Holiday Homebuilding

Hope all of you had a wonderful Thanksgiving and are preparing for a Merry Christmas and New Years.

I know it has been way too long since the last blog entry. So let me catch you up on where we are and what we have been doing.

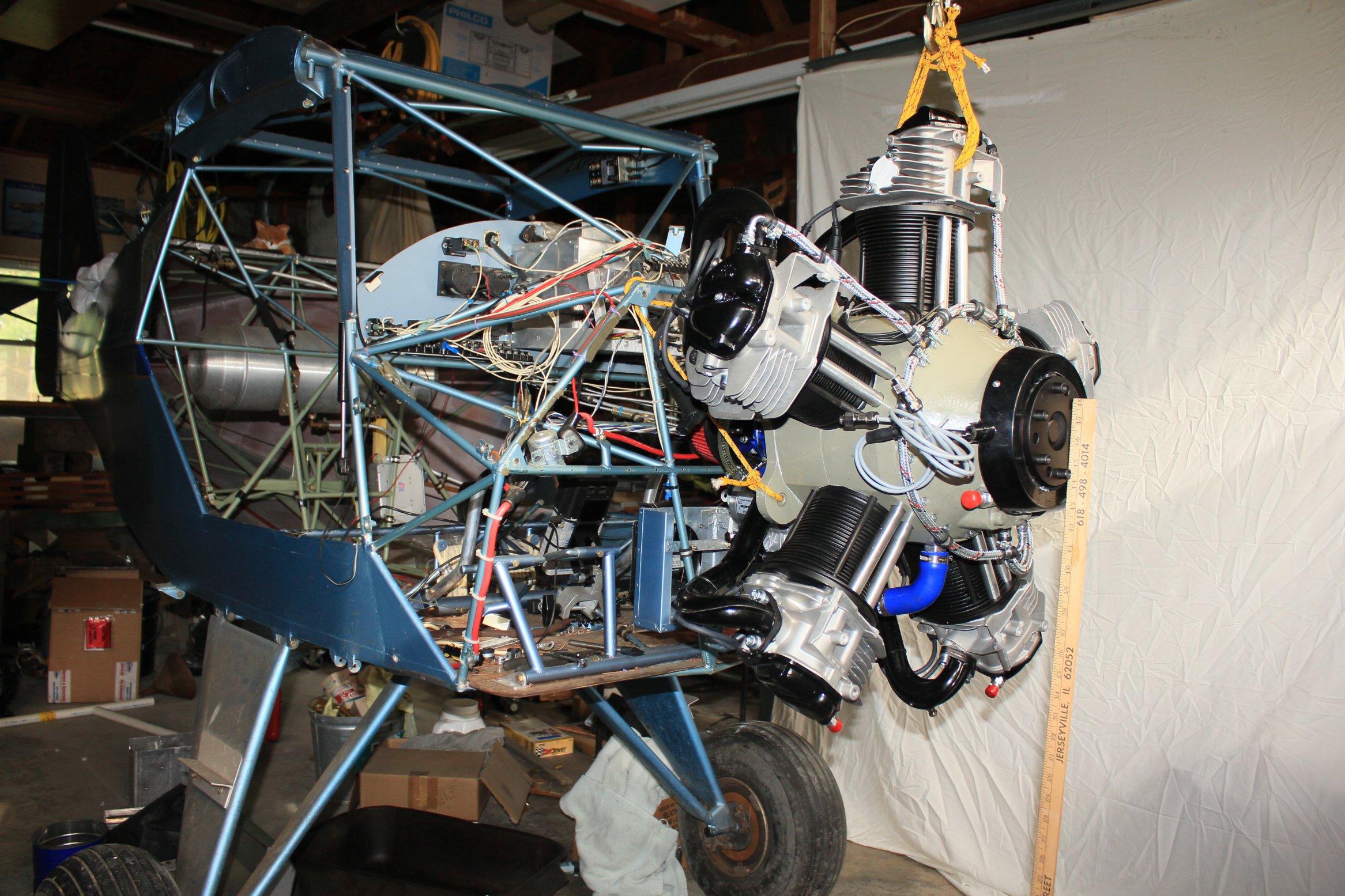

On the Verner engine side we have our first 9 cylinder coming soon, we expect it to ship shortly after New Years, and this engine is destined to be installed in a special airplane. It's a little early yet but I'm sure you'll hear of it soon. We're looking forward to seeing it at Sun N Fun 2018, which will be available for you to check out in person. We also recently sold a 5VW engine to a gentleman building a custom Ragwing Special which I think will make an awesome combination! My own Avenger is being flown when possible (though it seems every possible thing has been preventing me getting to the airport lately, all the while it gets colder.) Having finished the test regime I can say it is getting awesome fuel consumption – in part becuase I have to retard the throttle as soon as I get to altitude to keep from over-speeding the airframe. Right now I'm averaging about 3.4 gals per hour on the 83 hp 5 cylinder.

One of the lessons learned during the test phase was running into a stuck starter. The Verner being experimental and made using a many auto parts, it uses a common car starter. In my case, I went to go for a flight but I wasn't getting any action when turning over the engine. I've had batteries go dead which was my first notion; but after swapping batteries, and contactors, and checking my wires, we reduced it down to just the starter itself. So after pulling the starter to inspect it, we were able to simply tap it back into working again. Wish I had thought of that before pulling it. At any rate lesson learned with that, but also that if it happens again we'll need to look at a replacement part.

Counting the delay from that starter issue, I have now flown the plane enough hours that I've satisfied the steps to take it from its Phase 1 test period and back to Phase 2 operations. There's still things I'd like to change, (is a homebuilt ever perfect?) but for now I can say it's good to go.

On the fighter front we have permanently riveted on the fuselage top and side skins. This depended on many things being done in certain order but we finally worked through that maze. We had to finish the control stick assembly and elevator push tubes, rudder pedal installation needed to be completed, rudder cables were run and swaged, vertical needed to be fitted and bolted into place with the horizontal; tail wheel assembly had to be modified with the shock mounted farther aft to get a better angle to the ground so it would work properly. All of that work needed to be finished in order to get the rudder cables installed. We modified the purchased throttle quadrant to have a mounting plate that is easy to remove – a lesson learned from the Avenger engine installation work. Then we had to paint it to make it look right. The tail is now on – though it will need to be removed again for transport. We have been finishing details around the cockpit and canopy most recently: The side windows originally had a P-40E type of look and had to have some changes to match the P-36 Hawk look we are after, which is a longer, more pointed window shape. The mods required me to drill and cut into already finished skins and splice in some new panels. I almost cried to cut into a finished shape, but actually it came out great. So no spilt milk after-all.

So as of right now, we are forming the canopy and windscreen. We bought two quartz space heaters that we disassembled to make a very basic thermoforming heat box, which just barely does the trick for heating the plastic we need. It's not pretty or particularly good in any sense, but it only has to work a few times. The plastic sheets were heated then drape-formed over templates we made from wood and .032 5052 aluminum sheet, one for the windscreen and one for the canopy as they had slightly different overall shapes. The windscreen came out great, the canopy started to warp in spots from cooling but I think it will come out OK. If not I can make another! The windscreen was trimmed and fitted, and I'm in the middle of installing that permanently now.

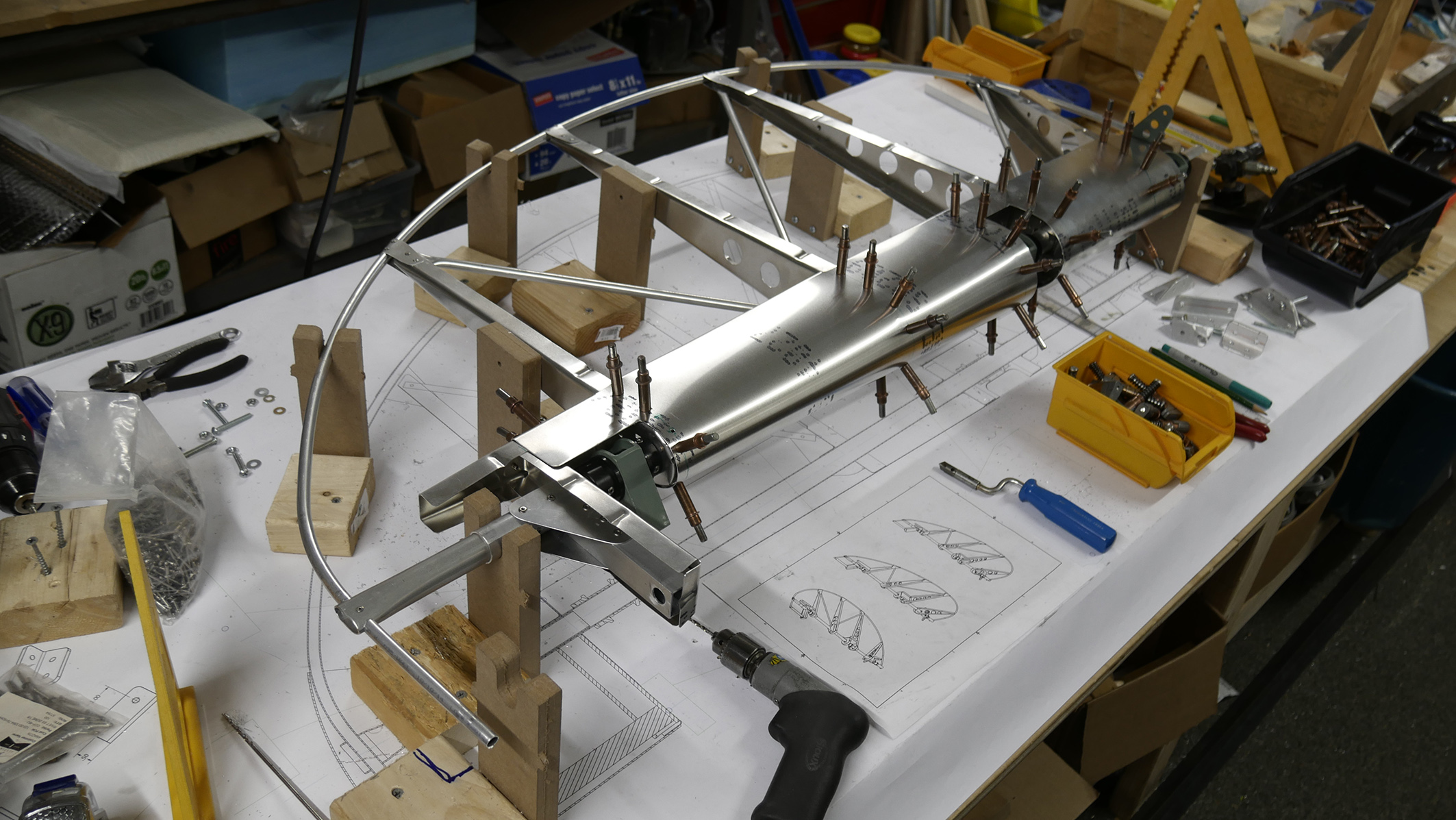

The other project that Scott is working on is cutting out parts for the elevators. He spent last month modeling those, and so far it looks quite good. The rudder taught us some lessons and so improvements have been made. The aluminum has all been cut on the CNC but it has to be sanded, deburred, and cleaned up before forming. The forming blocks and the full-scale template have to be made but those things go quick. There are also some steel pieces that have to be made up, but overall we're pretty close. It seems that making the raw parts is about half the battle with these things.

The latest CAD work involves the center section of the wing and the retractable gear mechanism. We've decided for sure to add retracts to the design as everyone says it really needs it and we can't really disagree. So we have been working on making that a complete design so the center section can go forward. The rotating gear leg to bring the wheel flush with the wing is an interesting challenge but we think we can make it work.

We are pushing this to get the elevators after Christmas and then work on the wings and landing gear through the rest of the winter.

As we prepare here for Christmas and New Years we hope you all are able to enjoy the holiday season, Happy New Year!