Now as for the deviation, that isn’t unheard of. And we suspected the pitot system was off ever since Elliot’s maiden flight. From GPS data over time, it seemed to suggest we were about 8 mph off on average. The cause typically will be either the pitot mast head design, or the static port location. One way to rule out the static port is we can drogue a funnel on the end of a 50 ft hose trailing behind the plane. If that test comes up negative change and fingers the pitot tube, we may need to modify the inlet or adjust its angle relative to the wing incidence. We’ll cross that bridge if we get there. For the time being it does work. Ultimately having a perfectly true ASI is not the most important. The primary reason for flying this machine is to know what the design is capable of, the limitations, and what we can fix next time. I think this prototype is not going to see tons and tons of hours before we ultimately retire it in favor of the next build. And so, having flown the prototype for the last year and learned many lessons, it’s time to start talking about the next version of LiteFighters.

Our engineers, Aaron, Paul and Shin, have been individually working on aspects of the design to find the critical items that need to be addressed for the Beta series. The focus is on reducing weight and drag, and adding just a pinch of stability, without changing what we know is a nice working setup. We do need to put the pencils down at some point, so it has been a hard process to just narrow things down to a finite list. To get there, we now have a punch list of key things that we will take care of before building any new LiteFighters.

Our biggest objective is to lose weight (target of 50lbs) from the airframe, while also adding retracts. Pretty self-explanatory there. Beyond that we have the following list of specific changes:

For the aft end:

Thin up empennage airfoils.

Move entire tail 3” up and 2” aft from FW datum.

Reduce elevator area by 10%

Allow vertical offset to combat P-factor.

Add electric trim to rudder.

Improve hinge design to use typical spherical bearings.

Cleaner mounting scheme between tail surfaces and frame.

Modify Horizontal/Elevator for easy trailering. (Currently too wide for doors)

All these changes are meant to improve performance but also happen to make the aircraft more accurate to the original Curtiss look. A typical sport plane of our size could reduce the tail volumes even further, but that quickly starts to hurt the fighter-like appearance. Future LiteFighters based on other warbirds will have subtly different solutions to their empennage, and we’ve decided to generally put a little more emphasis on looking correct where possible.

For the wings, we have a similar list:

2 additional degrees of dihedral.

1 degree less washout.

Shorten ailerons and move them outboard.

Blunter aileron LE. (Less Frise.)

Add 6” total to wingspan.

Shift wings fwd 2” towards datum.

Update wing joint and pin design for higher G-loading w/ quick remove wings.

Add wheel wells and other provisions for retractable gear.

Internally we have been cleaning up the structure to be easier to build, easier to work on, and address some issues that caused some serious weight gain in the prototype. This will contribute heavily to the Hawk’s diet plan.

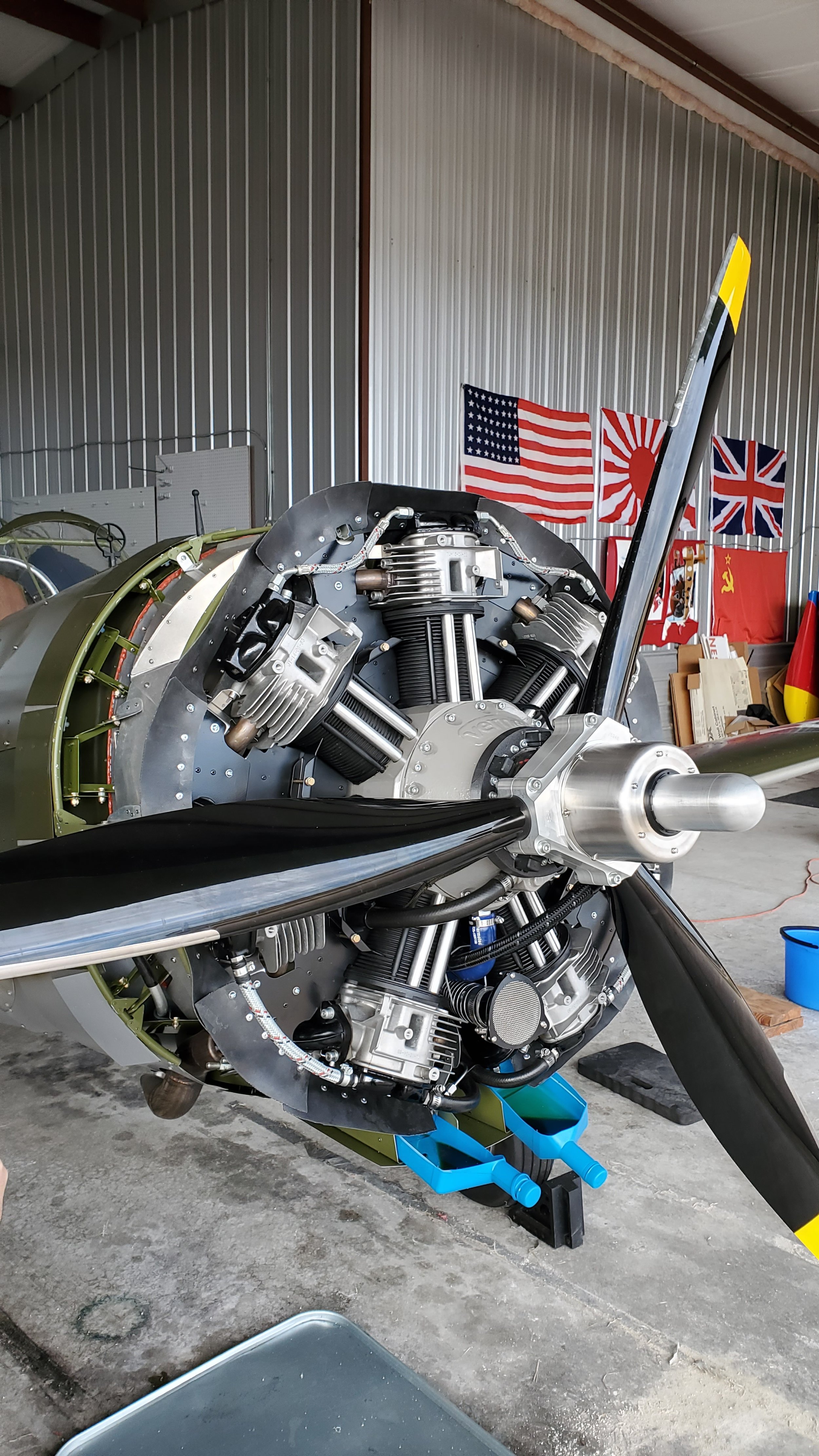

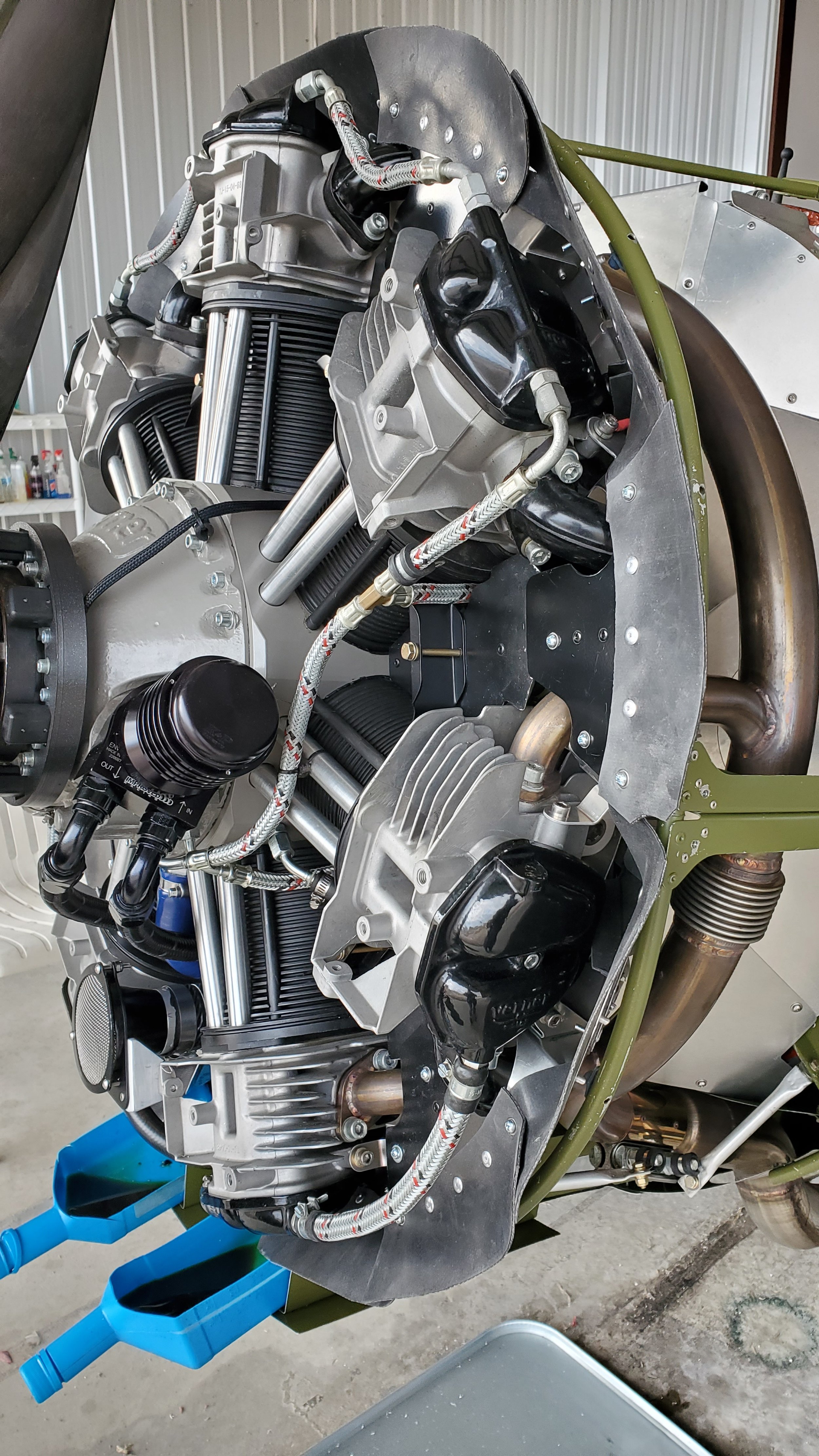

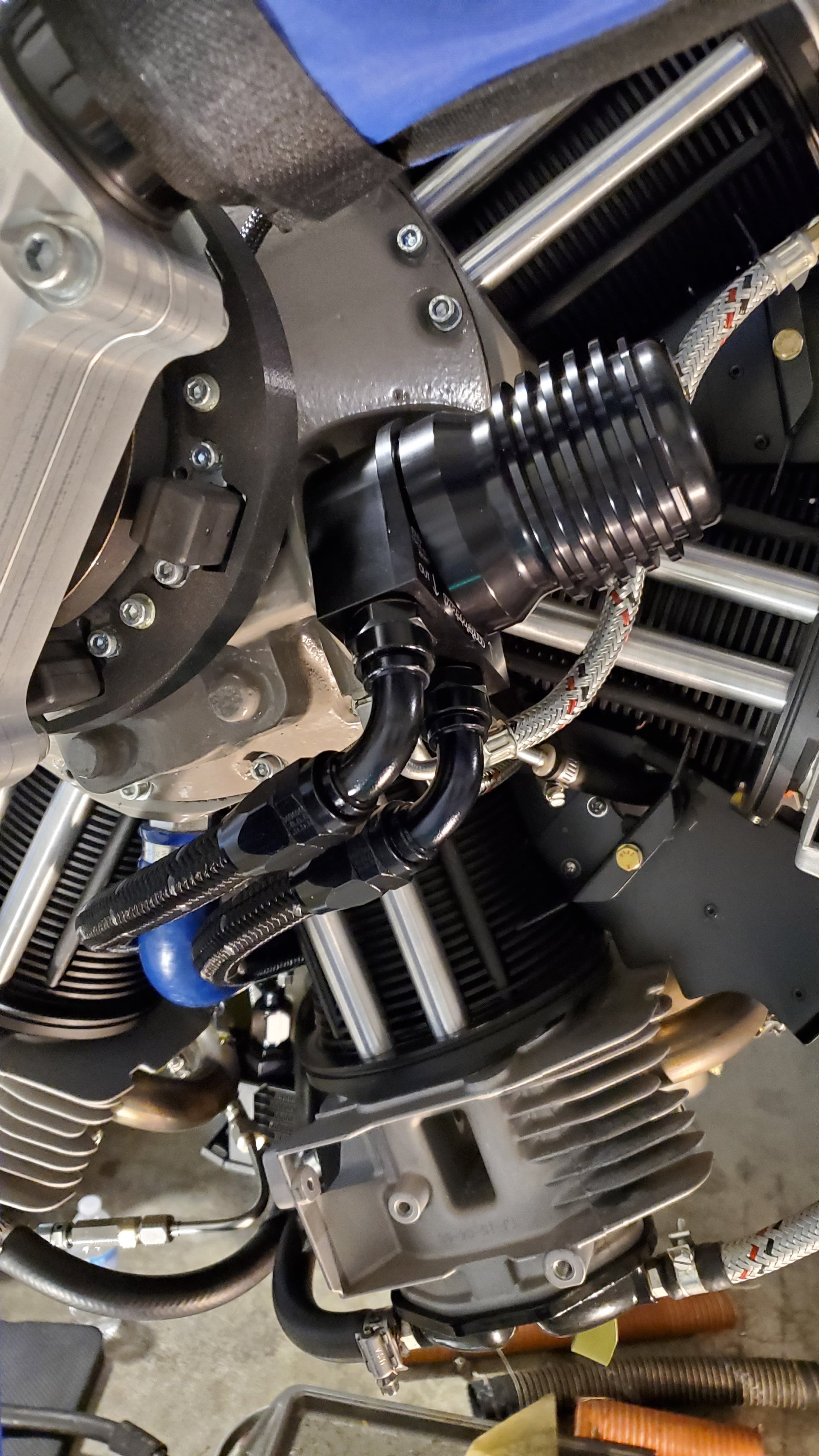

As far as powerplants go, one reason for moving the wing forward is the concession that we will be looking at balancing a heftier range of motors. The original design spec called for engines in the 80-140hp range. As the design sits today, I don’t see anyone getting it done with less than 100hp. Our 124hp from the Verner 7U is getting it done, but it isn’t blowing anyone away, so I wouldn’t recommend any less than 120hp even for those who just want an LSA per the current regulations. The P-36 prototype with fixed gear makes a solid LSA! But not everyone wants an LSA.

Many customers are interested in using the biggest engine we can handle. After looking back at our scaled drawings, and our engine cowl volumes, and the adjustments we propose, the good news is that we should be able to handle engines up to around 200hp and 300lbs in the LiteFighters. The bad news is that there aren’t many aero engines that are both 200hp and 300lbs and fit the cowling to choose from. But there are real options in the 120-175 range from Aeromomentum, Rotax, Verner, Viking, UL Power, and others, that could fit the bill. These engines, and the key adjustments to the airframe, look like they can get the higher-end performance where I want it to be: 145+ mph cruise, 175+ mph max, and still maintain the very gentle and low speed stall.

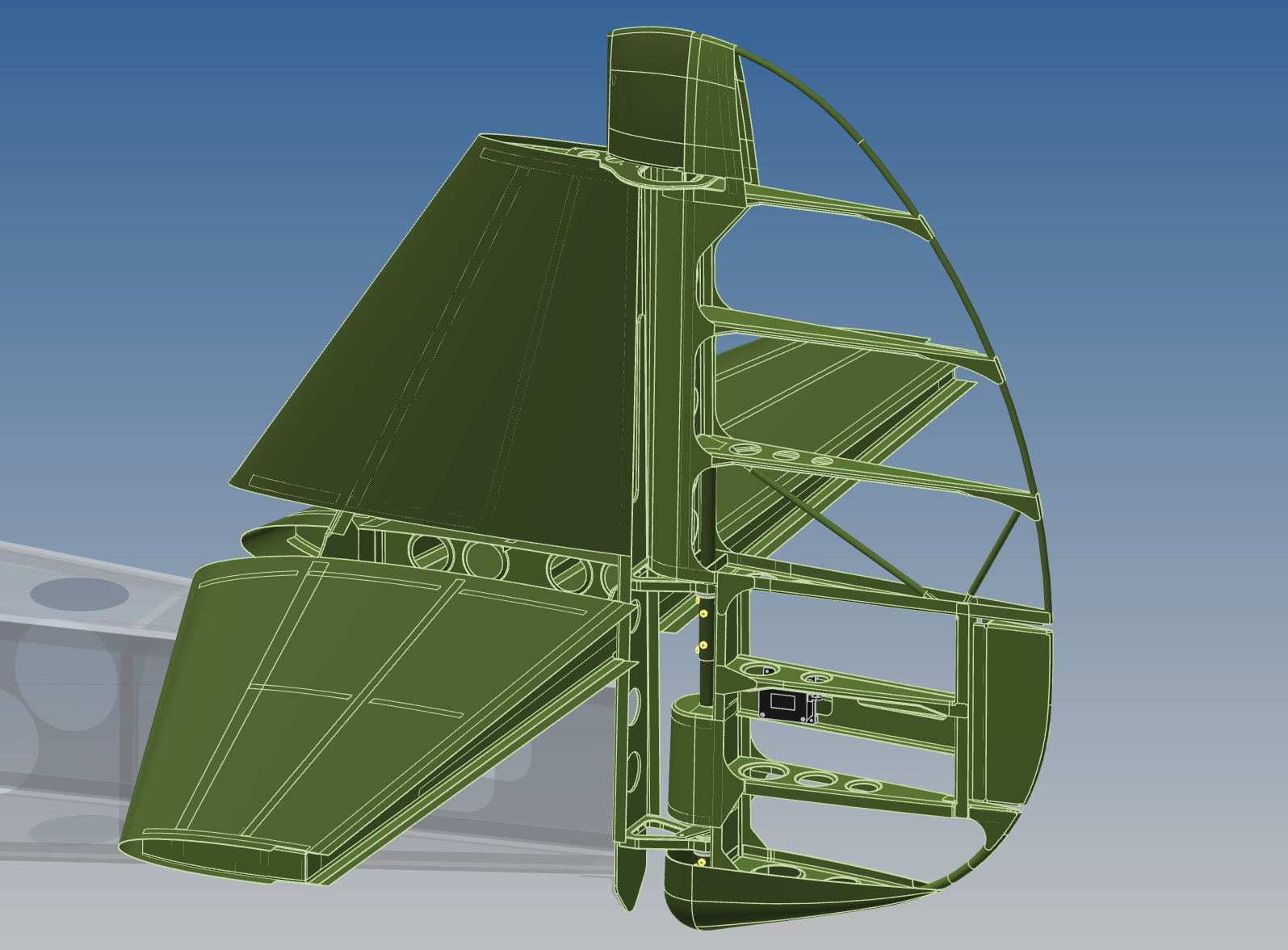

Scott has been working on the 3D CAD modeling effort to address the above changes and get us closer to making parts. The changes in the aft end are the current focus as we plan to start our Beta builder program with an aft-end kit. I can say that the adjustments really help with the lines and feel a lot more authentic. The P-40 will blow you away! As he gets the models closer to a finished state, we’ll be sure to do a detailed update with views of the old and the new so you can appreciate what we’re talking about.

Another note, since we are making these adjustments, they need to be re-validated. We will be building a new test set of all the structures to check the patterns and fit, and then we’ll verify the load capacity before we commit to the Beta run of parts. Same will go for the updated internal frame. The good news is we’ve done all of these parts a few times by now, and they go quickly once the ‘kit’ is made.

In all we confirmed from the last year of flying and working on the P-36 that there was more to do than just package up what we built the first time and send those parts out the door. Its been needing a bit more refinement in some key areas. You know, we have many skills and in some ways it’s amazing we have been able to keep working on this for so long. But we also have had to learn a lot along the way, work to address issues on our end, and there is more to go. So I appreciate all those who have had patience and offered their encouragement and assistance along the way. Looking at the list of what’s left, we’re finally seeing the light at the end of the tunnel and have begun preparing to move to this new chapter for ScaleBirds. There is a lot to look forward to in 2024 and we have been putting together a roadmap for the new year.

So to close things out for this update and for the year, for those who are waiting for your own Hawk, Tomahawk or Kitty Hawk kits, thank you for following along with your encouragement and for your patience with our process. For those who have come to us over the years for Verner engines, with support questions, or have been waiting for parts and accessories, thanks for your continued support and patience; we hope to hear more of your radial projects rumbling through the skies in 2024.