Getting There

Howdy folks! Sorry for the long pause. We went to Sun N Fun and what a week! Always fun and warmer than here in CT. Everything worked out great for the show. Steve Wolfs’ P-47D project was a huge hit! We could have sold 15 of them for real if we had a kit. More on that later. Terry Allred allowed us to display his 3 cylinder Verner Motor in the booth as well. I hope we will see a number of sales from the effort and that is the whole reason for going this year. We want to help Verner Motor keep busy building engines. In addition to the engine focus of our trip, we managed to re-kindle some old contacts we had and build some new relationships. Networking in a small industry. We have our work cut-out for us getting into the kit production phase. One of those relationships is with a kit industry big name. He knows the Verner family very well and is interested in helping us transform to production. Can’t get any better. He also is very experienced with getting ASTM certification for SLSA aircraft. We will see where we can go with that.

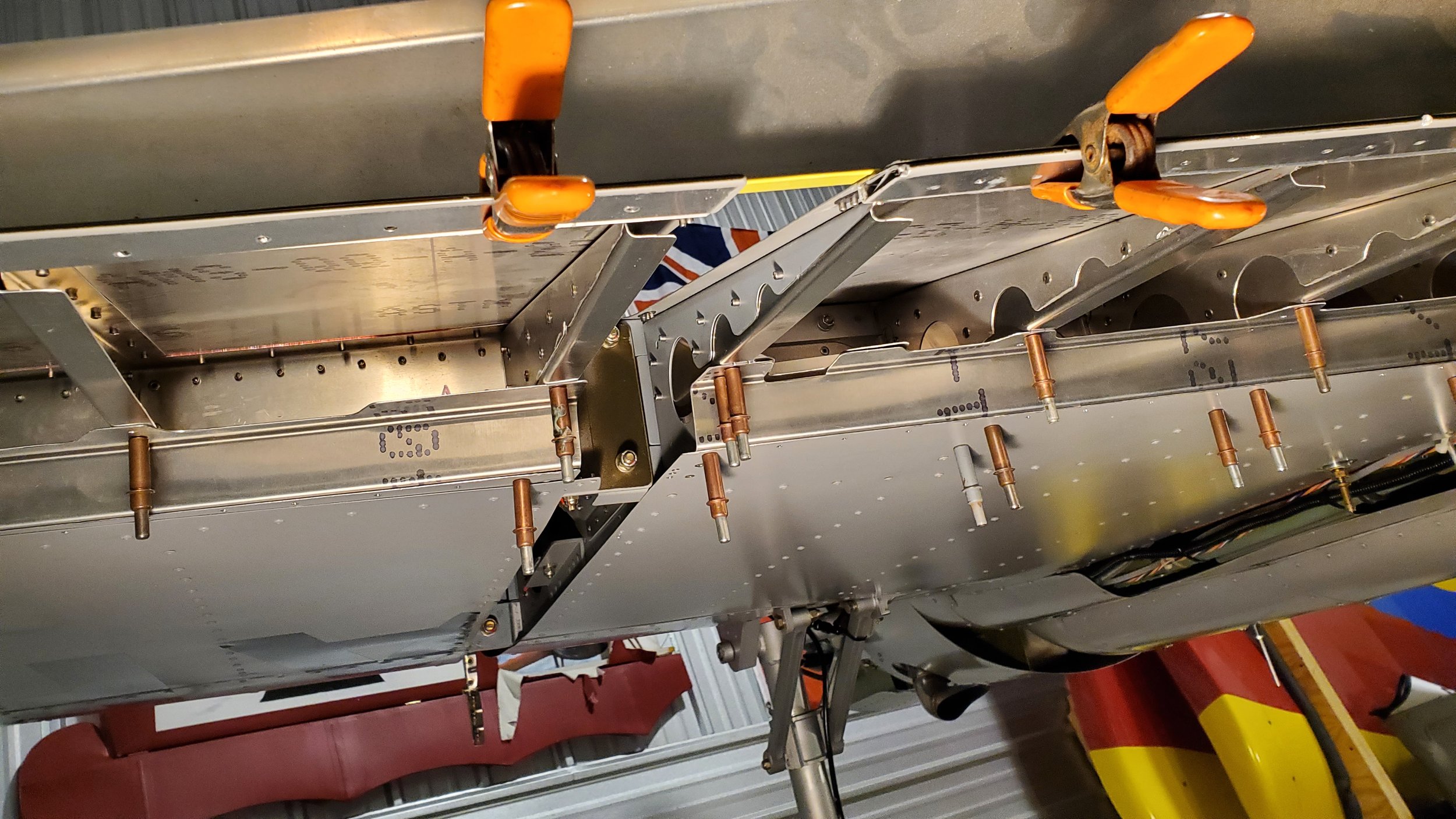

Steve Wolf is progressing very nicely on the P-47D replica. It will be a huge hit when it is flying. Jim Busha the marketing VP for EAA stopped by and wants to stay in touch with the progress - Sport Aviation feature article coming! The 47 features fully functioning cowl flaps, sliding canopy, actual 47 throttle quadrant, gun sight and stick grip. It has the turbo exhaust and inlets in the rear fuselage. Fully retractable landing gear - tail and mains. Will have guns, drop tank and bomb racks. The Verner 9S fits nicely in the cowling and with an adjustable prop will give it a great sound and good thrust. Steve is amazing with sheet metal fabrication - despite being a rag and tube aircraft builder mostly. He is having fun re-learning his metal skills. The finish is first rate and the plane looks like a production version. Amazing!

After Sun N Fun, I took a week off. I was exhausted and felt like a zombie. Maybe a bit too much heat down there. Finally started feeling normal and got back to work on the P-36. Finished up the modifications to the trailing edge ribs and added the flap spar sections after installing nut plates for mounting the drive tube hinge blocks. Each side of the wing gets four of these blocks. This last week we test fit the flaps after riveting up the flap spars - we could not test fit them while we had a bunch of clecos in the way. Found that our flap ribs were a smidge to high to nest clear of the torque tube. So we modified the fwd inch of each rib to clear. We will incorporate lessons learned in the kit flap design and they will fit up much better. The Devil is in the details! Sometimes, its just a discrepancy between the cad model shape and the actual shape after bending and then riveting parts together. Production parts would be much closer to the cad shape as rivet holes and forming jigs would be better located and repeatable. Anyway, the flaps should be installed this week and then the drive system over the following week.

After the flaps get done, we will tackle the landing gear legs. Scott has an important job to get done over the next couple weeks and then a planned trip. AFter that, we will get the landing gear leg parts completed in quick order. So I have some time to get the flaps done and then mount and adjust the propellers. We are also making cylinder head baffles to try to help with additional cooling of the heads. We may have to modify the cowl inlet shape to allow more air to move outwards to the cylinder heads with less restriction. Another lesson learned. When installing a full cowl on the Verner, allow as much distance in front of the cylinder heads as possible. We kept it fairly tight - maybe 2.5 inches from the nose bowl to the front of the heads. Steve Wolf has about 4 inches on the Samson Mite and has no cooling issues at all. Moving our cowling at this point is not easy and would likely require a whole new cowling and frame. We really want to spend the time on the next airframe if possible.

So we are getting there. Slower than anticipated and some of that is even though we didn’t have to bring the plane down to show at SNF, it still took time away from the project that we don’t get back. I was thinking we would only be about a week away from the effort, but it actually was still three weeks off from working it. We used about a week before leaving getting everything together, making new signage and printing brochures, etc… I didn’t anticipate being worn-out for a week after the show. So we are quickly running out of calender before AirVenture. We are working as hard as conditions allow. Back to work!