Time Marches On

Hello once again. Been a while, a lot of stuff going on. We are test flying the prototype and finally have all the bugs worked-out. After multiples of flights with cylinder head and oil temperatures soaring into the red before trying to cool it down, we have managed to fabricate and install a set of cylinder head baffles that are working well. YES! This has changed the machine into a fun flying sport-plane. I’m getting long flights and chewing away at my 40 hour phase 1 test period. We are at 25 hrs as I write this on a very chilly Sunday morning. We are really feeling the time pressure as winter is setting in here in CT and I need to get her out of phase 1 before it does.

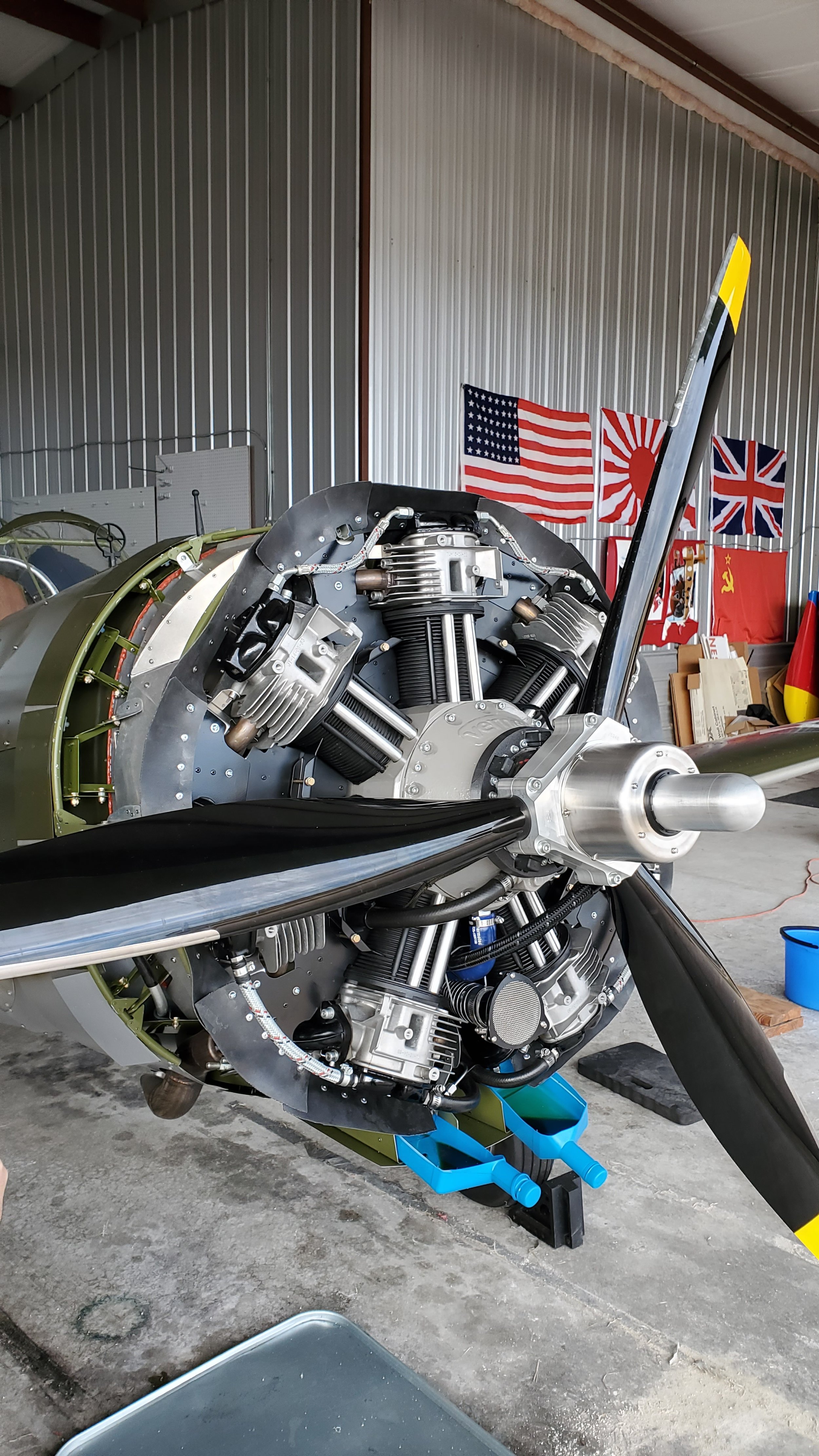

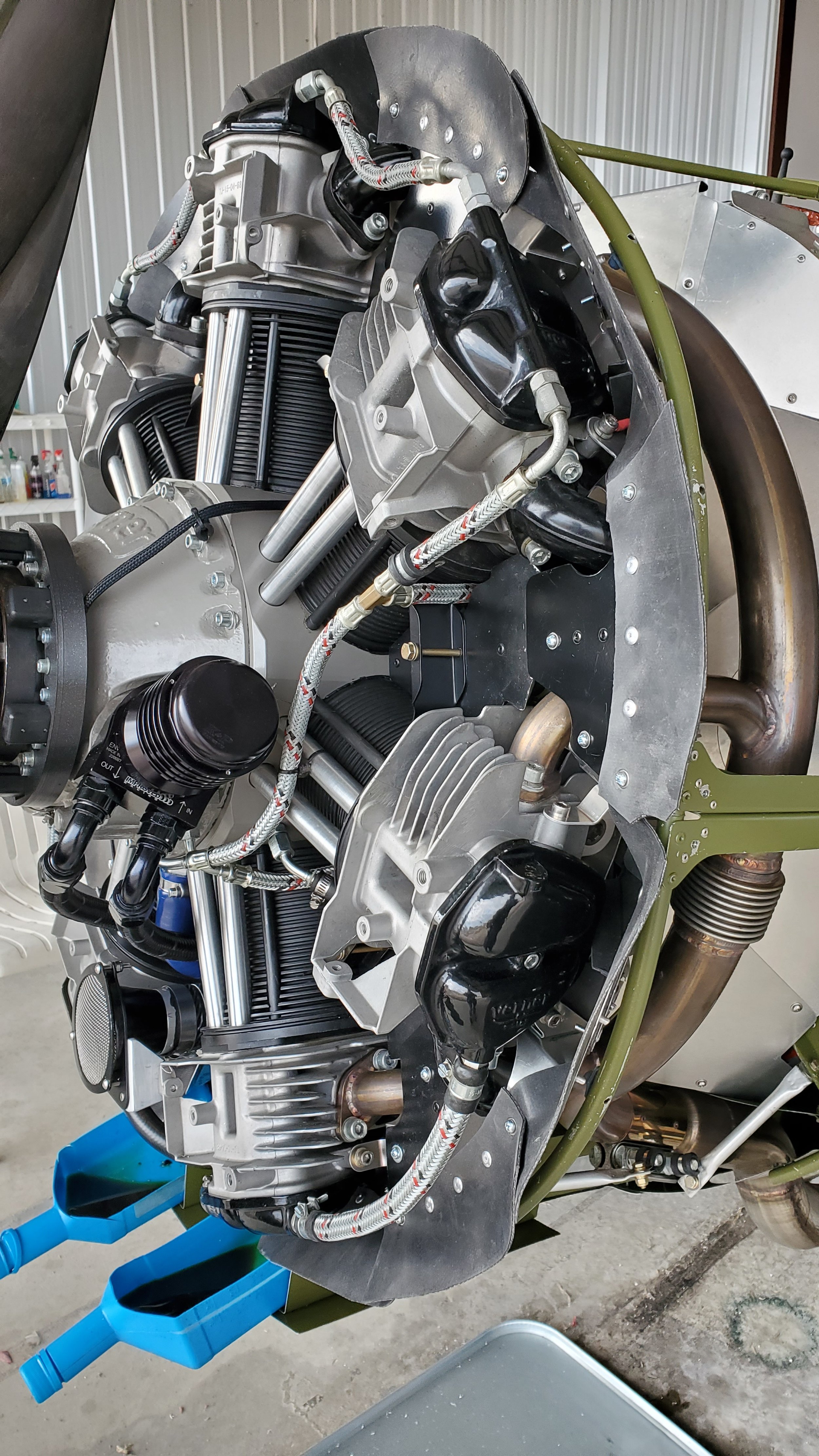

Concurrently with Brian Kelly of Radial Conversions, we have developed a cylinder head baffle set for our 7U installation. Brian has a 9S on his RV-8R. He made a composite one-piece baffle between each set of cylinders. Ours is multiple aluminum pieces and baffle material that we added to our inter-cylinder baffles we had already installed. Kind-of a little getto or hodge-podge, but in the end it is working as planned. Some say it looks professional – I don’t know about that. Lots of lessons learned and changes we can make to a less piece-meal version for kit production later. We like the one-piece version that Brian is doing and might work in that direction. However, with our cowling support frame and other things in the way, it was not possible to do it like that. Ours is 7 parts formed into 4 assemblies between each cylinder. I think we can get that down to three in aluminum. One thing we have going is ours can be removed and installed without removing anything from the engine.

How is the flying going? Im having a ball! I’m getting used to landings and approaches, different runways and crosswinds. I’ve done stalls and manuvers and opened the canopy in flight. It doesn’t mind one bit, but does slow it down about 4 mph and causes a trim change when mostly open. Stalls are benign, flies again with easing of the back pressure. Stalls power off and clean at 60mph, 20 degrees of flaps is 55mph. Will get you the full flap stall speed and then try power on stalls. I can climb to altitude now, although anything more than 3000 ft requires a step for cool down. These Verner engines heat up and cool down very quickly. Not a problem, just something to plan on and operate with. Flying around I am chugging along typically at 2000 rpm with the temps solidly in the green at 105 indicated. Will be getting a BOM to calibrate with. Observers on the ground are saying it is moving right along and sounding awesome with the radial rumbling. Looking every bit the part of a WW2 fighter plane. I used a GoPro strapped to my forehead for one flight and got some awesome POV video. Having looked at a few POV videos of Hurricanes, SpitFires and P-40’s, you get the same sensation! I’m in a fighter plane! I love seeing the star roundel out on each wing! Will post some videos very soon.

This plane is very responsive to control inputs, so you have to fly it the whole time. I can trim it to level flight but the normally choppy air this time of year makes that difficult. I am also using some right rudder to keep the ball centered and that means we need to design the next machine with some offset for the vertical and the engine mount. This one is straight for both. She rolls super quick and makes very tight turns about-a-point. I have not done aerobatics yet or high-speed dives. That will be coming. I want to really get used to the plane and get some good video and images before doing anything very risky. If we have to bail, it will be a while before the next airframe is flyable. I’m not super worried – she has great flight characteristics and responds so well to everything – it’s just a due diligence thing.

This prototype is very fun to fly, but now we know what we need to do to improve this design. Some design changes we have known we wanted to do and some are new ones based on flight data that we needed to get. The big ones are: Weight reduction, slightly more longitudinal and roll stability, more power, more fuel capacity, faster cruise and top speeds. We have a plan to incorporate all of these and are working on changes to the 3D model. The next airframes are going to be a blast to fly and exactly what you are expecting the plane to be. It’s almost good enough now, but the changes we are doing will really help it to be a success. Everybody wants more speed and power, so we will adjust the cowling to accept the Verner Motor 9S 158 hp radial engine. The P-40 will be able to handle up to a small V6 powerplant, but for sure a 140 to 160 hp Auto Conversion or Rotax 915/916 or Edge Performance mill. This will make for a really powerful aircraft – a far leap from the Lightsport initial concept. However, Lightsport is changing and we need to change with it. The Mosaic rules will allow for higher hp, speeds, retracts, props and the stuff we all want on a scale fighter plane. We don’t want to make a plane that is amazing, but dangerous. Instead, we will limit the power to reasonable and keep the low stall speed and good habits.

Vans Aircraft sells “total performance”, which is very accurate, and we applaud them – can’t beat them at all. They have a very sleek shape and are optimized for what they are. What we are finding is that the older WW2 shaped machines are just draggy and need power to go fast. The P-51 and some other late war designs are quicker machines due to laminar flow airfoils and other refinements. With limited space in a scale replica, we need to get as much power as we can to fly at expected speeds. We also can’t just throw in a V8 with 500 hp. That changes the whole scope of the project and kit. That would likely double the cost of the finished machine. That is because you need a proper propeller and psru unit, and a fully engineered engine installation. It becomes a really hard project and one that few builders complete on their own. Some builders are paying big money to get their high-power installations done at a shop. That is not a typical Sonex or RV type of project. Look at the Titan and Stewart installations. Incredible, but big bucks and time consuming. We are trying to make a more buildable and affordable project that is just as fun when all is said and done.

What makes a replica fighter aircraft fun? Good question. Likely it is a different answer depending on who is building/flying it. For some it is the power and speed of a fighter aircraft over the typical GA sedan-like airplane. Others might think that it is maneuverability and acro. Some just love the shape of their favorite warbird and want the feeling of being in one. None are wrong – that is all a big part of a replica fighter experience and aura. We would add that it’s the mission that makes it fun. It’s fun enough to fly a sporty aircraft around – by yourself. The typical high dollar replica fighter is rarely flying with another. ScaleBirds mission is to make more replicas that are affordable to where there are plenty around and groups of them can meet up and fly missions together. We are thinking that top speed is not as fun as flying with other fighters on missions. Even if it is loose formation or chasing each other. Look at the Vans RV flyers, they are usually meeting up with other RV’ers and flying to get their burgers as a group. The camaraderie is the most fun part. Sharing the experience. That is what we want to bring to the replica experience. It can only be realized with larger numbers of replicas flying.

Numerous things have been slowing us down, mostly me. Since the last update, I had gotten a tough head and chest cold as well as had to visit a good friend who had an injury. Then the baffles took three weeks – way longer to make and install than I figured (always the case). Time does not slow down though, and we are feeling it. Weird stuff is happening with the economy and the world – even Van’s Aircraft is having capital issues. We are hanging tough and trying to keep focused.

Our primary goal is completing our flight testing and get past Phase 1 restrictions before the winter gets serious. This is so we can fly the prototype to Florida in late March 24 to get ready for Sun N Fun. Secondly and right behind the first goal is to get the redesign of the kit completed for the beta builders. We are pushing for a Christmas/January delivery for the tail kits. A few engineering calculations are required and then the cad and cutting of parts will be very quickly done. Hopefully the calcs will be done by early December. We will be building our own new airframe concurrently with our beta builders. I keep looking at improvements to make to this prototype, but we have to stop working on it. At this point, it is what it is. We have to get on to the next improved airframe and get kits into production. Time is marching on!