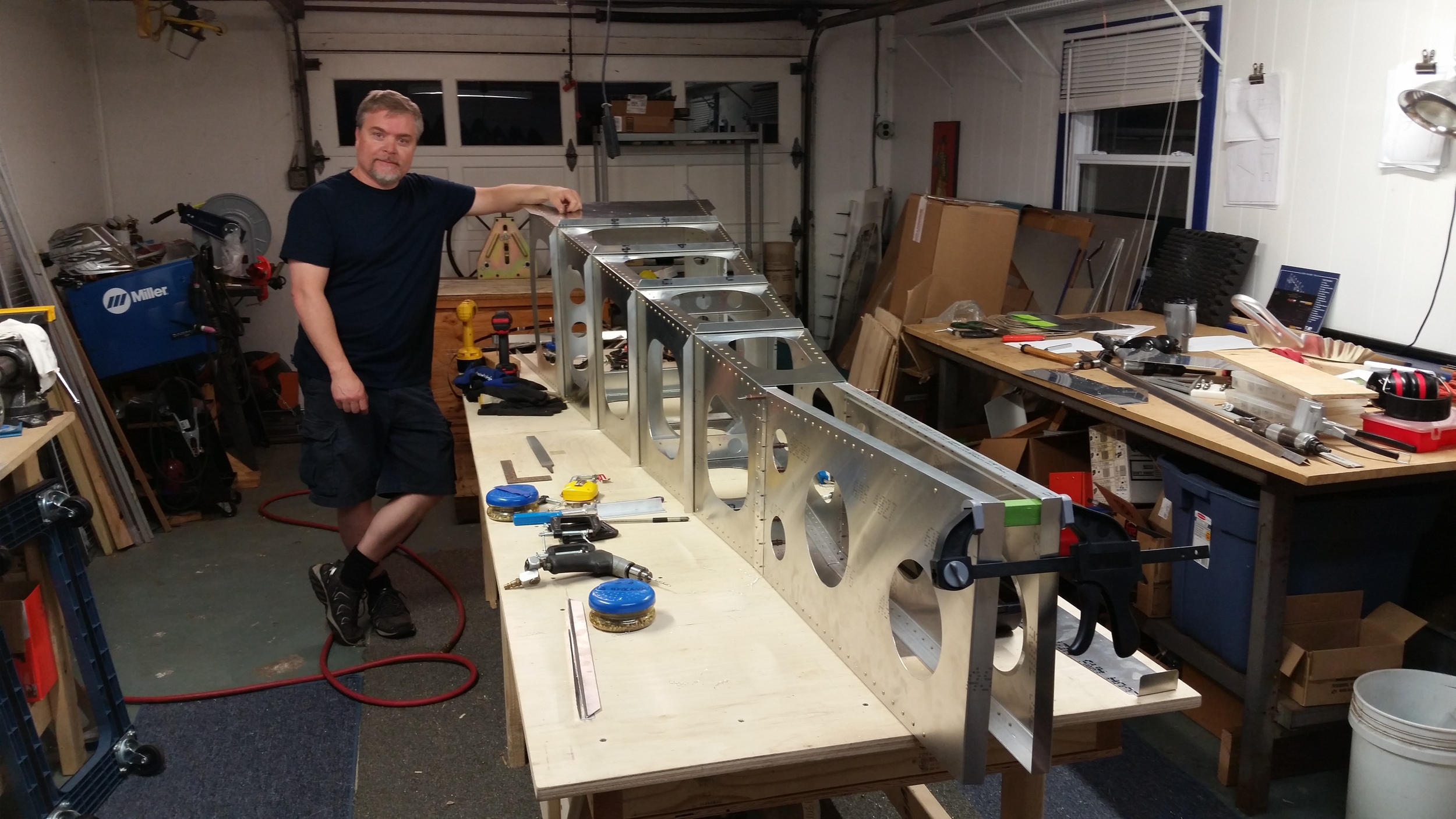

Been Workin

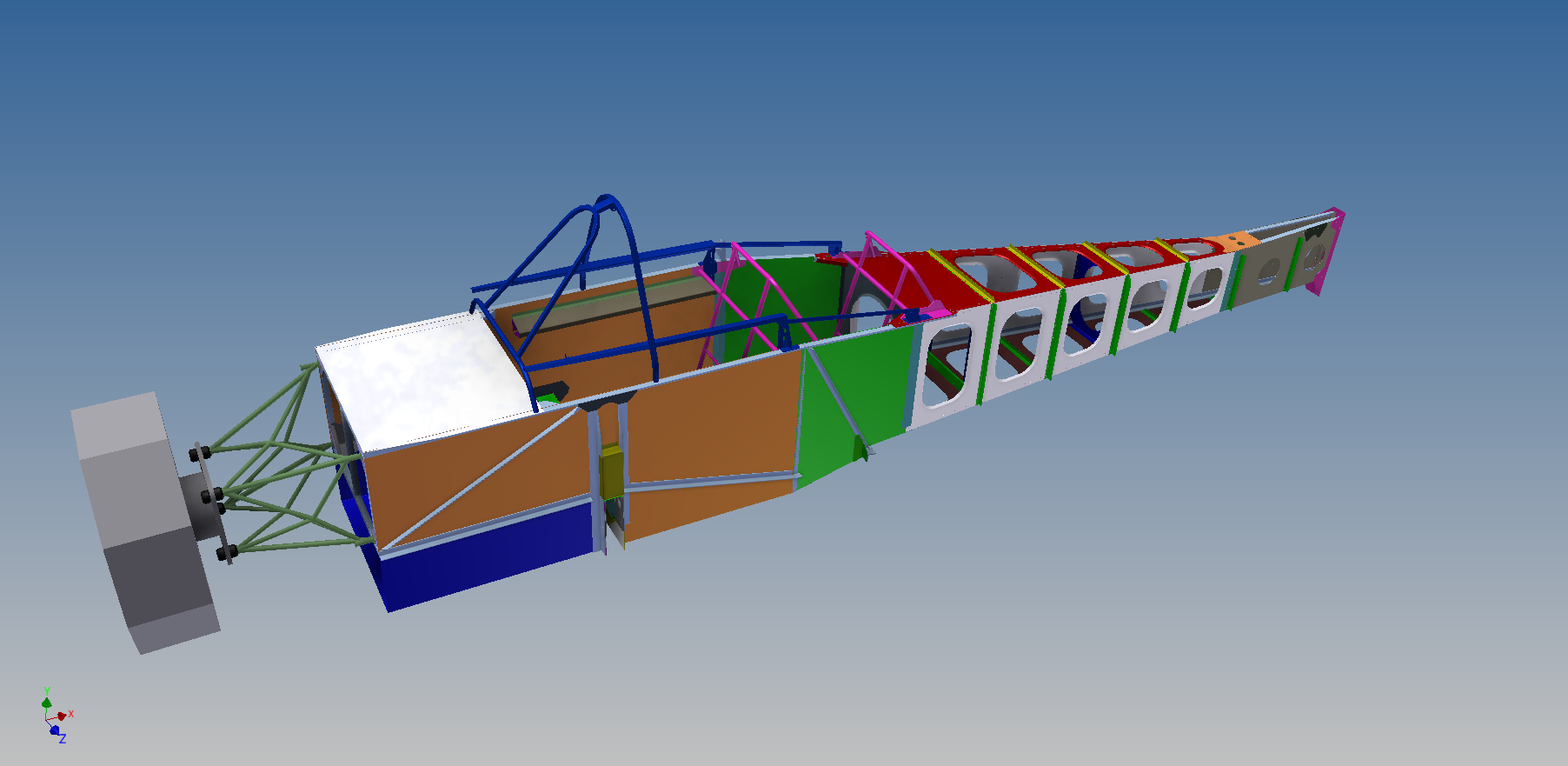

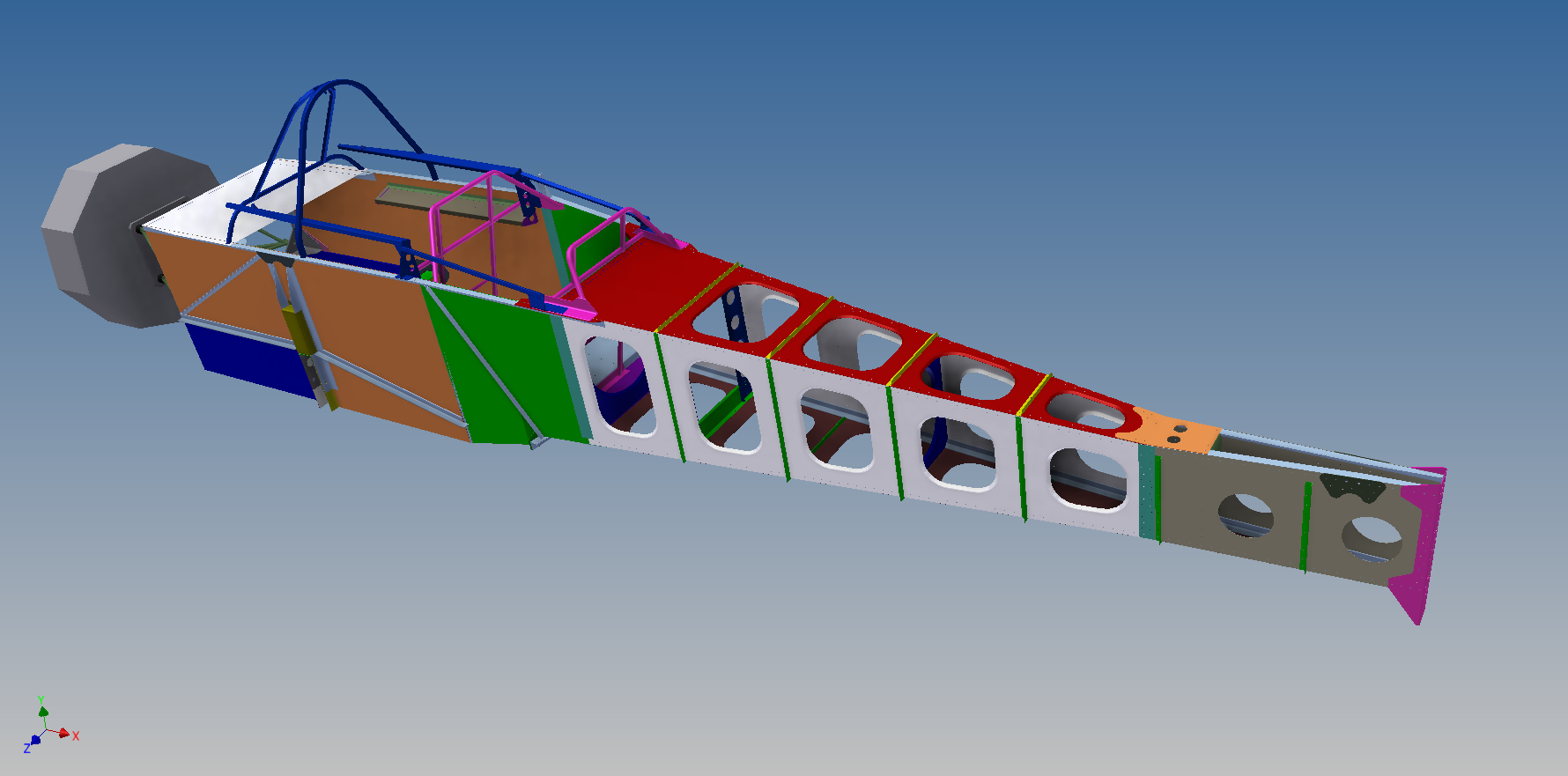

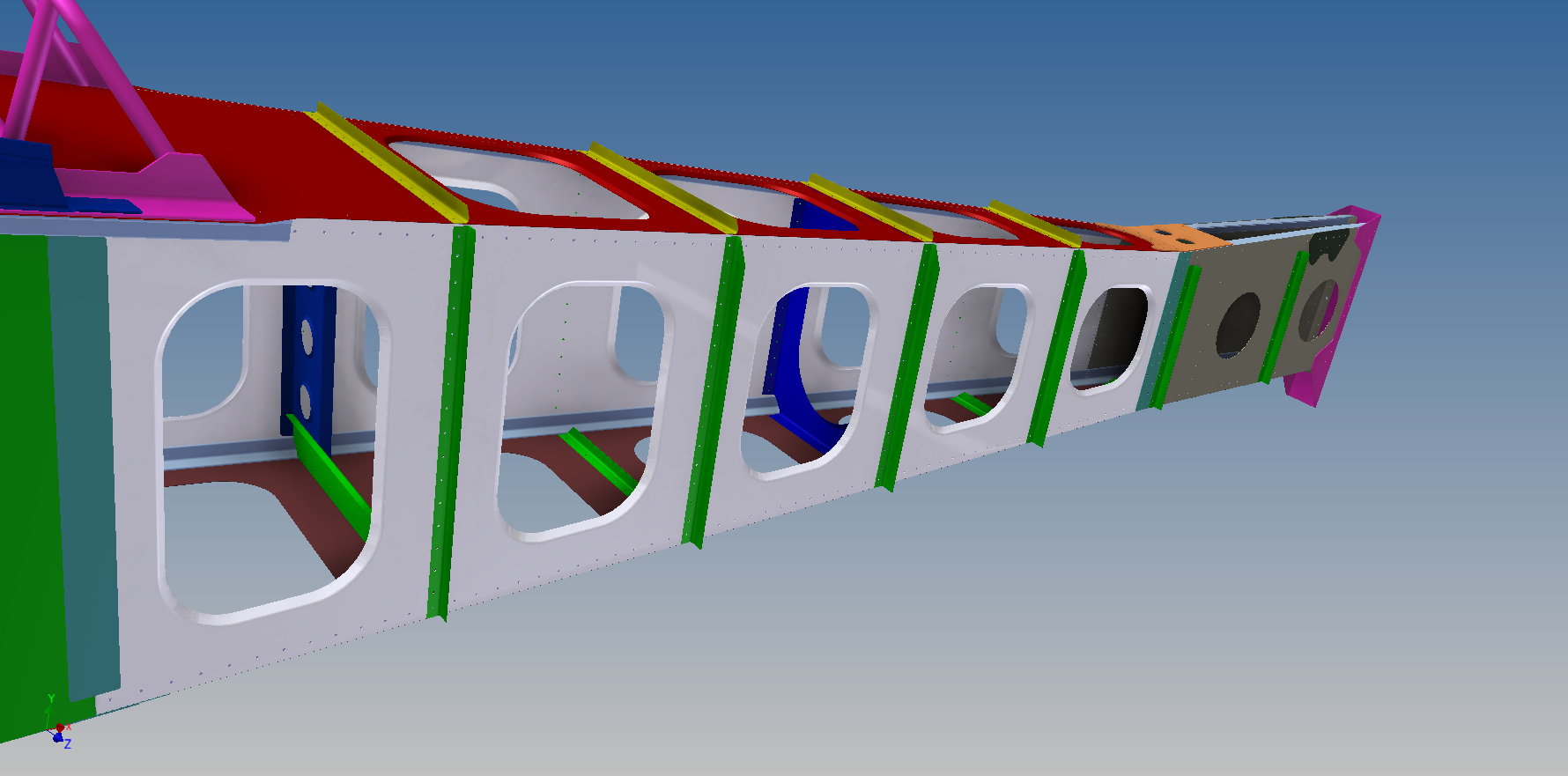

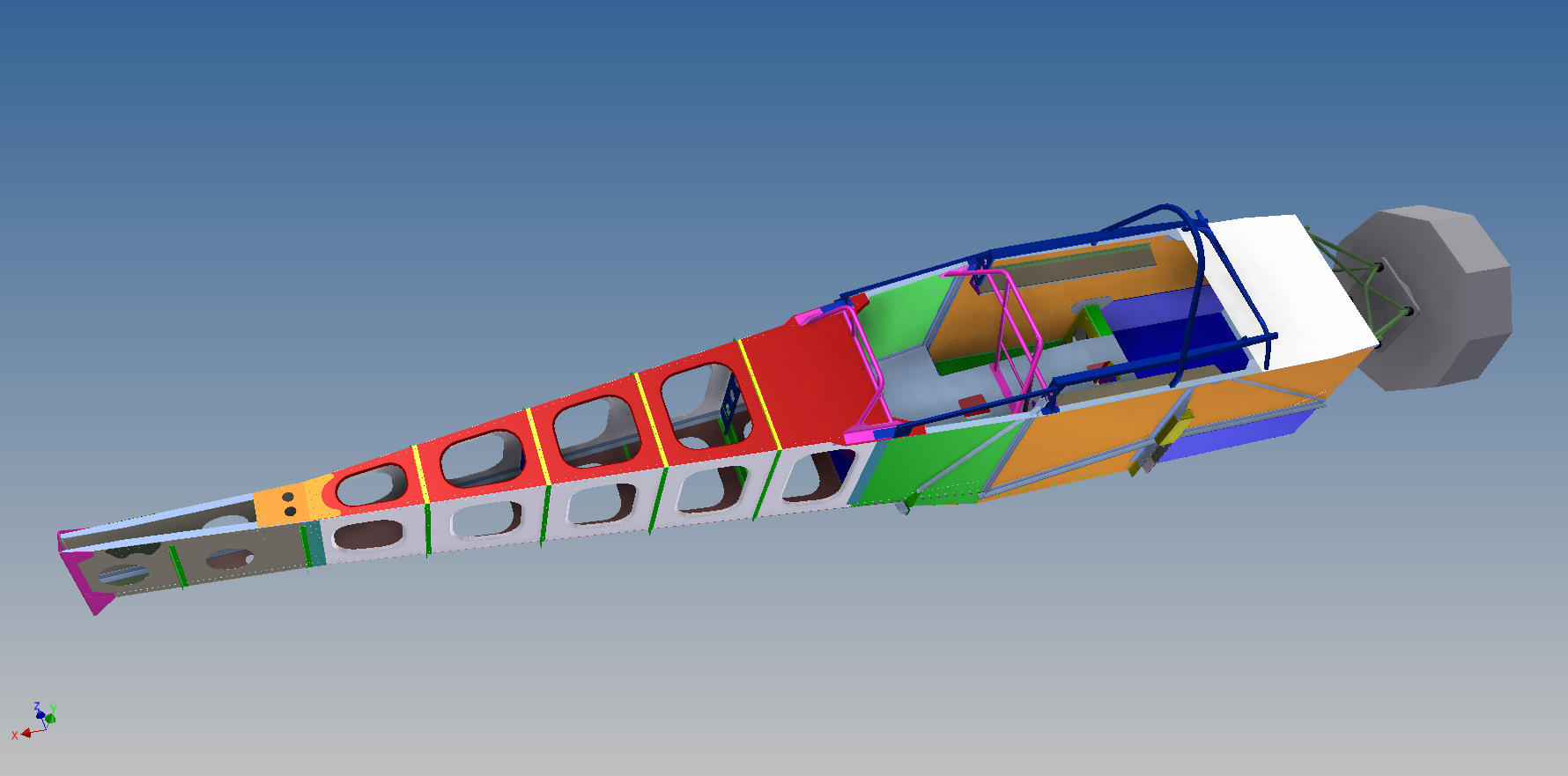

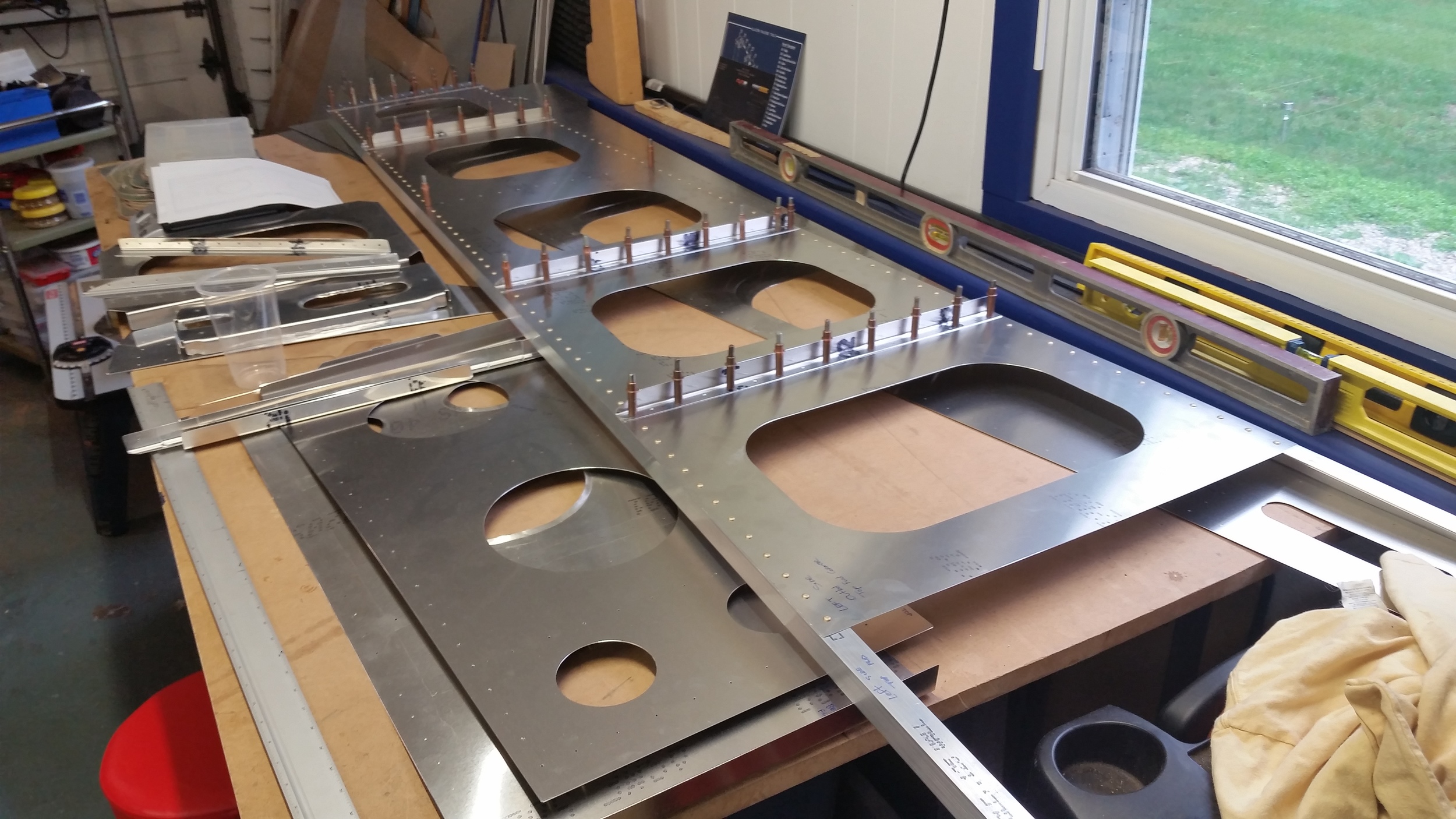

We finished the testing in August and you may start to wonder – what the hell were we doing since then??? It’s the end of January 2016 now. So sorry to have been absent, but we've been working hard! We have been back to the lab again, doing a lot of detail designing and modeling. We’ve taken the lessons from the load testing and empennage builds, and been busy incorporating them and fleshing-out the design of the whole machine. Lots of small changes, and a few big ones! Our whole design team went on a field trip to Titan Aircraft in Ohio in September. John Williams spent over four hours of his weekend with us talking shop, showing us his whole operation and how they make every part. John was very encouraging and interested in the Hellcat. He is a real presence in the replica fighter world today as you all might well know, and we learned a lot from him. A primary reason to for the visit is that after some looking at it, we intend to leverage the landing gear components from the Titan 51 as a base for our own gear. The landing gear of the Hellcat impact the layout of the center section in a big way, and without a solid design for them we can’t proceed with the rest of the wing.

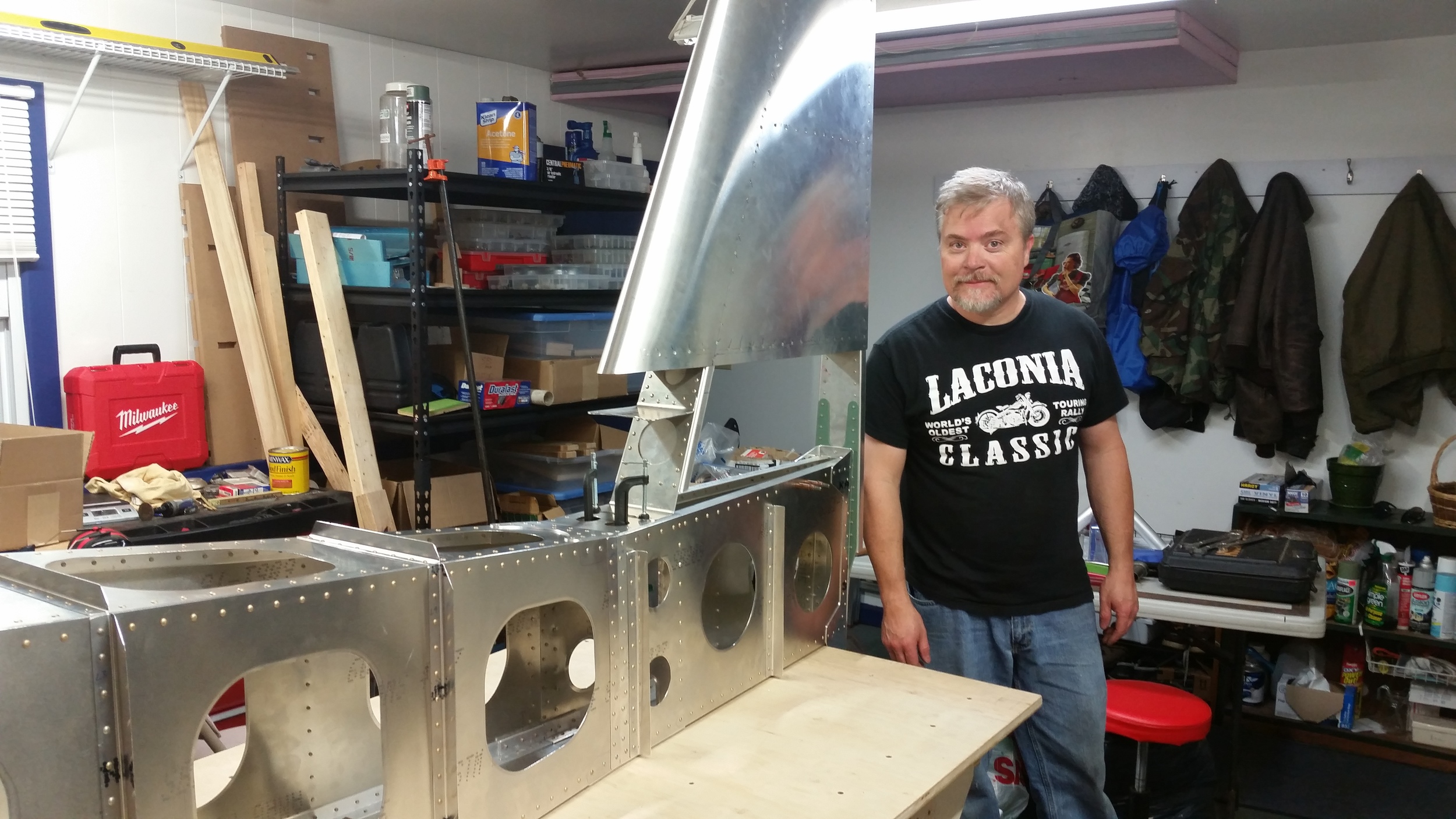

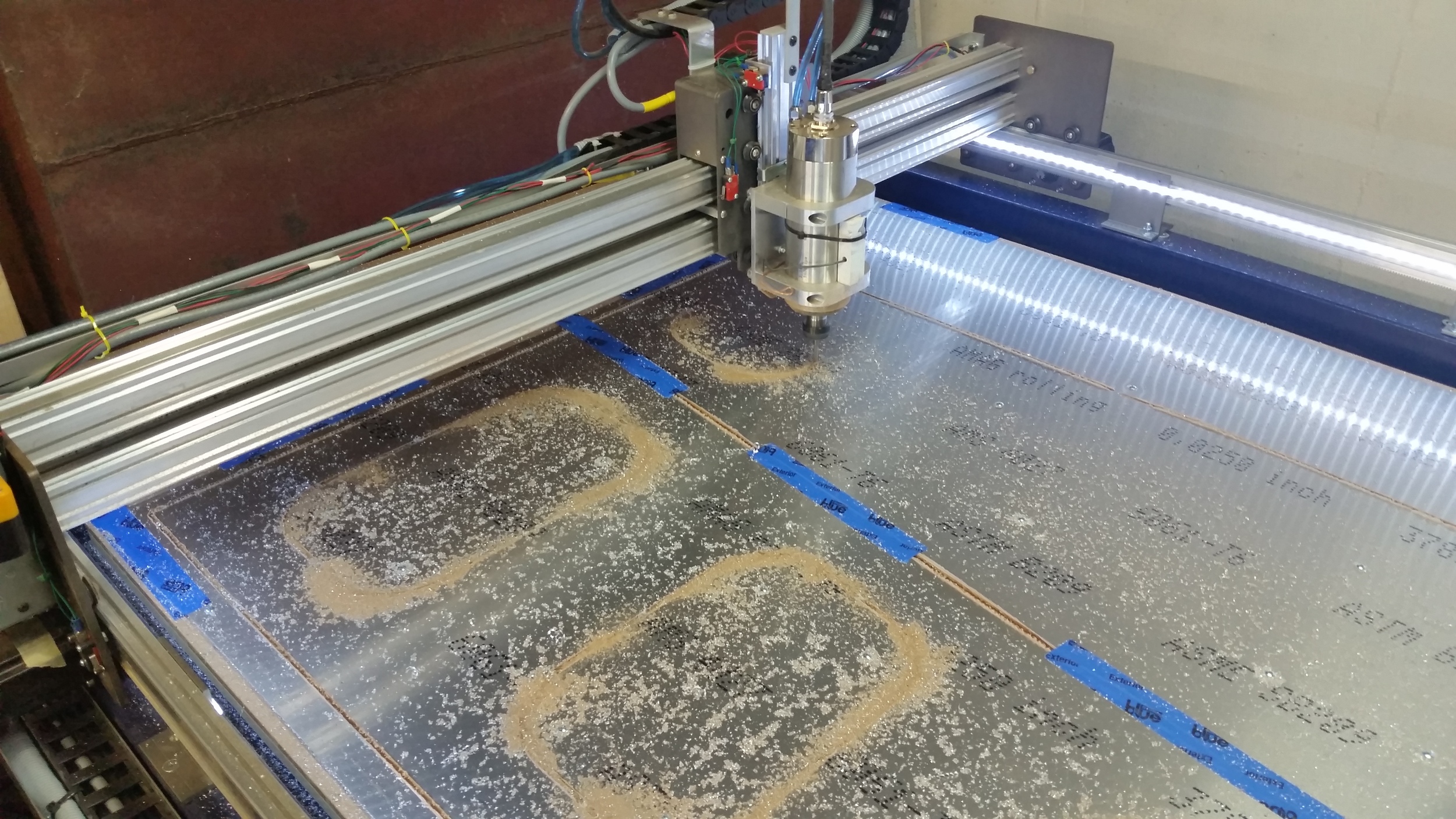

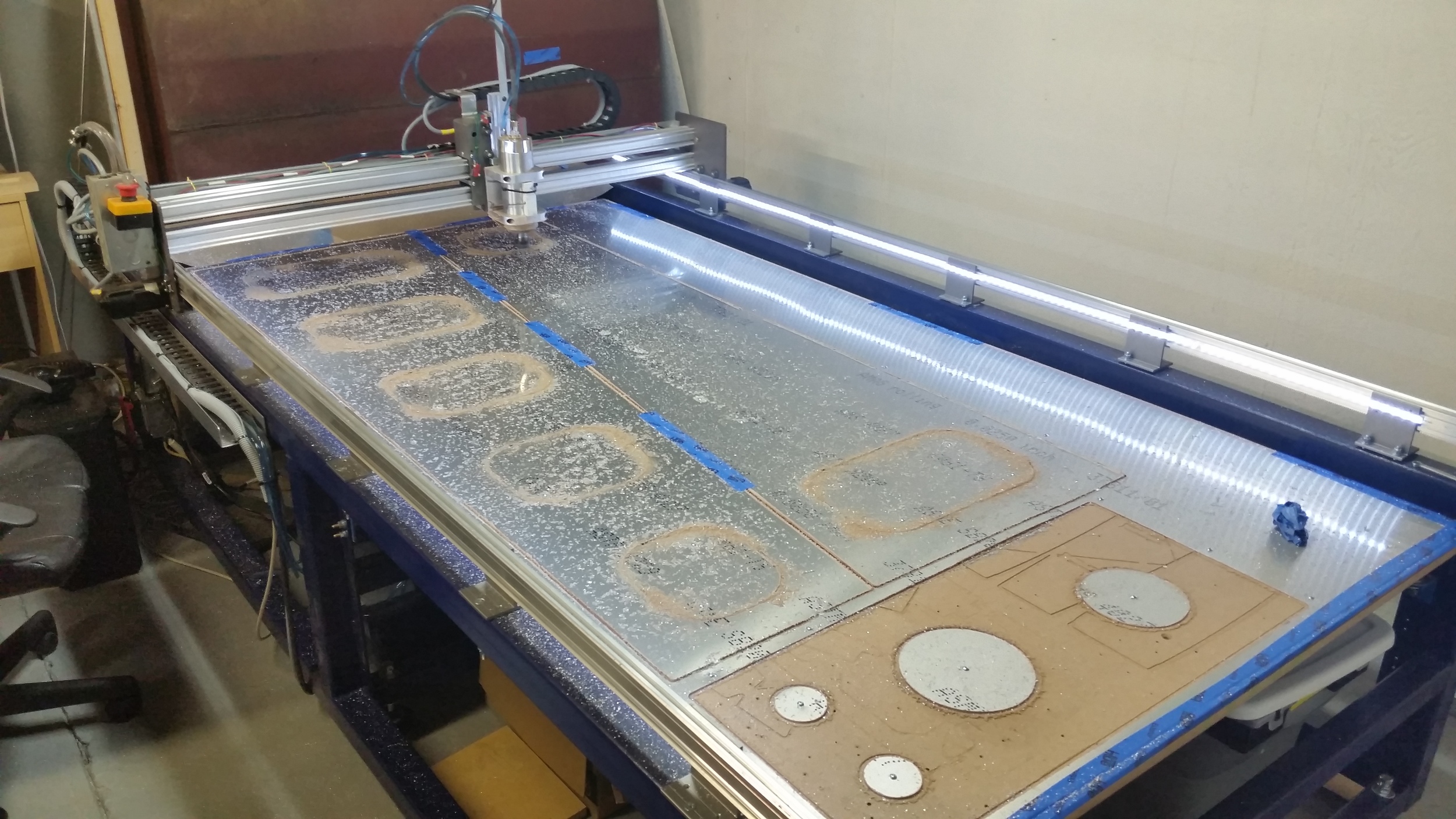

We did get another distraction this fall in the form of more equipment. My son Scott decided to buy a small vertical mill and convert it to CNC. This “two week project” turned into 6 weeks or more of tinkering and fabricating. Usually projects just do that. This mill is no Haas or even Bridgeport, but what we need is the ability to machine small, complex parts without blowing the budget. In fact it’s quite a nifty little unit called a Precision Matthews PM-25MV, sold by Quality Machine Tool and Scott purchased a separate CNC conversion kit from a guy going by ArizonaVideo99. It was a quality kit but more DIY than I was expecting thanks to the tolerances on import equipment. Scott decided after getting the thing working and crashing more than once, to go ahead and wire-up good proximity sensors. After two rebuilds it’s almost done now – just one or two cables to go. Then we need to spend time getting used to what it can do. But sorry to say, we didn't make more parts for the Hellcat, so we’re looking forward to get back to that this winter. Back to work!