Appreciation

Thanksgiving is a great holiday. Giving thanks and being thankful. Appreciating what you have and what’s been done. Thank you for following us and supporting our efforts along the way. You guys and gals keep us going and inspire us to be better. We appreciate you.

We have a great team and its growing. We have added two Electric Boat engineers to the team since Oshkosh. Stuart and Shin. Stuart is from Michigan and mechanical engineer - vibration and resonance specialist. Worked in the auto industry and now in the submarine world is a “Signatures” guy. Can’t say anything more about that and not have to kill you. He is starting on flutter calculations for the P-36 and is also starting flight training at our local airport. Trevor met him by happenstance at Oshkosh. He was walking around with an EB t-shirt on. Who does that!?! Shin is from New York and a mechanical and aeronautical engineer. Currently he is a submarine systems engineer providing support for the overhaul and repair group. Shin is helping with calculations and putting the finishing touches on the plane. Eager to jump in and work on the machine and its’ engineering. Thanks guys! Welcome aboard!

The rest of the crew: Aaron, Dave, Gary, Paul, Scott and Trevor (and our spouses and significant others) are helping to push her over the finish line. All are incredibly busy with work, family and life - but find the time. I can’t thank you guys and gals enough! You Rock! Aaron and Paul are finalizing the aero and structural calc’s and checking them. Gary and Trevor are helping me with fitment and installation of components and parts. Dave is supporting our IT systems. Scott is finalizing the CAD models and machining parts. He is also guiding the fitment of some of the important parts. Making sure the lines of the plane are smooth and correct. Attention to detail.

It is getting exciting as the final pieces are getting installed and the calcs are showing we are good. Looking more and more like a fighter! We are also getting more and more people stopping in and checking it out. It is fun to talk about the project and see people react to the concept and efforts. Marketing is one way of putting it. I think several of the locals are interested in buying a kit. I hope so, it will be great to have a local squadron of LiteFighters roaring over-head. It is always good to have a bunch of local supporters anyway and we do!

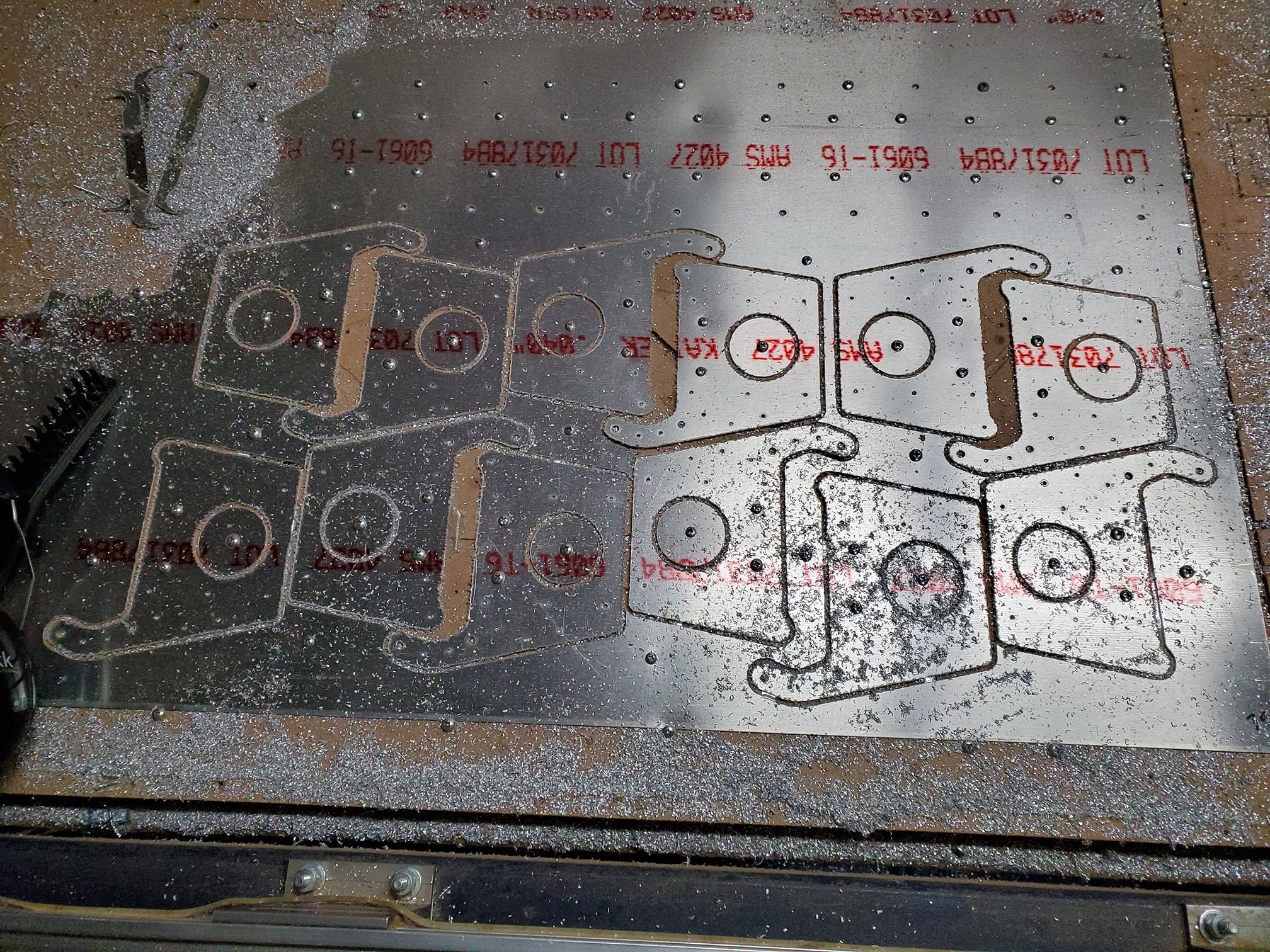

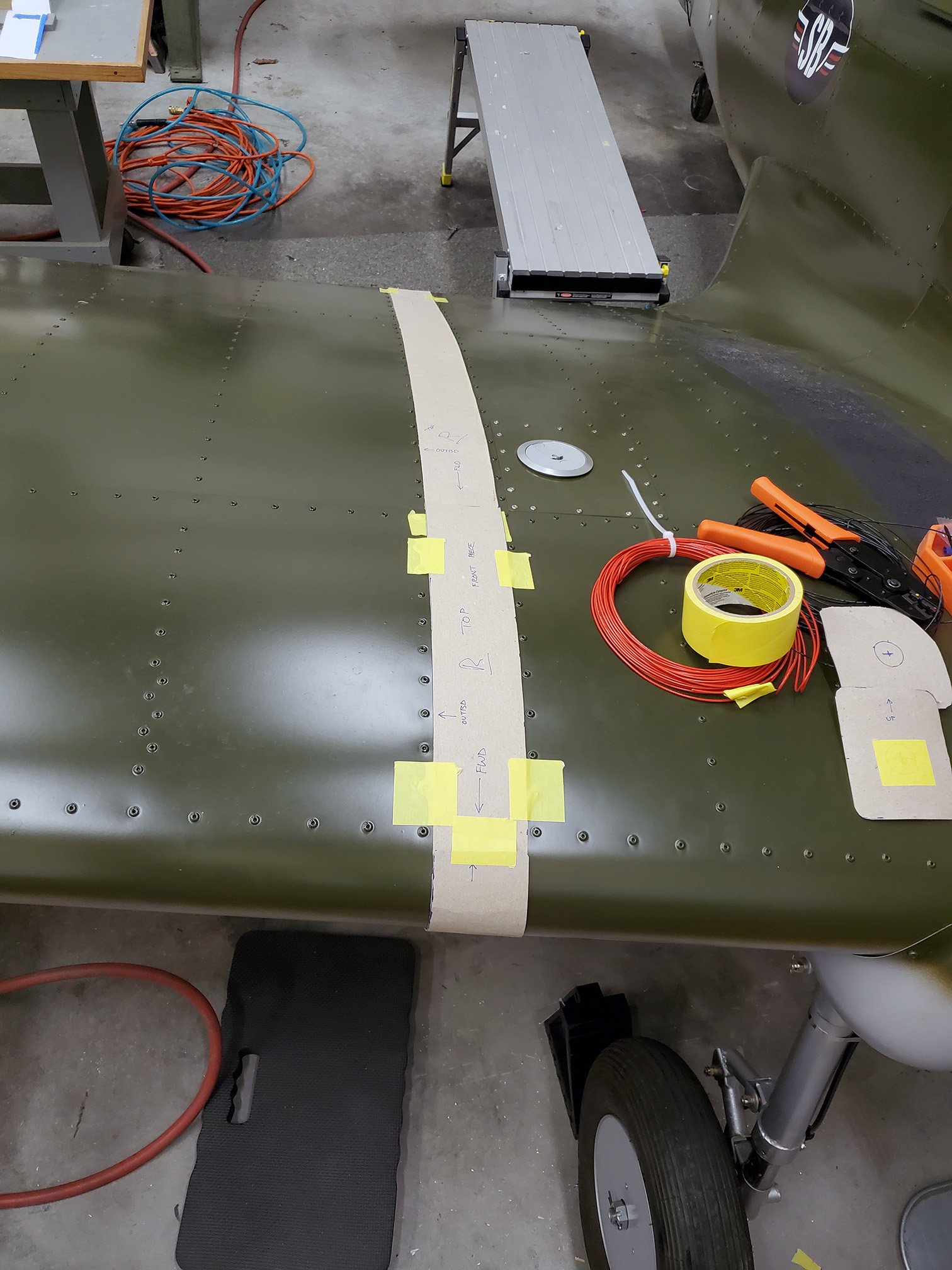

Planning to get a lot done this long weekend. Finalize the gun pod locations on the top cowling, fabricate and fit the wing gap strip fairings, make a map pocket and arm rest, install the fire extinguisher. Charlie is welding a bung onto the lowest exhaust pipe to allow an oil drain. Should be able to get it back this weekend and we will install that pipe and run the drain line. Then we can run the engine again. Next week will be painting all the last parts and installing them : cowl flaps and brackets, gun sights, gun pods, access panels and doubler strips, map pocket and arm rest. The landing gear modification will take up some time in December. While the lower gear legs are being fabricated, we will run the engine, rig and check systems while it is on the old landing gear. Swap out will be quick, then taxi testing.

That’s the plan - reality is the plan always gets changed. So stay tuned and lets see what transpires.

Have a blessed holiday and stay safe!