Two Thumbs Up!

Hey there. ScaleBirds has resumed flight testing the P-36 Hawk prototype! We have two flights on her from this second round of flight testing and initial indications are that the flaps and landing gear mods are working as planned. Two thumbs up! The engine baffles are still not perfect. We are now working on adding new baffles around the cylinder heads to get our CHT temps down. Without them, she is getting hot at the higher rpms - anything above 1800rpm she just gets hot real quick. So as soon as we can tame that, we can proceed to higher altitudes and get to higher speeds and dive testing.

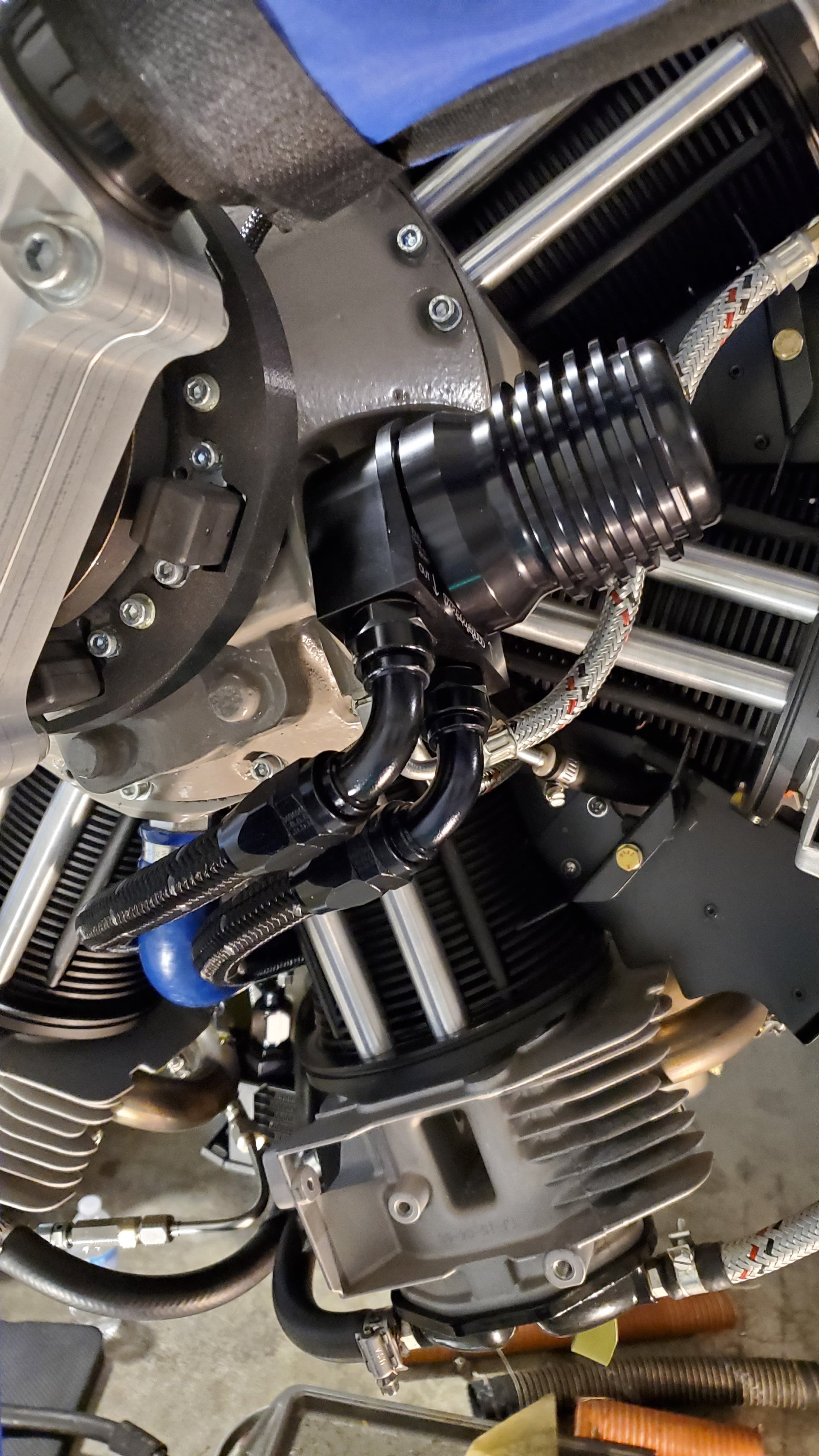

We incorporated split type flaps - very similar to the original Curtiss P-36/40 configuration. These are electrically driven by a single worm-gear electric actuator mounted behind the seat. We created a mechanical flap indicator gage and installed that. Moved the pitot static ports and incorporated tail lifting points similar to the real aircraft. We modified the landing gear to have oleo struts. Then changed the oil cooler and mounting for better air flow. We added a remote oil cooler adapter and a cleanable oil filter for better oil pressure and cooling. We had inspected the engine crankshaft and propeller hub after the propeller tip strike and test ran the engine many times. Added a new propeller and had to pitch it. We did that and did pull testing to get thrust at several pitches.

After we finished with all the mods, we had to prep for flight and also do a weight and balance. We came out 4 pounds lighter overall. So that told us the landing gear legs are a lot lighter which makes a lot of sense - those springs and other parts were heavy. Then some delays hit the schedule. Covid ravaged the family. I got it last after a week of looking like a deer in the headlights. Everyone of us got it, but it never got dangerous. Like the flue but different too. After getting over that, we were ready to fly, but the headaches wouldn’t quit. I was dealing with it for a week and a half - during some amazing weather for flying! Finally felt good enough and we had a beautiful afternoon - it was time.

The first flight was about an hour and was circling the airport the whole time, trying to get to altitude. She was slow and at wide open throttle was well over red-line and indicating 110mph. The propeller needed more pitch. Unfortunately, I could climb to pattern and then had to fly around letting the engine cool down. I then could gain about 500 ft at a time and had to level off and cruise around the pattern cooling it down. I had time to play with the ailerons and tail effectiveness. Very effective! I finally got her up to 3500 ft and decided against doing stalls, but did do slow flight and tried the flaps from 0 to 30 degrees. I didn’t want to tempt fate with full flaps. The tests were a success! 10 degrees was a very slight trim change and a couple MPH lower. I could readily maintain 85 mph on a little power. Then 20 degrees or two notches it slowed about 5 mph and a little bit more trim change. I could maintain 80 no problem - again I was not intending to stall it, just get a feel for how effective they were. Three notches got me readily down to 75 and maintaining altitude with a bit more power to overcome the drag - not much of a trim change though. Calling that a success, I brought it in for an approach pass and found that three notches was a good approach, requiring a little power to maintain a good decent rate. I found that if I reduce power to idle and she still drops like a rock. The flaps really help a lot with visual of the runway and enough drag to keep the prop at an rpm where it isn’t a huge flat disc of drag. Very much more controllable now. I brought her around and did a long, curving base and final like the WW2 fighters do and landed with just the slightest bounce in a three point landing. The oleo legs worked perfectly and I was happy as a clam.

The second flight was delayed due to TS Lee and out of town obligations. Took the time to re-pitch the propeller to get more speed and better cooling. For the next flight, kept it short and sweet at just pattern altitude to see if we were flying faster at a better rpm and to get some video of the flaps and landing gear working. So the first flight was so long with a couple high-speed taxis prior to flying that the GoPro cameras both ran out of battery and we didn’t get the shots of the flap testing or the landing. So the goal was to get that footage and also try full flaps. Did a high-speed fly-by and fast downwind leg indicating about 125mph - GPS data from the GoPros showed average of 130 to 135mph with wide open throttle of 2300 rpm. Red-line is 2380 for three minutes so maybe a smidge less pitch is required. Then I slowed her up and tried the flaps - starting with opening to 10 degrees at 100 mph - a little faster deployment speed than last flight and it did it just fine. Then two and three notches on base leg - allowed her to see 95mph and no issues - so the flaps and actuator are strong enough to handle the normal air speeds. Turned final and added full flaps at still a ways out. She slowed up quick and I had to add some power to shallow the decent rate. I could see the runway real well and she was stable around 75 mph. I flew her on and touched down in almost three point, but she skipped and skipped again a few times I think. Finally settled-on at around 50 mph indicated. It just wanted to keep flying! So I think I can get used to full flap landings, but likely three notches (around 32 degrees) is smoothest so far.

We found an oil leak from the bottom of the cowling and decided to pull the cowling and investigate. Indications are that the valve covers were not very tight and speculate that the lower ones were filling up with oil and dripping past their o-ring perimeter. Tightened them all up and checked intake and exhaust bolts. Some needed tightening. Thermal cycles were likely causing them to loosen. We then ran the engine with no visible oil leaks so we are ready again. Will try to get the baffles installed this weekend while it’s raining from TS Ophelia. Then it’s time to get at those test cards and get her through phase 1 flight testing.