Keeping At It!

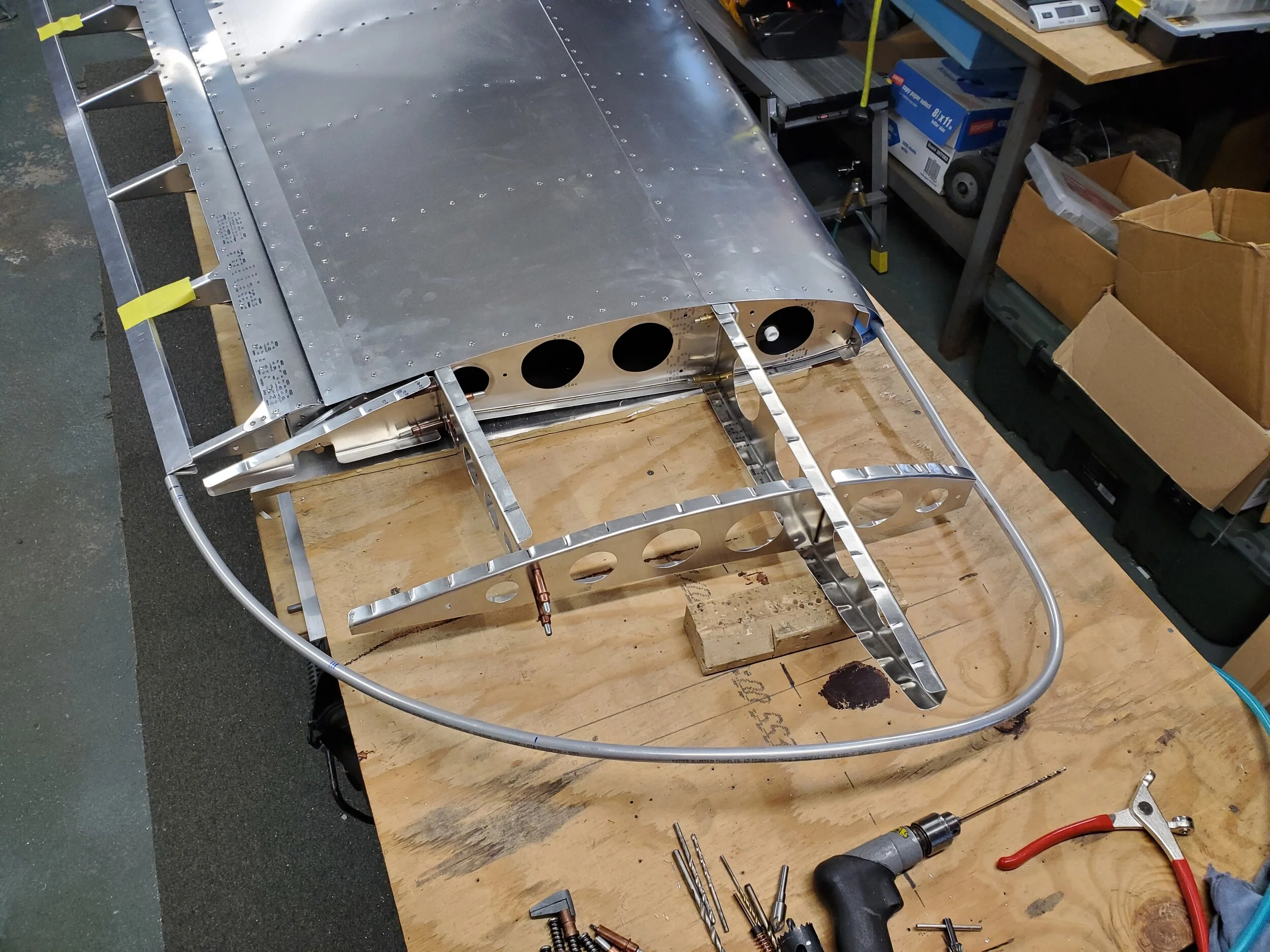

Greetings! Ok, so I am thrilled to report that we have the wing center-section installed and landing gear is down and locked. Fantastic! That bit of work took all of the weekend of the 16th, 17th (yes, I did get the bolts that Friday). Including a very late Sunday night work party. We got a little punchy, but had fun too, notice the image where Scott was trying on the Flinstone style landing gear! I want to thank all our crew for helping out and getting that done. Well done! This pushed us past our road block and allows us to progress on all systems and components. As evidence, this last week and weekend was a beehive of effort. Here is a short list of items we touched:

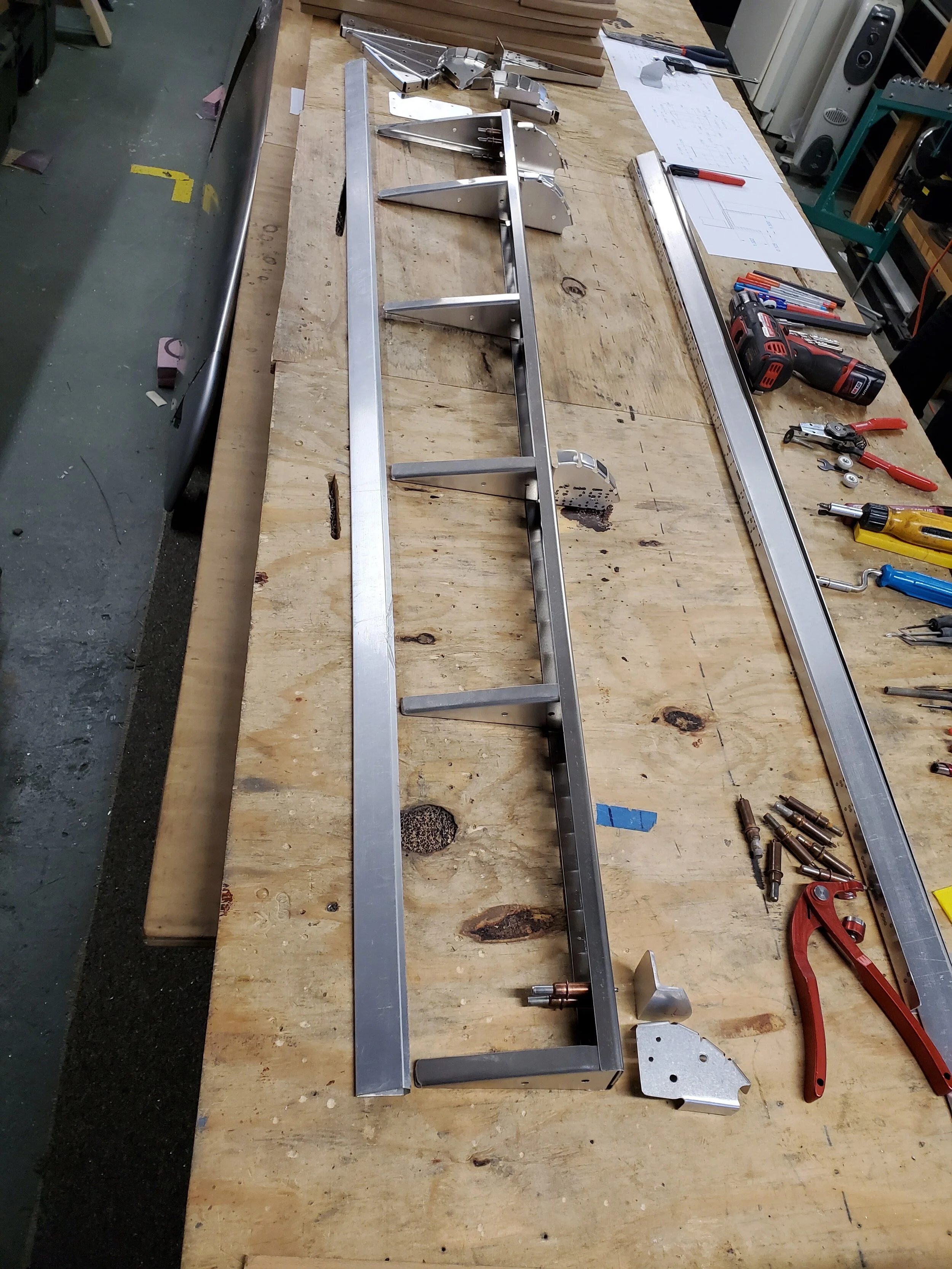

Completed the fuel vent lines and they are final. Installed Curtiss drains in the fuel tanks. Installed the seat harness after reinforcing the aft spar attachment brackets. Completed the pitot and static hose runs and connected to the instruments. Installed the oil tank. Adjusted the location of the fake 50 cal guns. Final fitment and adjustments to the tail wheel strut. Final install of the rudder cables and turnbuckles. Fixed the left main gear leg scissors - they had sloppy bushing holes and allowed too much movement of the tire. That job required us to remove the lower strut cylinder and machine new holes for larger bushings and bolts. That is complete and much better - though not perfect. Taxi testing will determine if we need to attack this again. We started to install the control stick assembly and hit a snag. The new larger bolts in the spar splice plates are too close to the mounting bolts for the stick assembly. We are designing a new mounting installation and will be fabricating that right away. We determined to add fiber-frax material aft of the firewall up to the first bulkhead - an issue we have been contemplating for a while. After we add that, we can close up the lower firewall with the bottom cowl components this week.

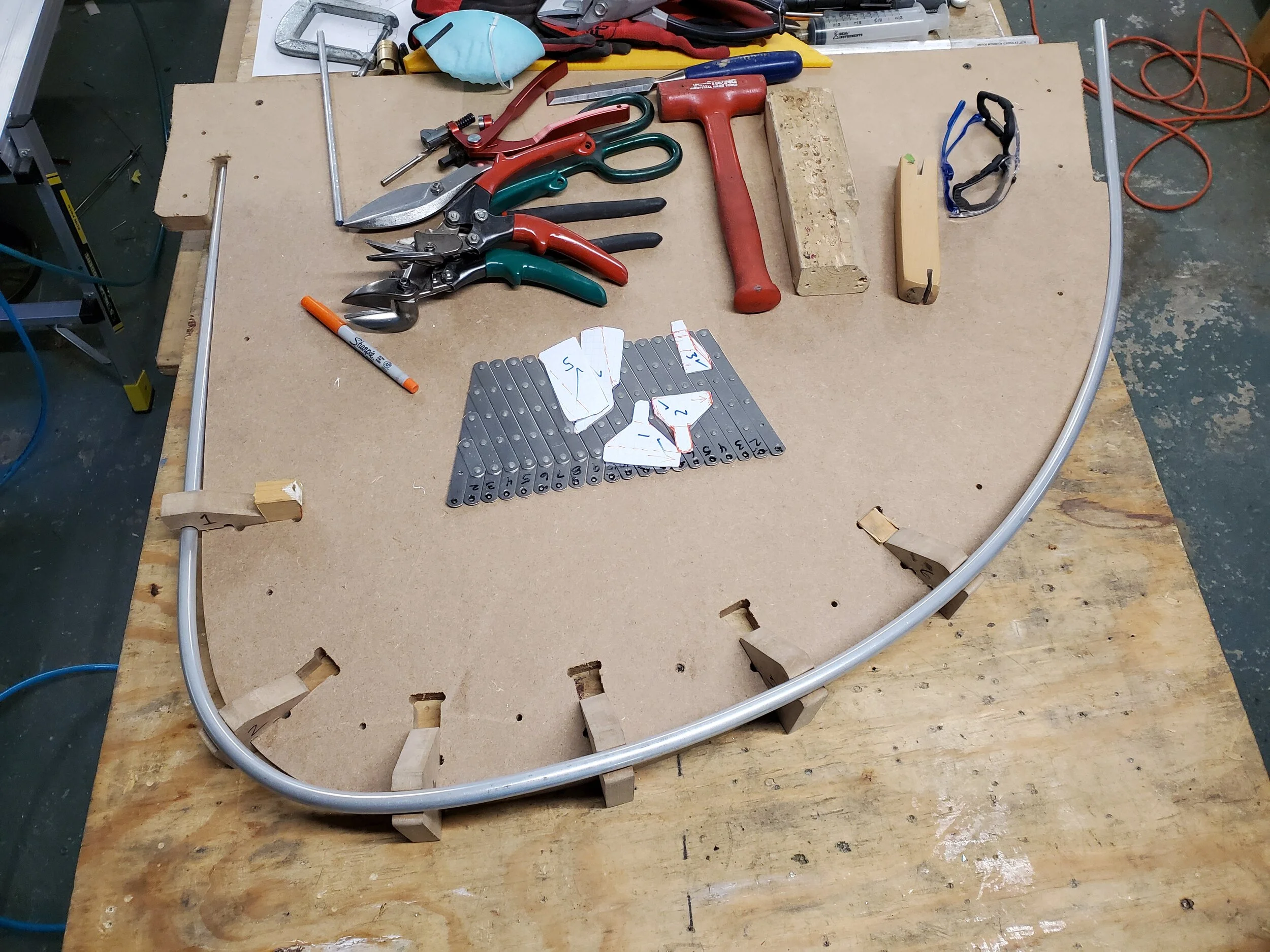

Been trying to decide what to do for the canopy latch. Images of the early model P-40 latches showed a weird base for the crank handle. After accidentally seeing one similar in an internet search for latches and hand cranks, I realized that Curtiss had used an accessory hand crank handle from a Singer sewing machine. The old hand crank they would use instead of foot operation and as a quick bolt-on accessory for doing bobbins (according to my daughter). I’m guessing this drove the chain drive for the canopy with a 3:1 gear ratio. So, I purchased one of these on-line and will go about modifying it and making new housing and cover plates with the idea of making a latch for the canopy, not a full-blown crank-it-open chain-drive like the original had. This is a simpler and lighter canopy.

This week we will finish installing the control column, begin the fuel delivery system, install the lower cowl and cooling tunnel, locate firewall components, battery box, install the tailwheel control cables, and the elevator control push tube installation.

She is starting to look like an airplane and looking good too! Can’t wait! Keeping at it! Click on the pic to see the next one.