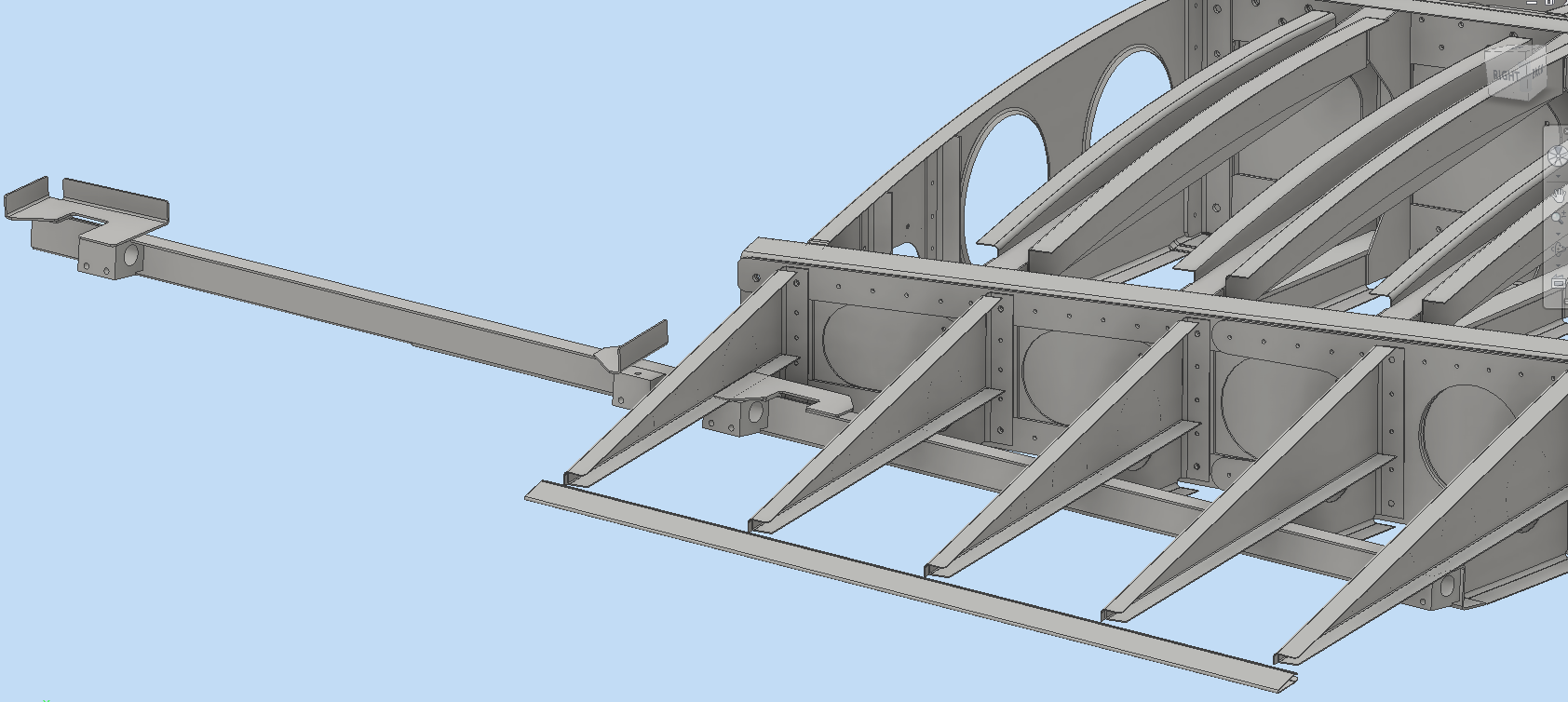

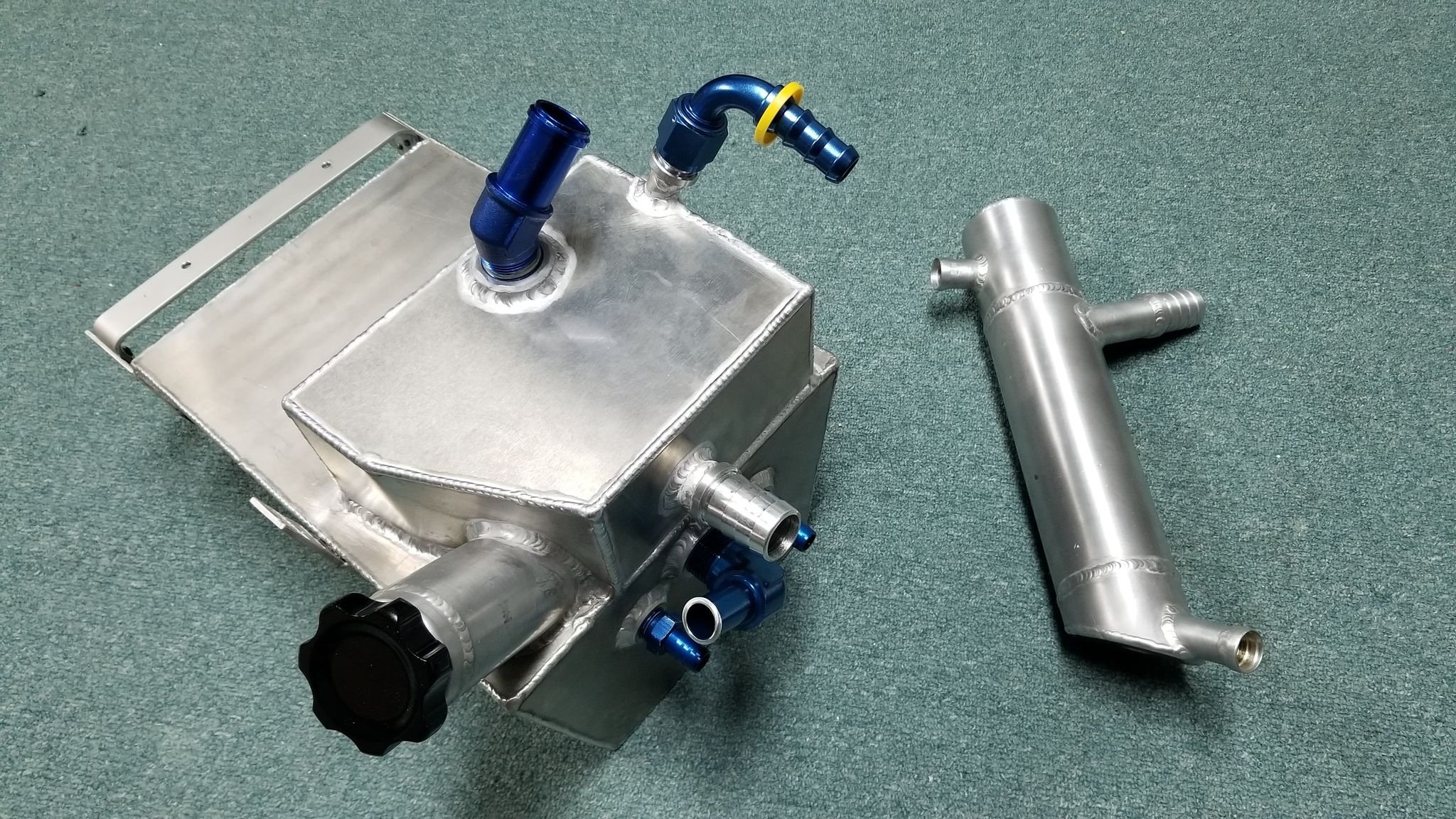

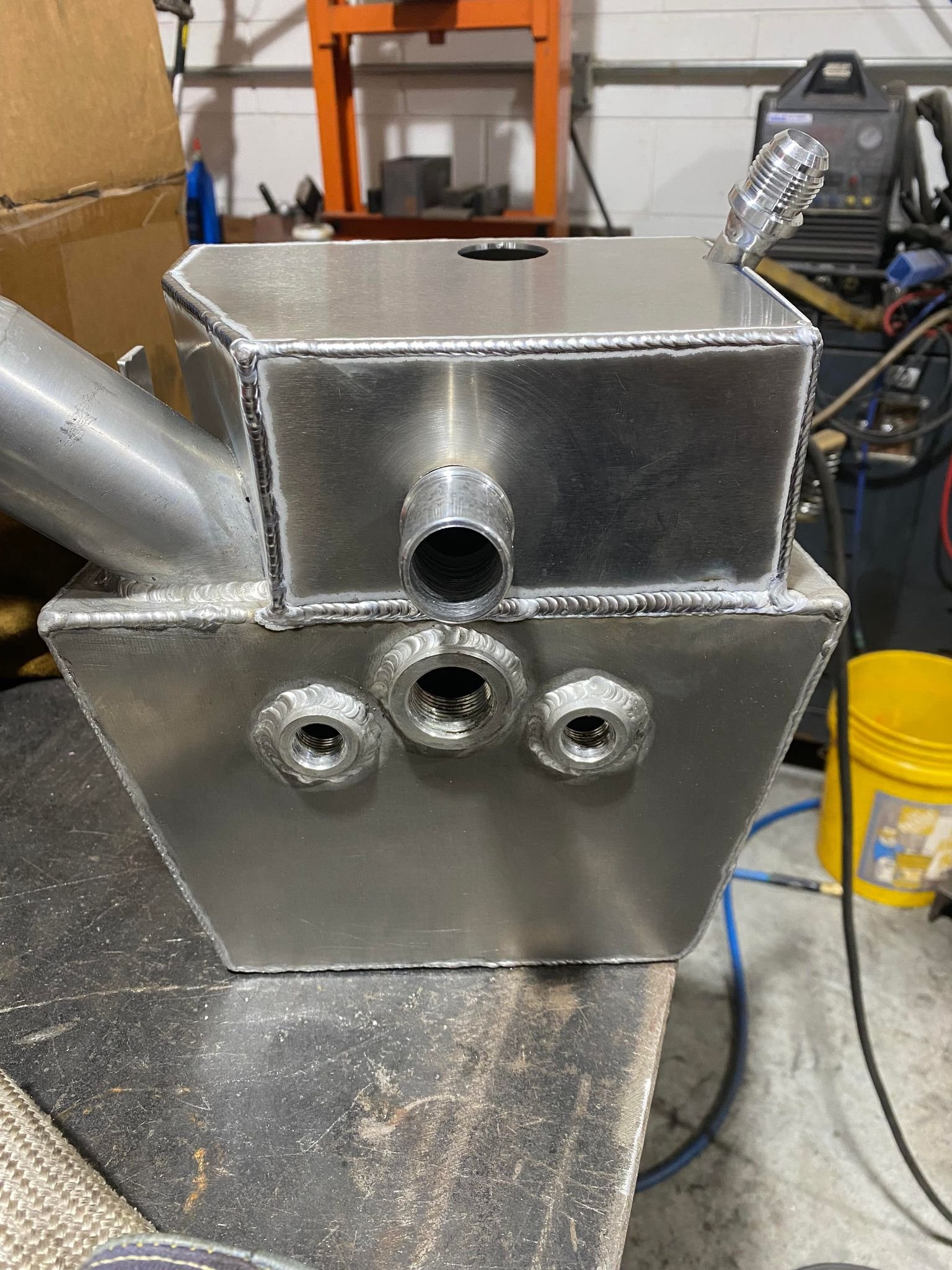

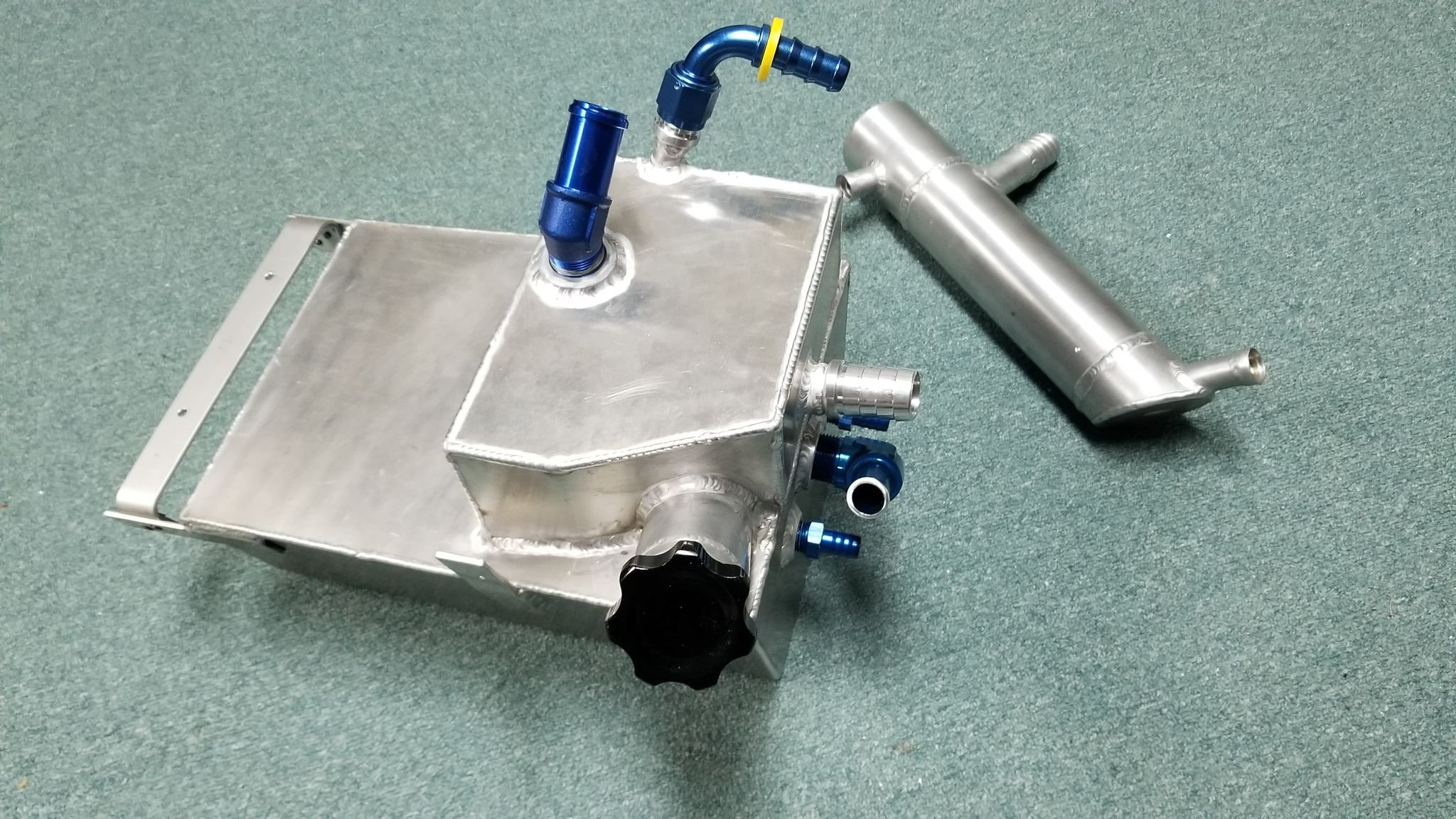

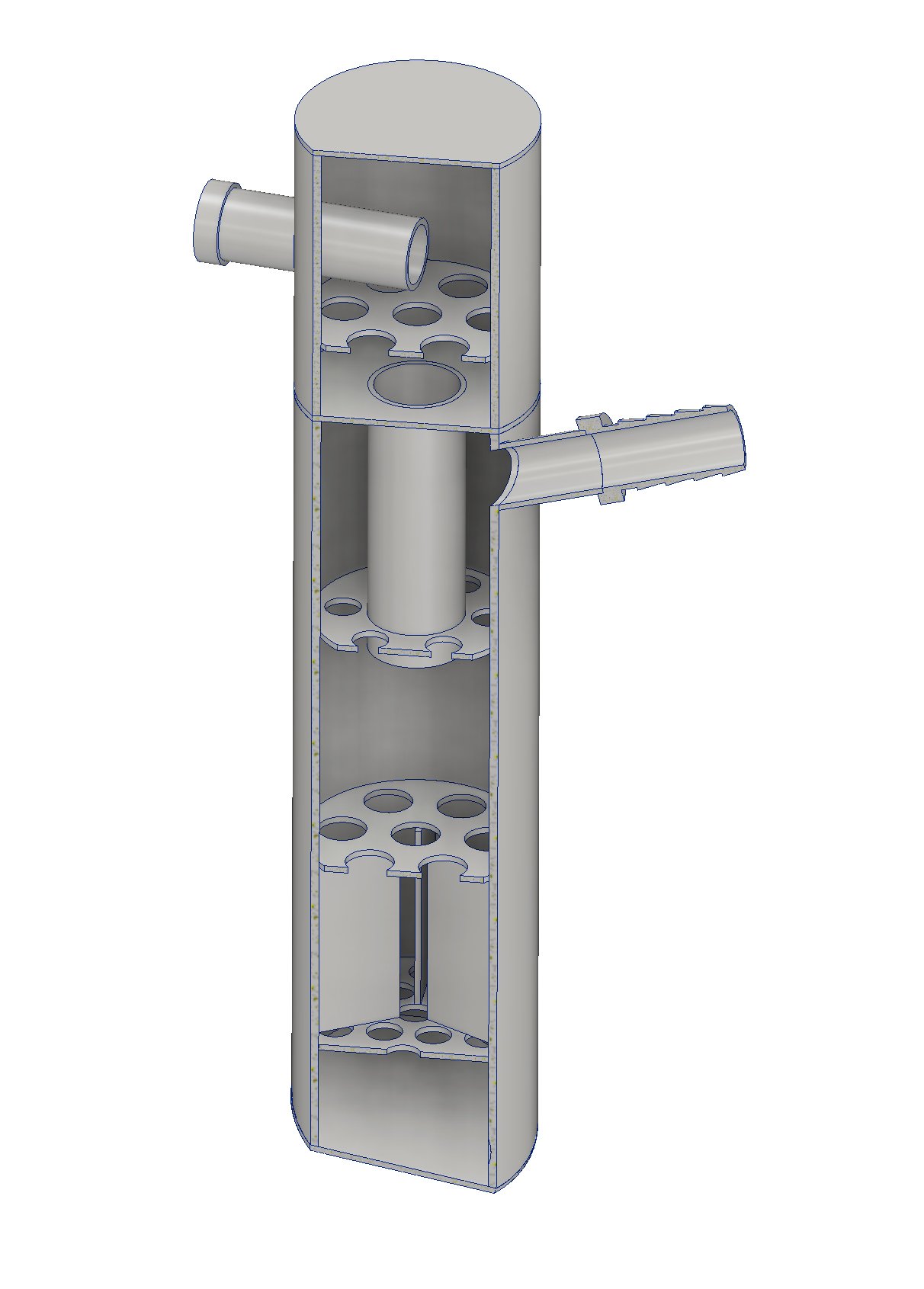

Scott has the landing gear changes modeled and will get to ordering parts and material this week. The lower leg/struts are going to be chromed steel with a .125” wall thickness. They are fairly short - about 12” so wont weigh too much. The rest is going to be delrin and aluminum internal parts which will weigh a lot less than the heavy springs we have in there. So hopefully we will loose weight overall. Having oleo (oil and compressed air) gear legs will dampen the landing bounces much better than the spring gear legs. Hopefully!

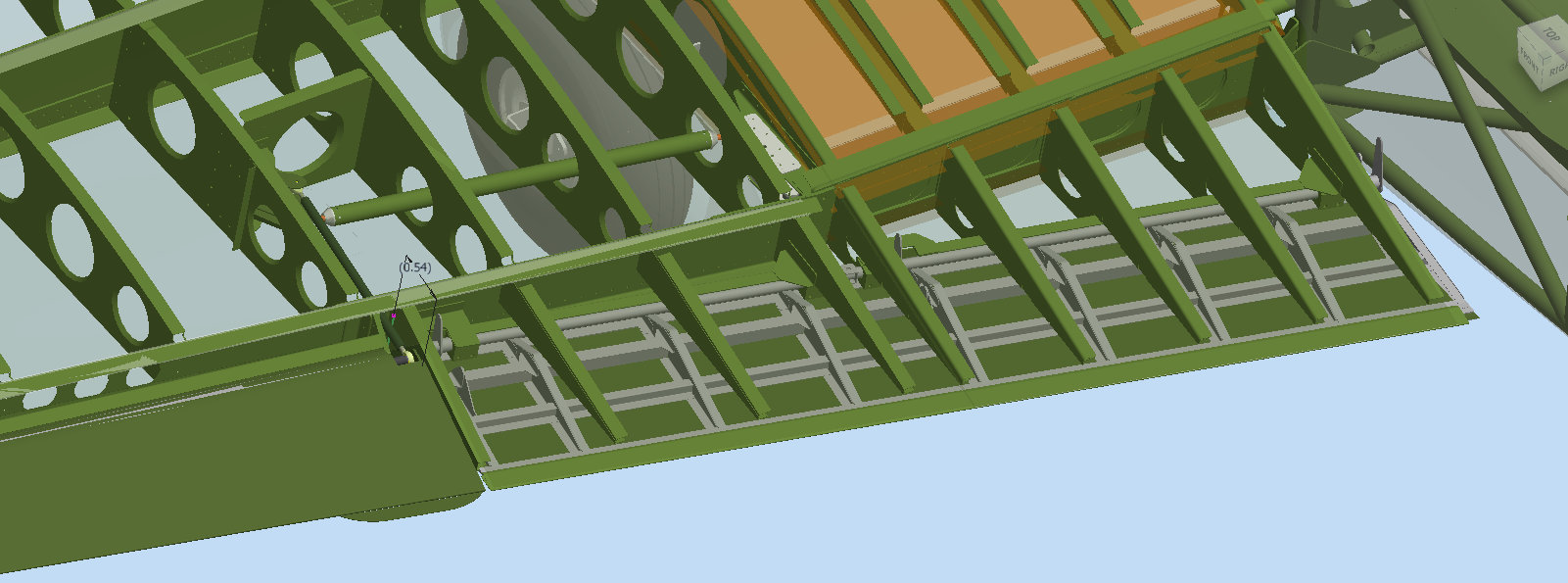

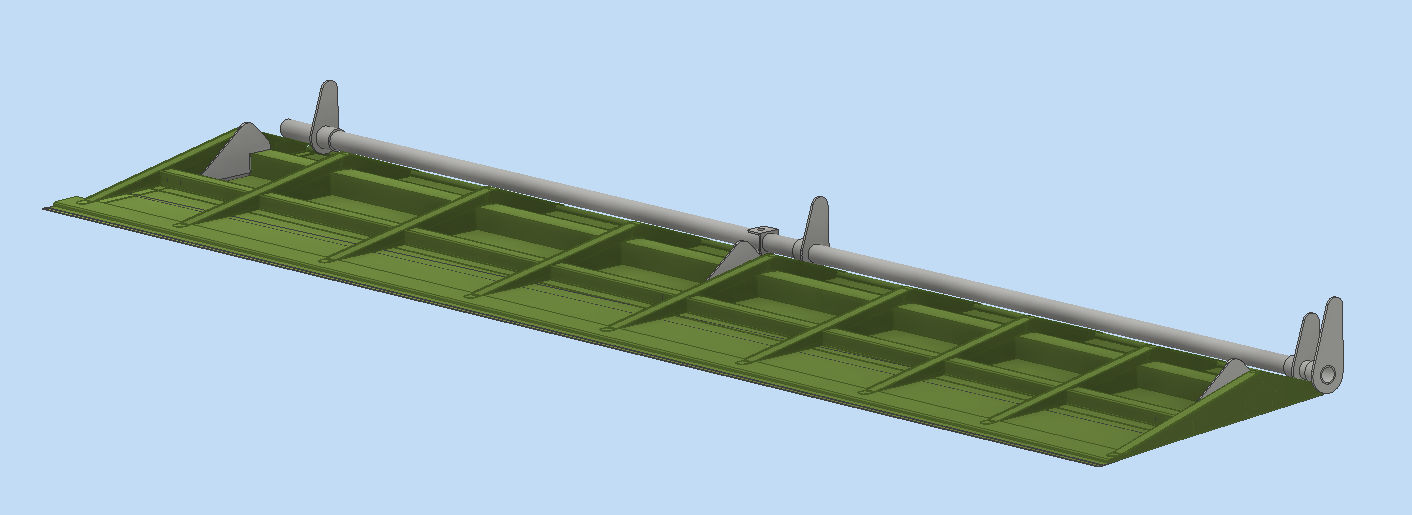

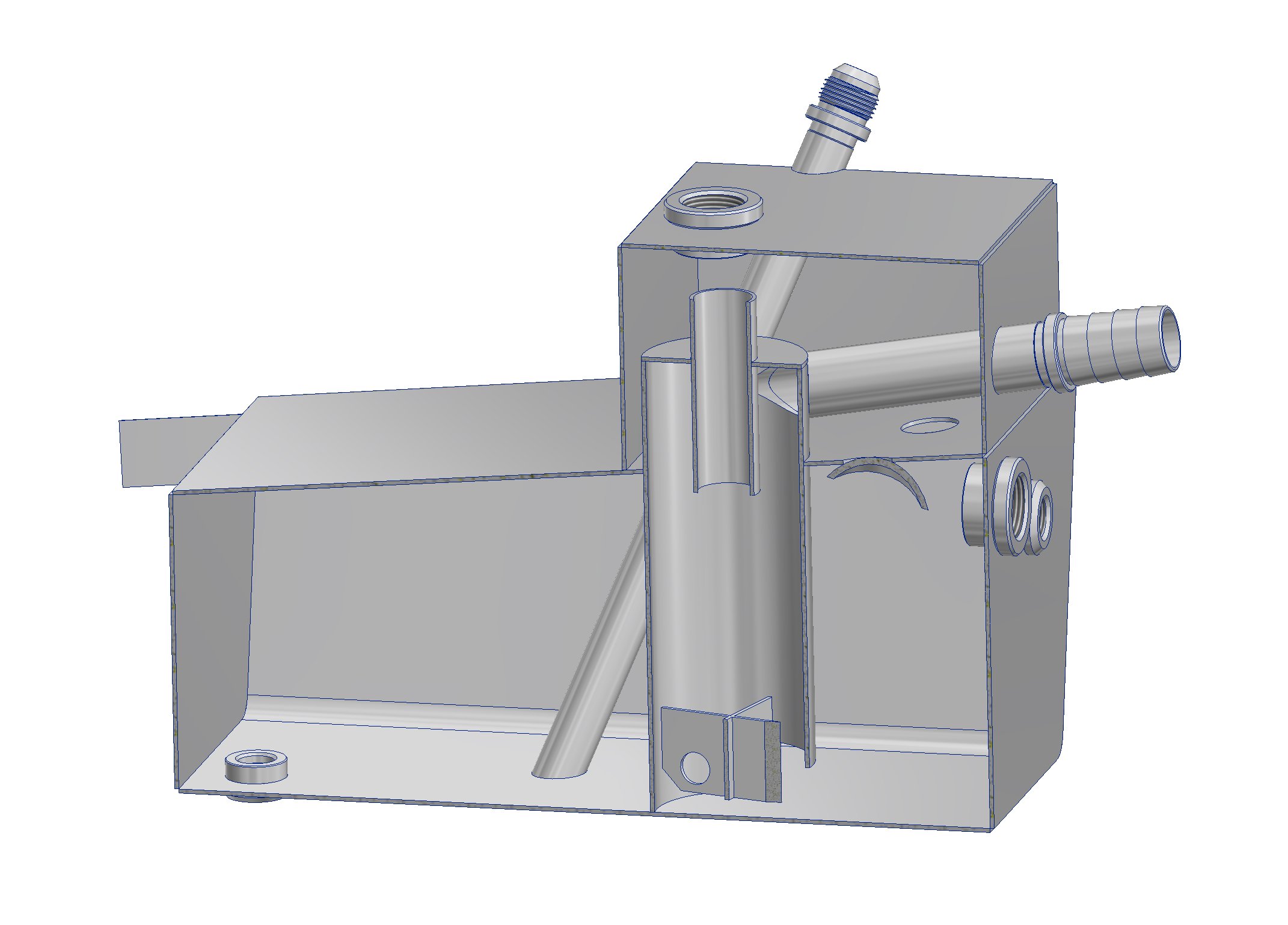

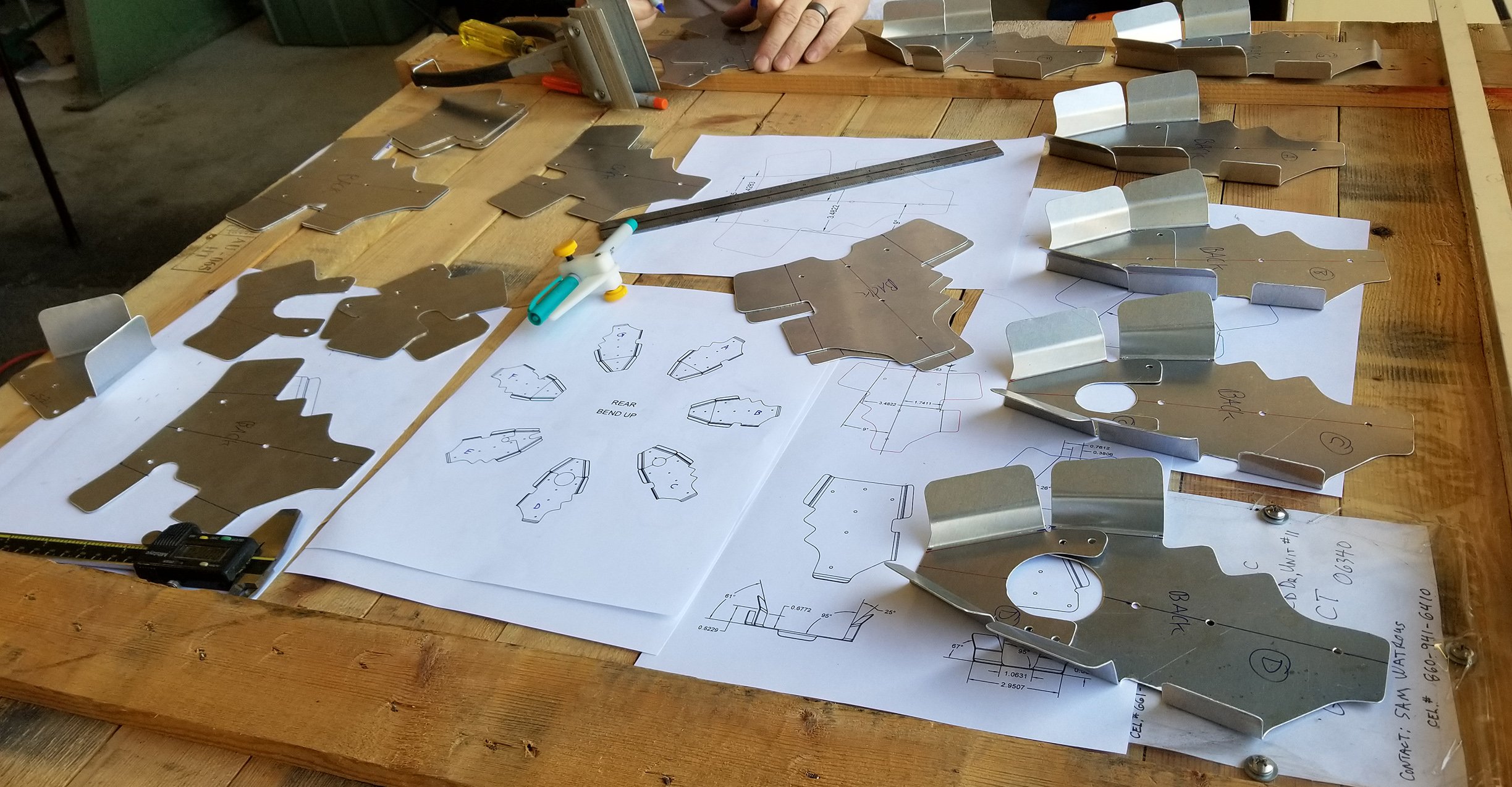

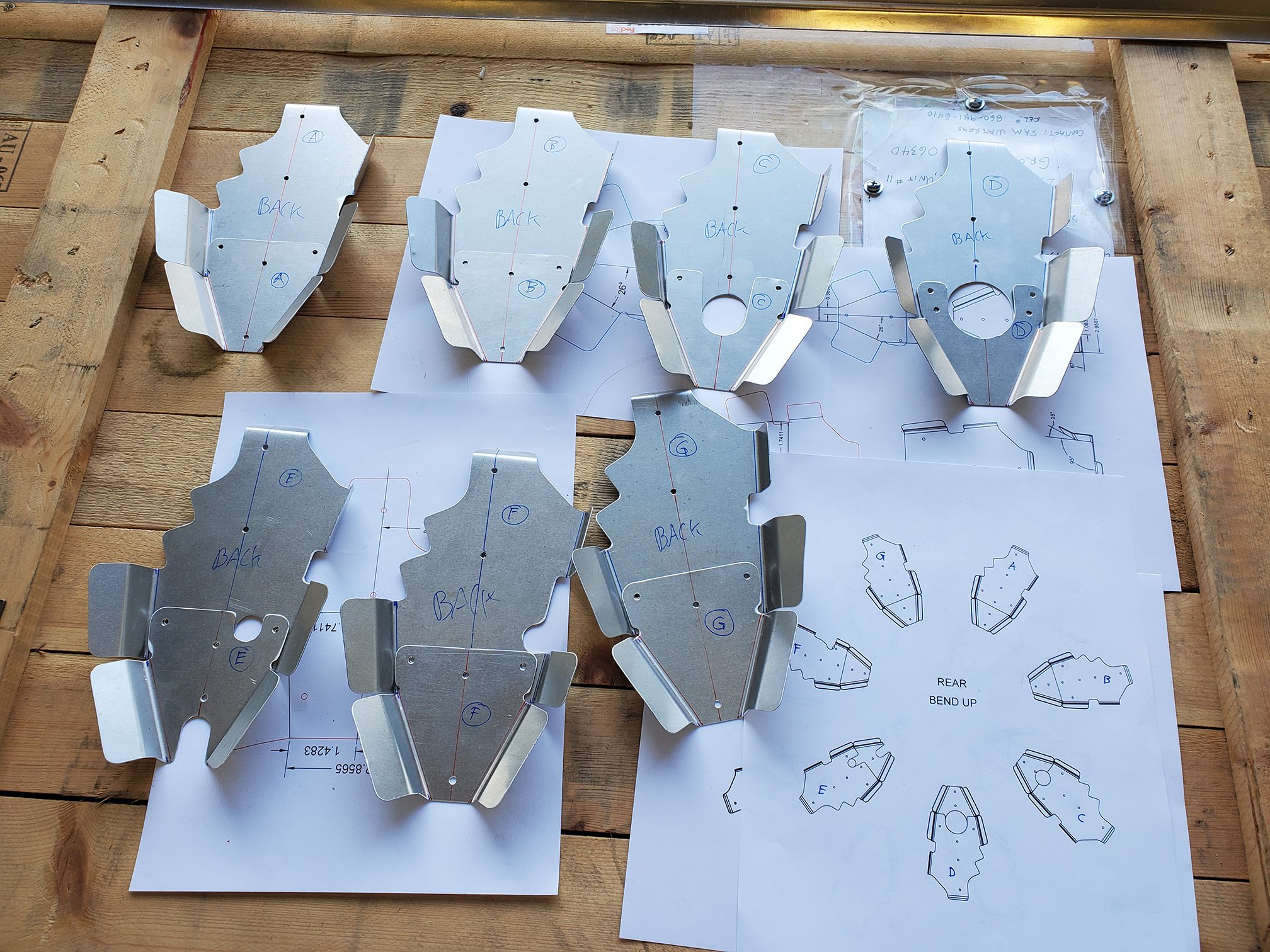

I am modeling the split flaps and actuation assembly. The flaps and wing mods are designed. Still working on the actuation. I have an electric flap motor that Im thinking of using, but my engineers want me to put in a manual flap handle. One less thing to fail at the wrong time - although I’ve never had electric flaps fail on me in my Cessna and Grumman flying career. Trying to find the space for it between the seat and side wall - as it wasn’t there when we put other stuff in place. Manual flaps are fun - flown with them in Cherokee’s. They are great for feedback and quick action. Flap position indication is intuitive as well and less parts. Gonna try to make that work. Either way, almost ready to start cutting sheet metal. Yah!

Elliot Seguin said he would be available in the Spring to help us out. We still have the stall and envelope expansion flight testing to do. I want to do the next flights after the mods to make sure we iron out all the issues so Elliot doesn’t have to. Way more productive to have him flying those test cards and not managing temps, pressures and stuff. More productive is more cost effective too!

We have elected to skip Sun and Fun 2023. First, we will be in the middle of flight testing and that is top priority. Getting all the test results as soon as possible helps get the Beta airframe design finalized. Second, because of the modifications, we don’t have the three to four weeks we loose by going to a show. It does take that long as the show is a full week. Sorry to all our fans that go to SNF. I love SNF and we will be there for sure in 24. Might fly down for a day or two as a tourist. Oshkosh will be our show priority for this year. We want the Beta tail kits ready asap and before Oshkosh. We have to focus on finalizing the design. With the P-36 flying, we can likely visit other regional shows after the big one.

One of the big comments we hear every year is “can you fire it up - want to hear it run”. That is a very large drawback to the Homebuilt area booths, they don’t allow any engine runs or aircraft movement during show hours. So we have decided to change our booth location for Air Venture 2023. This year, we will be in the Ultralight area. A mixed blessing/curse. There is way less foot traffic during the show. The booth spaces are larger which helps a lot. The big benefit though is we can run the engine and possibly fly the plane if we can get her in and out of the short strip. I know she can take off fine from there. She gets off quick and climbs right out. So far, my landings are too long. The flaps should help a lot. I do think we can figure out how to land her in much shorter runways once we know the stall behavior better. It will mean a lot of practice at a similar flying field - I don’t mind! Back-up plan is to push her across the fence line and run the engine. Just hearing the engine roar to life will sell engines. Seeing the P-36 buzzing around will generate all kinds of interest!

Will wrap this up here. Planning to write a Holiday entry and project update before Christmas. See you then.