The Twist

Spring is trying to break through here in the Northeast, but not quite able to shake that winter chill. April just arrived and we have been working all of March on prepping for a new engine. Foremost was dealing with our landing gear. The third time I believe. This time, we had a nagging toe-in twist when the full weight of the aircraft was put to them. Studying it carefully, it was a combination of two things. The teflon liners inside the main tube had been relieved to allow the gear to easily slide with the spring motion. Well, we had given it too much clearance and that allowed the whole lower leg to pivot off center slightly. That little amount of sloppiness exacerbated the little bit of miss-alignment that I had welded-in on the scissor-links. Allowing the wheels to still toe-in a little bit. Barely noticable, but I don’t like it. One side slightly more than the other as well. Dang it!

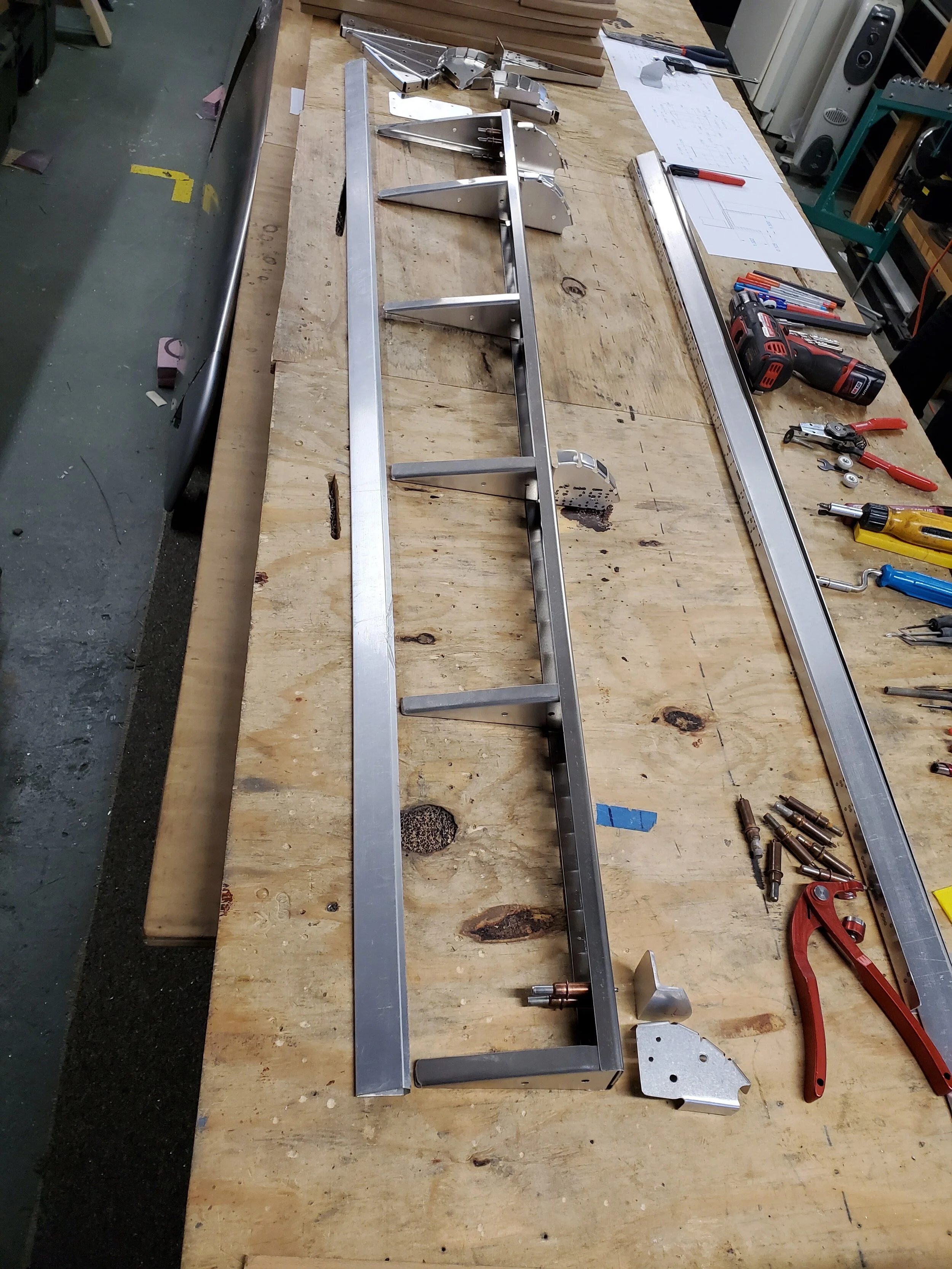

After removing the engine to crate it for shipping to it’s new owner, we put the A frame back onto the engine mount and removed the landing gear. Scott studied the issue with the sleeves and ordered new teflon tubes. They arrived and were undersized on the ID. He then created a special reamer to take out the .010” all-around needed for the lower leg shaft to slide inside smoothly with no binding. The front of the reamer is the same as the id on the existing tube. Then he tapered out to the final ID we want and added cutting flutes. It worked, but clogged with chips quickly. Modifying this to allow the chips to exit also messed up the surface finish. Made a second reamer more like the original but shorter. This did a great job. It did take some time and careful drill work. We are just about done with the landing gear - again. We will be doing some careful milling and drilling of the scissor link upper mounting lugs to get them to track the wheels better. A little milling, a little paint, makes her what she aint. I am planning to get that done this first weekend in April in order to be able to put the gear back on and remove the A frame.

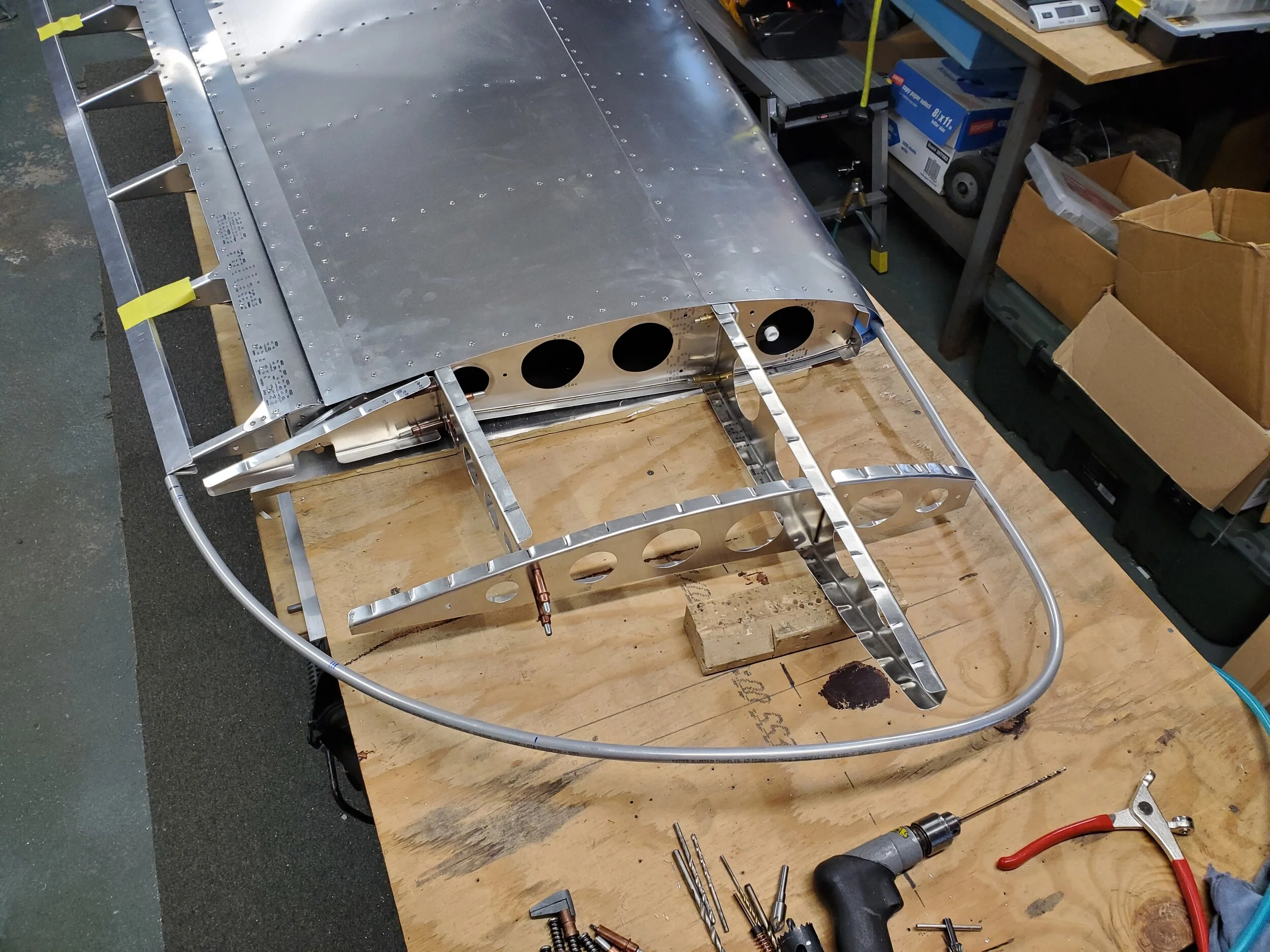

At the same time of working on the landing gear, we have been fabricating the fuel pumps panel assembly and installing it and the rest of the fuel hoses and tubing in the fuselage. It is 99% complete from firewall to the fuel tanks. Just one little thing left - adding the low point drain. That will be doable after we get the landing gear on and install the bottom skin and tunnel. Then, I can work from above the seat and below. Its a sequence thing.

Also have been working on the electrical system. Installing wiring and loom for fuel senders, landing and navigation lights. Made plywood mounting panel for the battery, solenoids and terminal blocks. They will fit up in the gun deck between the machine guns and on top of the forward fuselage frame bracing. I am finishing up the electrical schematic to know just how many switches and circuit breakers we will need a home for.

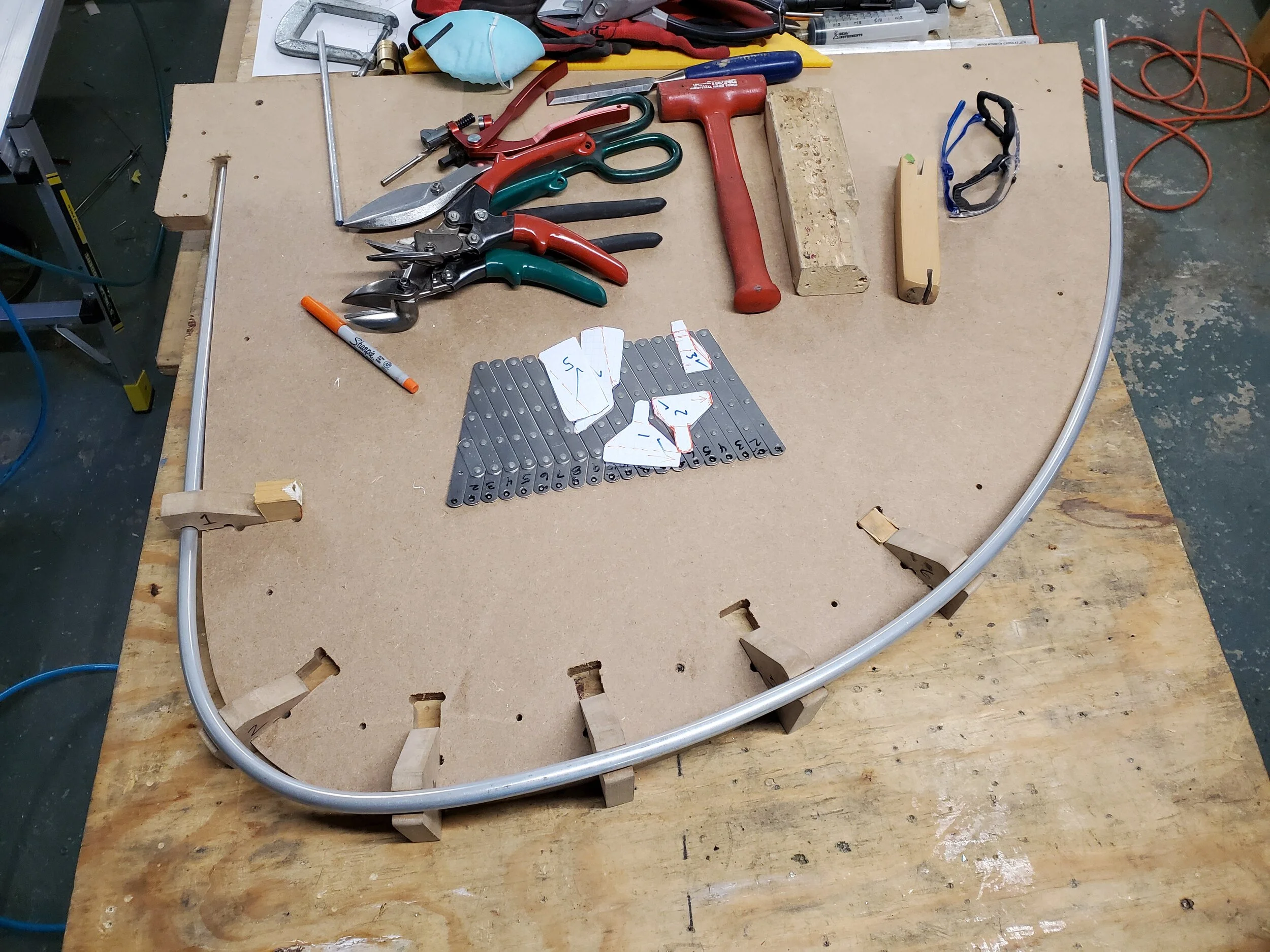

One more thing we have been working on is the tail and wing fairings. We had Jack Charles of Madison, WI English wheel our fairings for us. He was eager to try it - being a metal smith shop teacher for a high school and technical college. We sent him templates and descriptions of how much to roll and where. They came out very well. Excellent for only written descriptions and images. That is a tough thing to do and he did great! I trimmed and located the fiberglass trailing edge of the wing root fairings, drilling them when just where I wanted them. That plastic exterior painters tape did great for holding everything in place. The sheet metal fairing panels were then taped into location and adjusted as necessary. When good, I drilled and cleco’ed them to the wing and fuselage.

I used what seemed like a bunch of clecos to do it. I was kind of disgusted with my work thinking I had too tight of hole spacing, until I looked back at the reference photos. Curtiss had done the same thing on the real P-36. Lots of screws in the fairings and so ours looks right after-all. Back when we made the large trailing edge fiberglass pieces, we had made small fiberglass fairings for the leading edge of the wing where it gets seriously compound and tight. These were not the right shape after installing the sheetmetal fairing panels. The leading edge of the tail surfaces is another very tricky spot and we did not make a fiberglass piece for that. Thought about it long and hard and I want to try to pound out a soft annealed sheet metal leading edge. Ordered plenty of soft sheet and am about to get on that project. Getting those pieces done will allow me to finish the bottom section of the wing root fairings. Shouldn’t take too long. Adding the wing root fairings makes it look so much better! I can’t wait to paint them and see it with the wings and cowl.

Oh yah, Rob Walty made us our four quadrant cowling side panels and the nose bowl. We will be ready to start working on the cowl shortly. April and May will be really fun work!

We will be at Sun N Fun 2021 in a couple weeks. Our booth is in front of Building A and B along the main thoroughfare. Look up N68 on the exhibitor map. Sorry, we will not have the plane there. Way too close to flying to dismantle it and risk the trailer rash of hauling it both ways. We will have a brand new Verner Motor 9S radial engine on display. Our customer for that engine, Bob Beaty is #2 at the Sun ‘n Fun organization. He twisted my arm to have it on display. So after not planning to attend, we will. If you are going, please stop by and say hello. Love to talk with you. Then, right back to work right after we get back.