Made It to AirVenture 2023

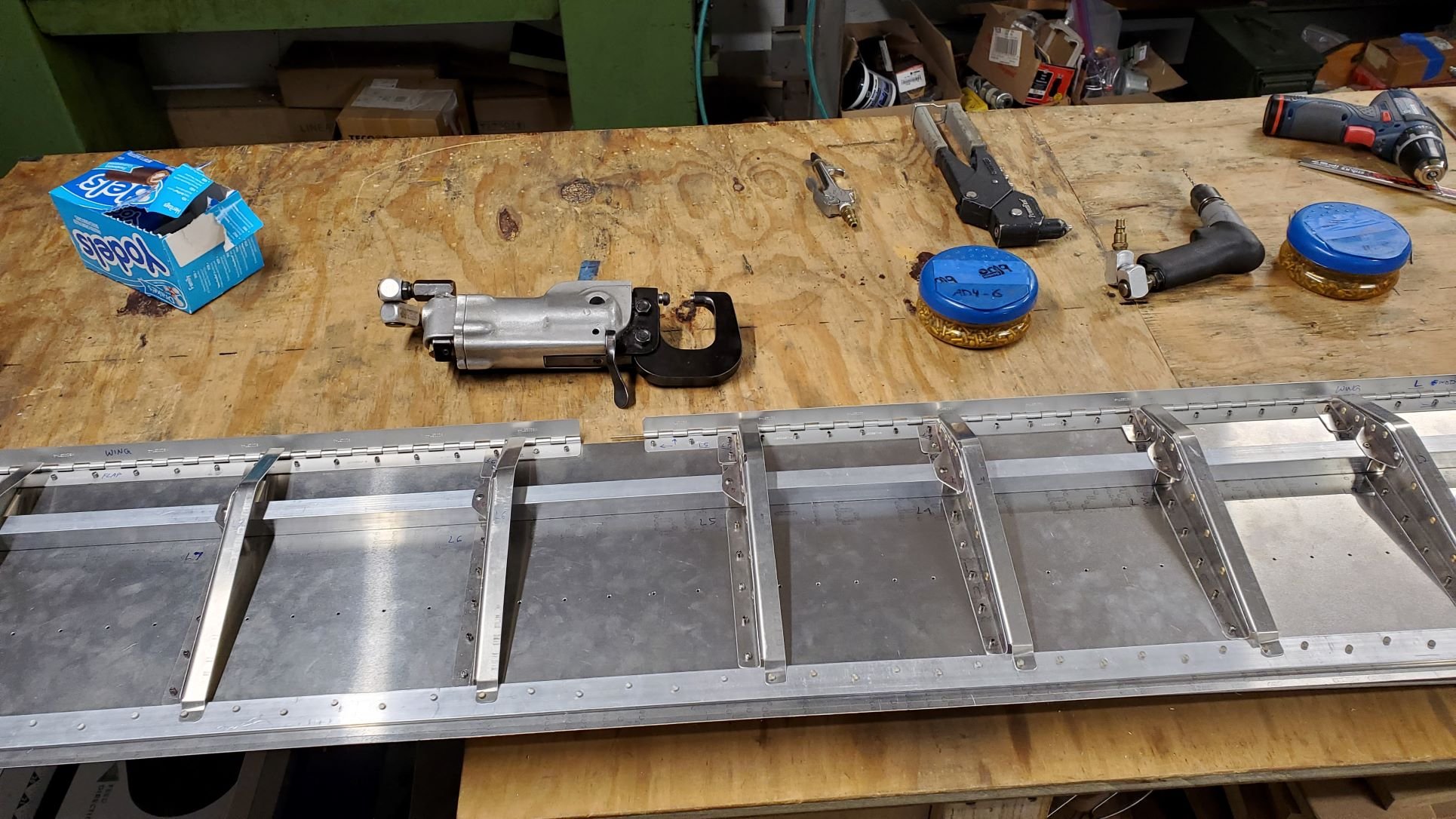

Hey guys. We made it to Oshkosh by Saturday evening at 7pm. Karen, Scott, Jennifer and myself left on Friday morning about 11 am pulling the trailer with the P-36 in it. Spent the night in the Cleveland OH area. There were some heavy but brief showers in NY state, then mainly clear till we got to the Wisconsin border. We stopped at the Russell Military Museum at Exit 1. We have been seeing the place for years but we never have the time to stop-in. This year, we are about a day earlier than usual and decided we needed time out of the truck and walking around. What a cool place! Lots of Armor, trucks and aircraft. Cool stuff too. Spent about an hour (not long enough) and then left as a storm was approaching right as they closed-up at 5pm. Rolled up to Milwaukie and hit some heavy rain. Then it cleared and we had a good ride up to Fond Du Loc and into Oshkosh at 7. We had enough time to figure out where our booth was and drop the trailer there, then got out right before another storm hit Oshkosh. Had a hotel lined-up in Appleton, WI Saturday night. Sunday we had a good breakfast at the Machine Shed restaurant, then rolled down to the show and our booth. We pulled the plane out of the trailer and attached the wings and tail. Then we buttoned up the fairings and installed the flaps and wing gap strips. We were mostly done by 11:30am but then had a bunch of people stop by the booth, so it took the rest of the afternoon to finish up. We met some people that have been following us and it was good to put faces to the names. Met Chris, the curator for the Connecticut Air and Space Museum. Sorry, really bad with last names. Chris is the guy who discussed with us about painting the plane to resemble Lt. Gordon Sterling’s Pearl Harbor aircraft. It is an honor for us to share his memory and story of bravery. Its a stunning paint job too! Many compliments today. Well done team!

Monday morning we start the show. That is when we put up our flags and posters, set out the signage and all while answering questions. Its a fun time till it gets hot in the afternoon. We do have an awning on the trailer to shade our table. That helps a lot!

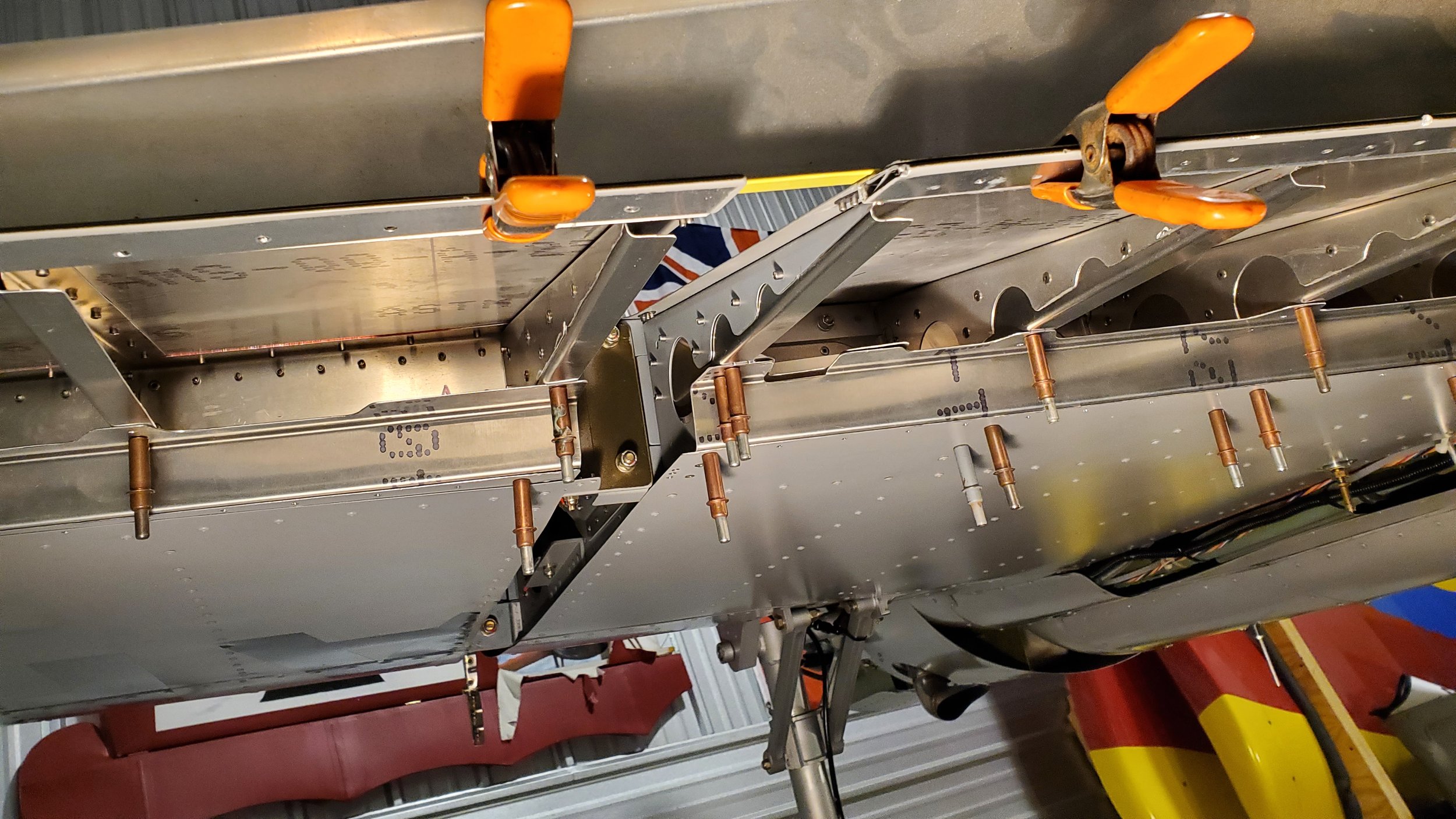

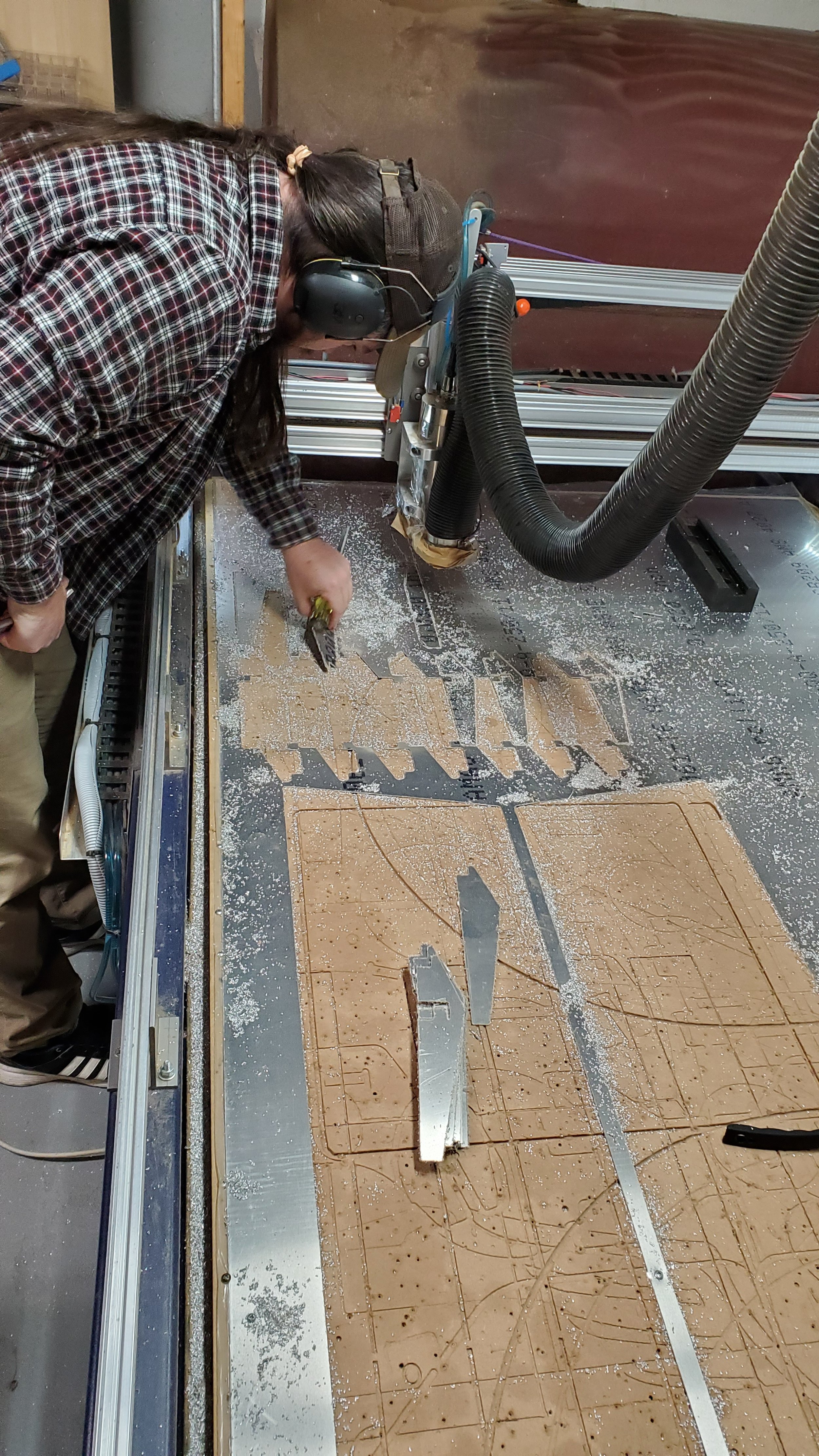

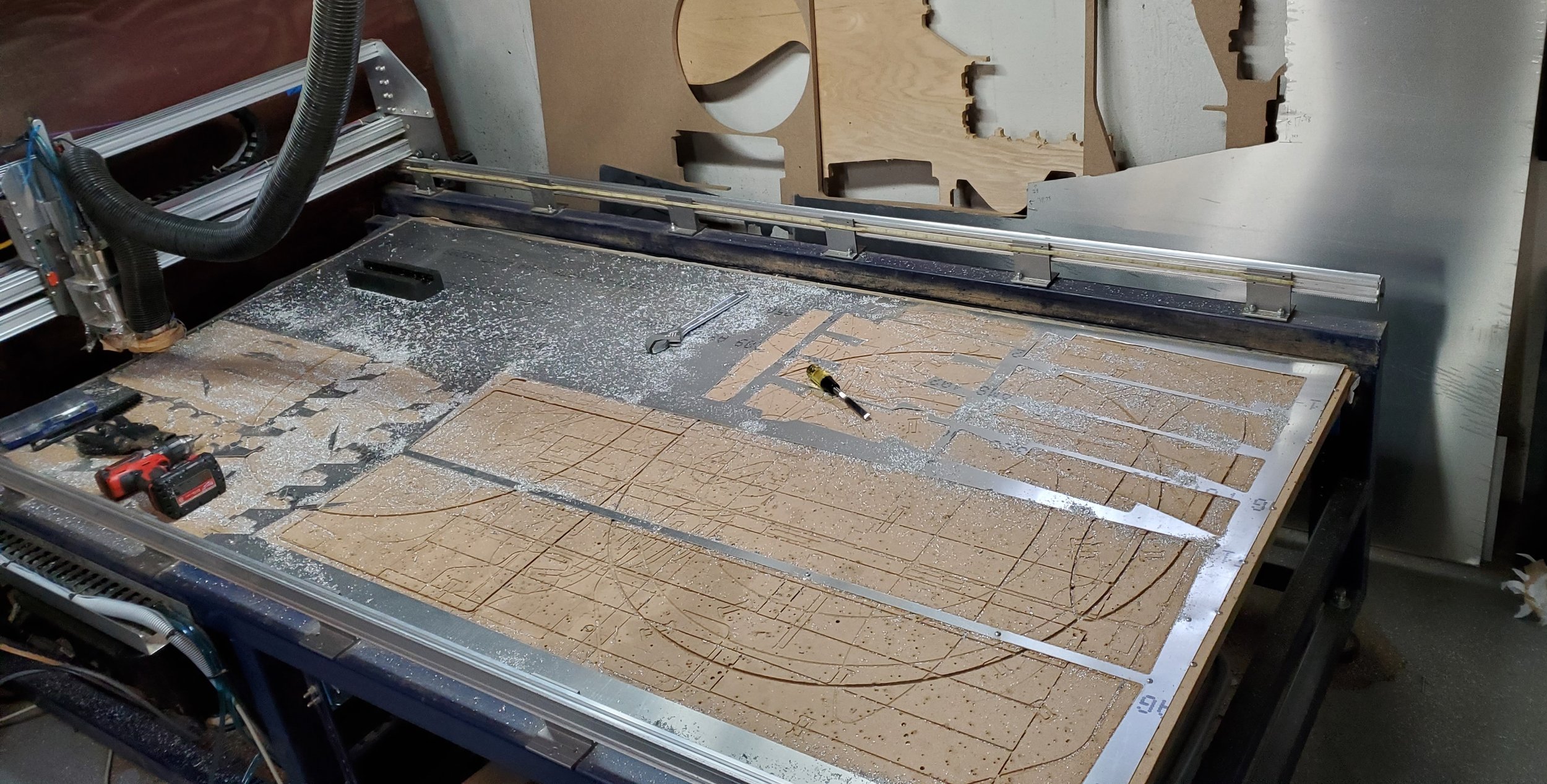

We watched many aircraft arriving and I love to see the Warbird arrivals. The F-16 was ripping up the joint! Right now its Sunday night. Scott is up editing our brochure to show the latest structure with flaps.

Hope to see some of you guys there! Will try to get some images and video to post. More later!