Some Progress!

Hey everyone. Sorry its been a long time since I did a blog entry. Been very busy with design, engineering and engine sales work. Also, with the winter weather getting closer and closer - its here now, I had to do some scraping and painting on the house and some chores that I was putting off. Did I mention raking leaves? Aargh!

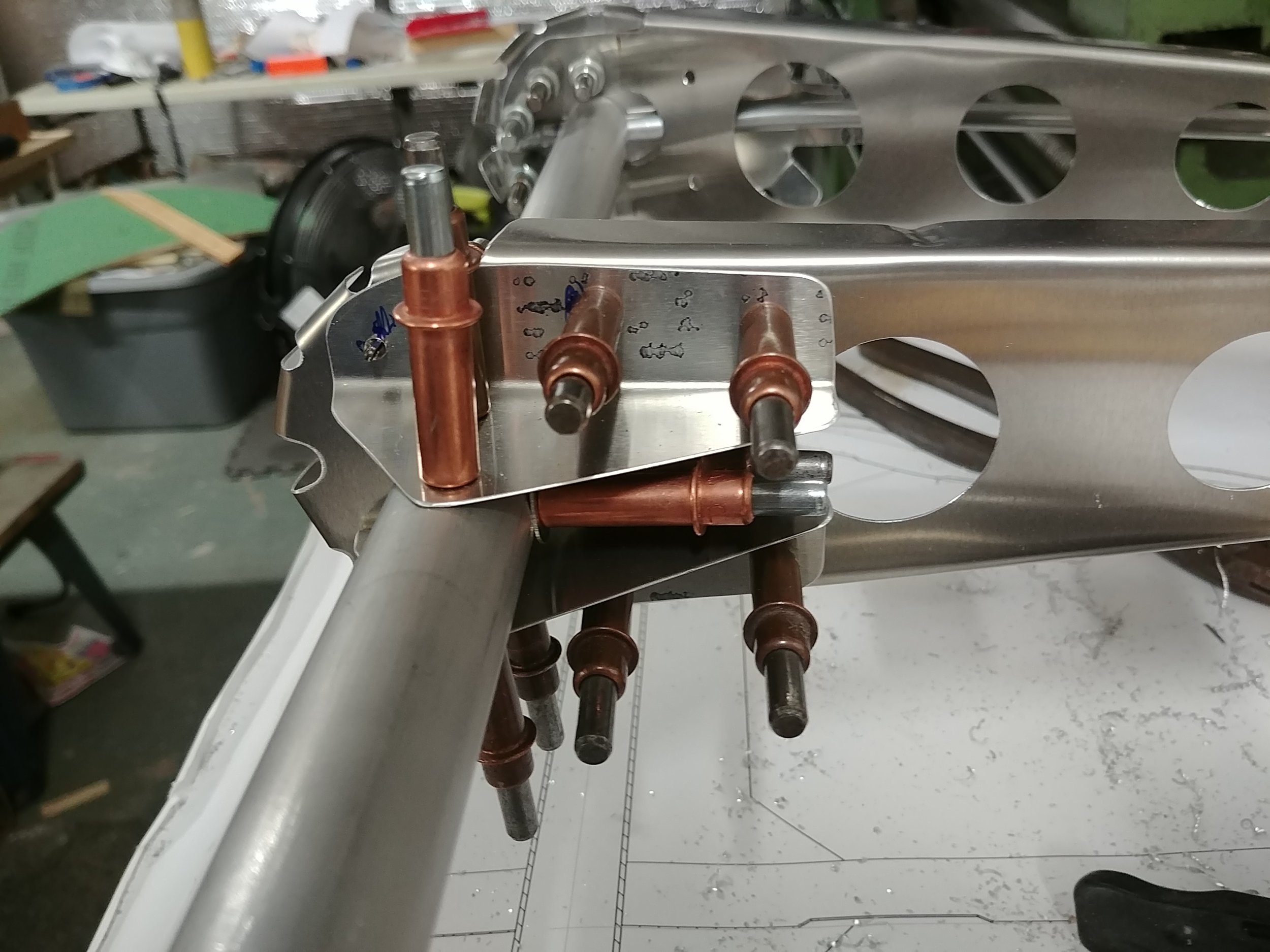

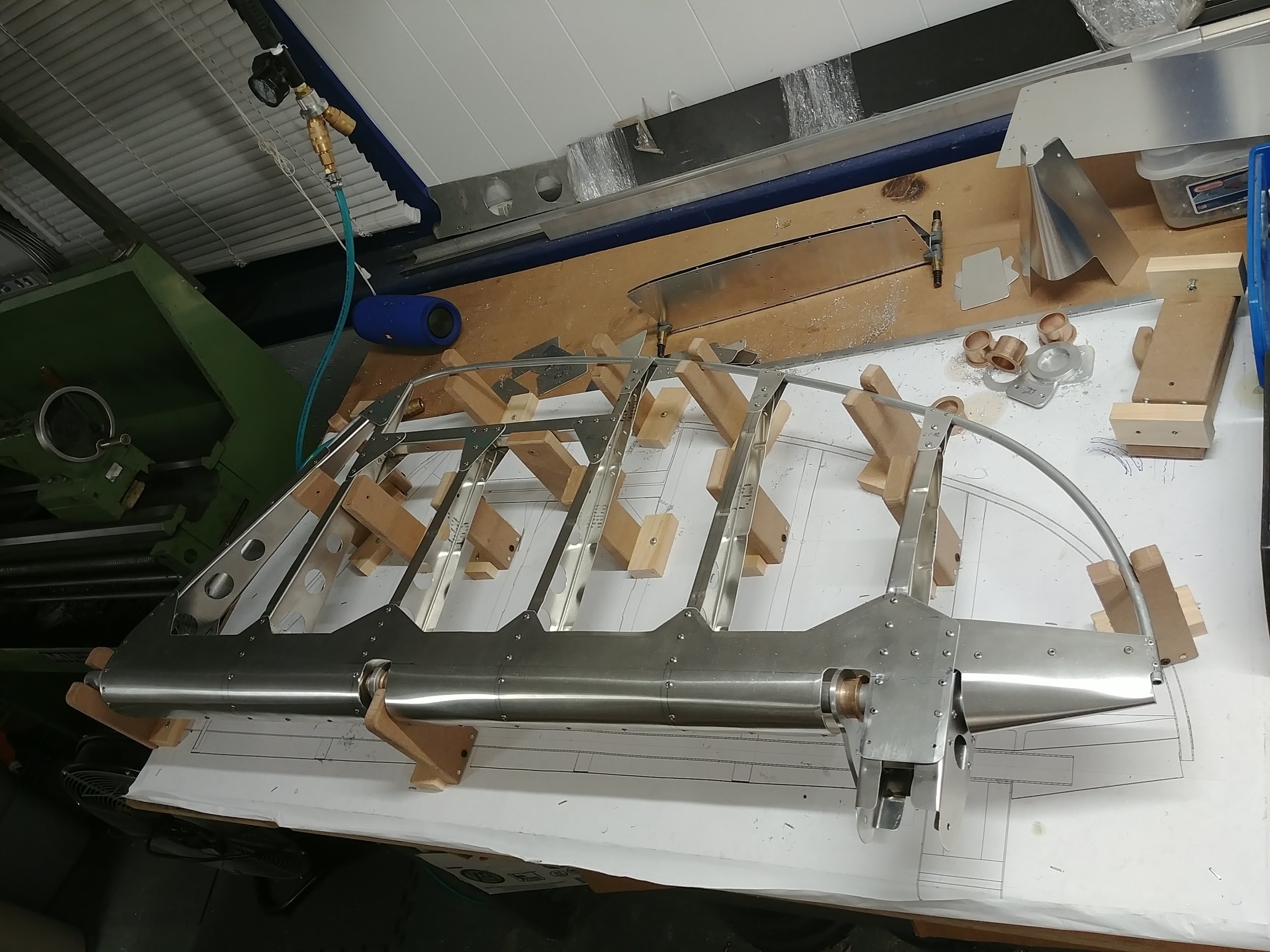

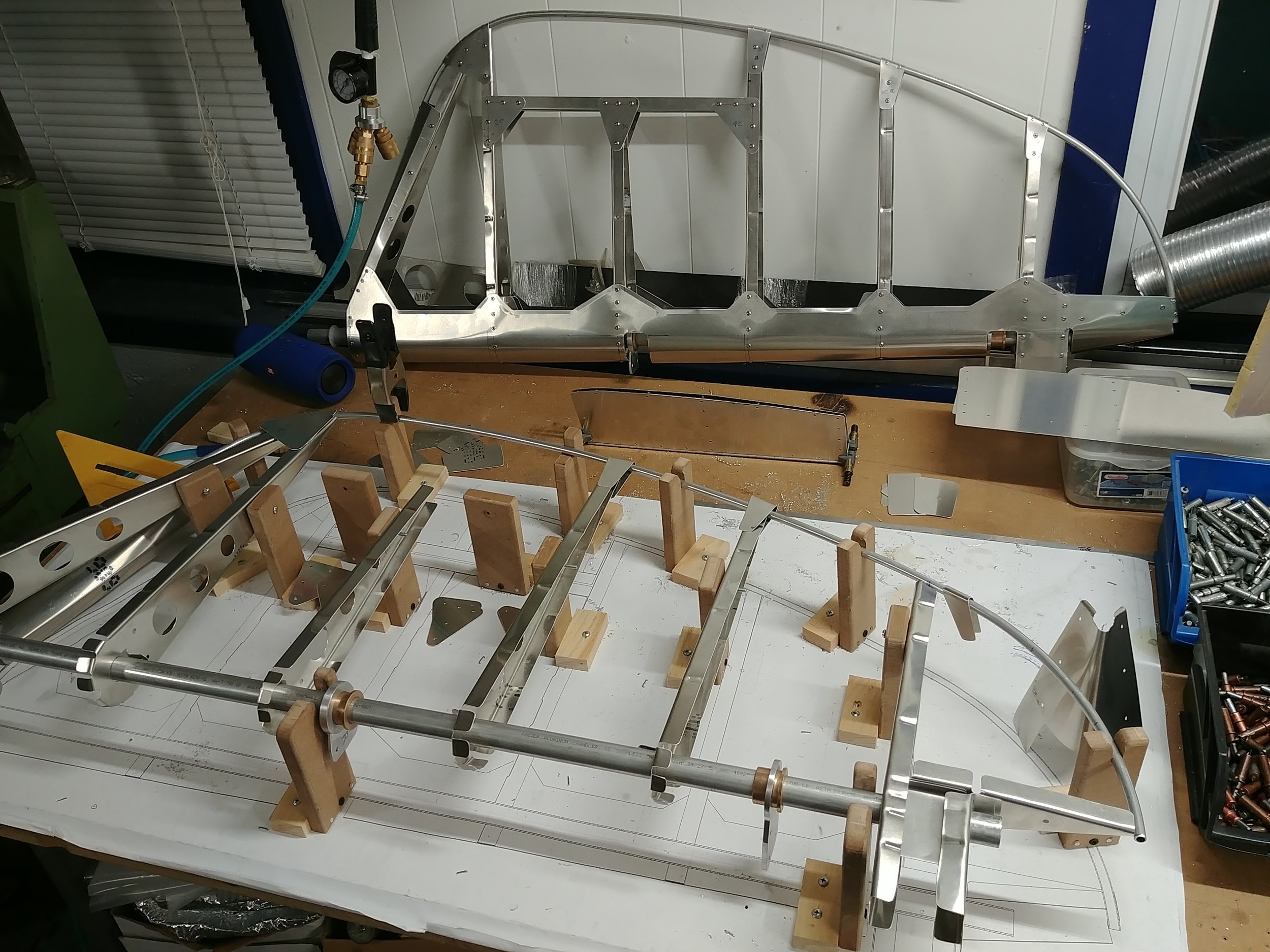

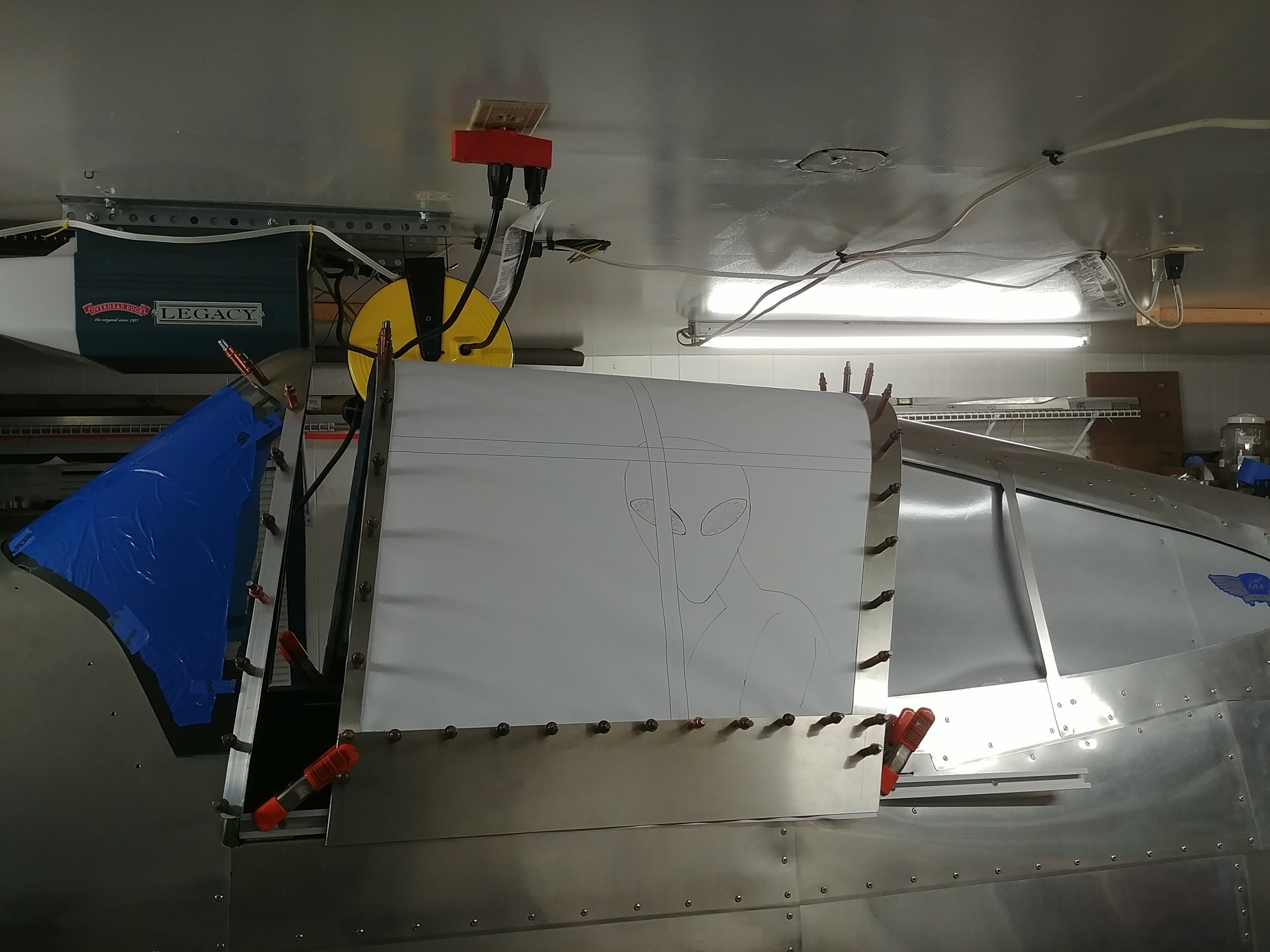

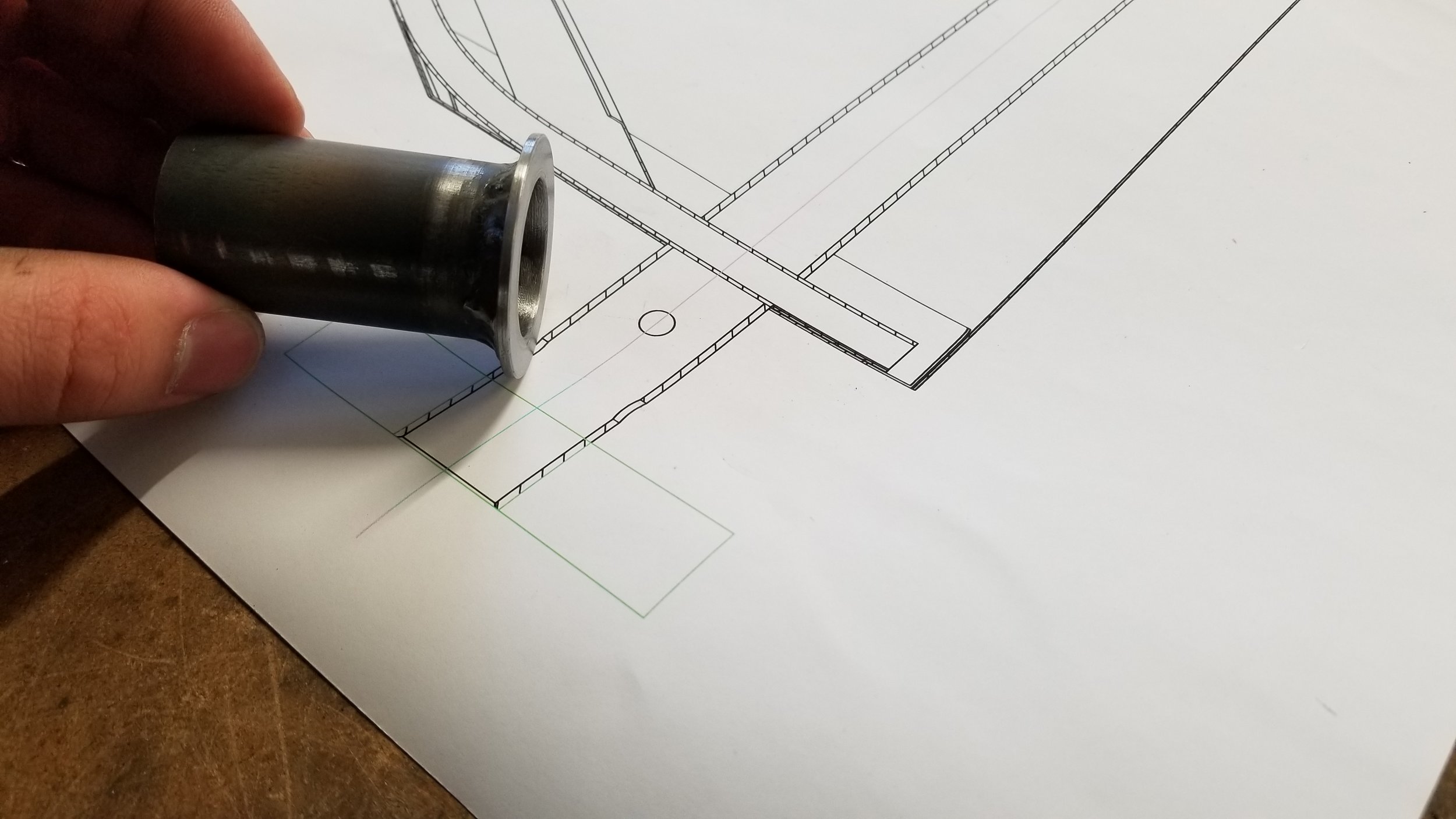

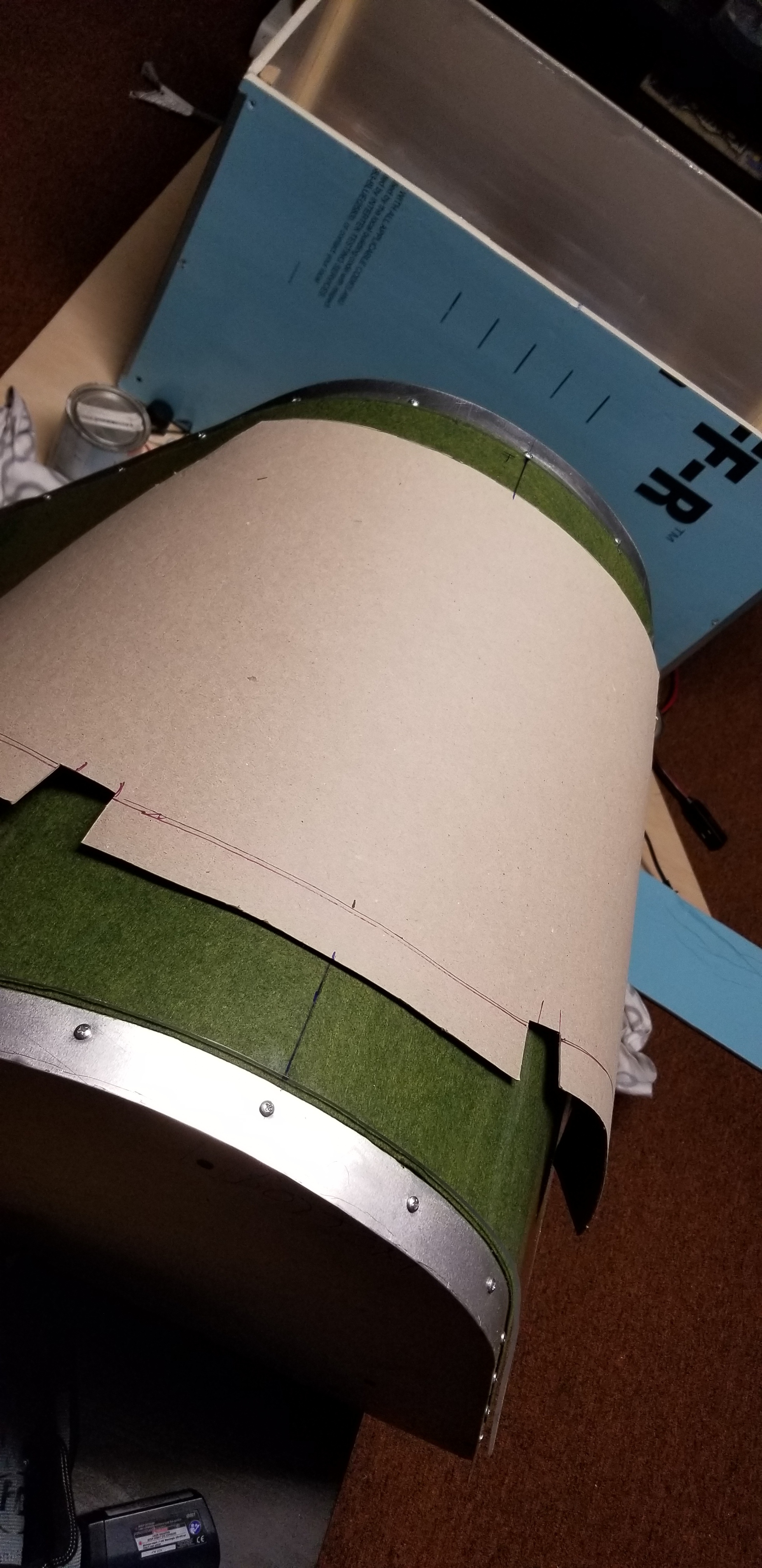

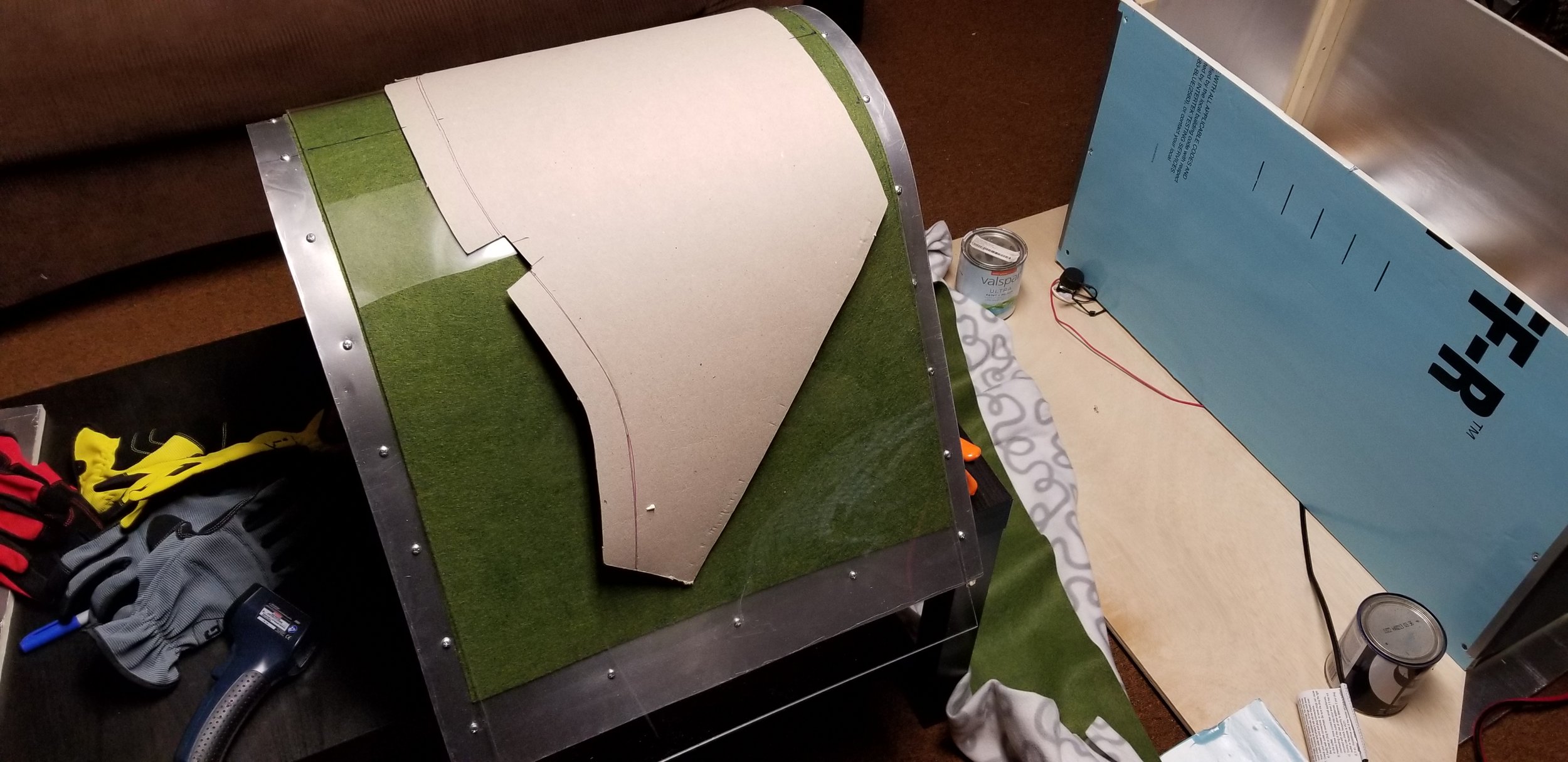

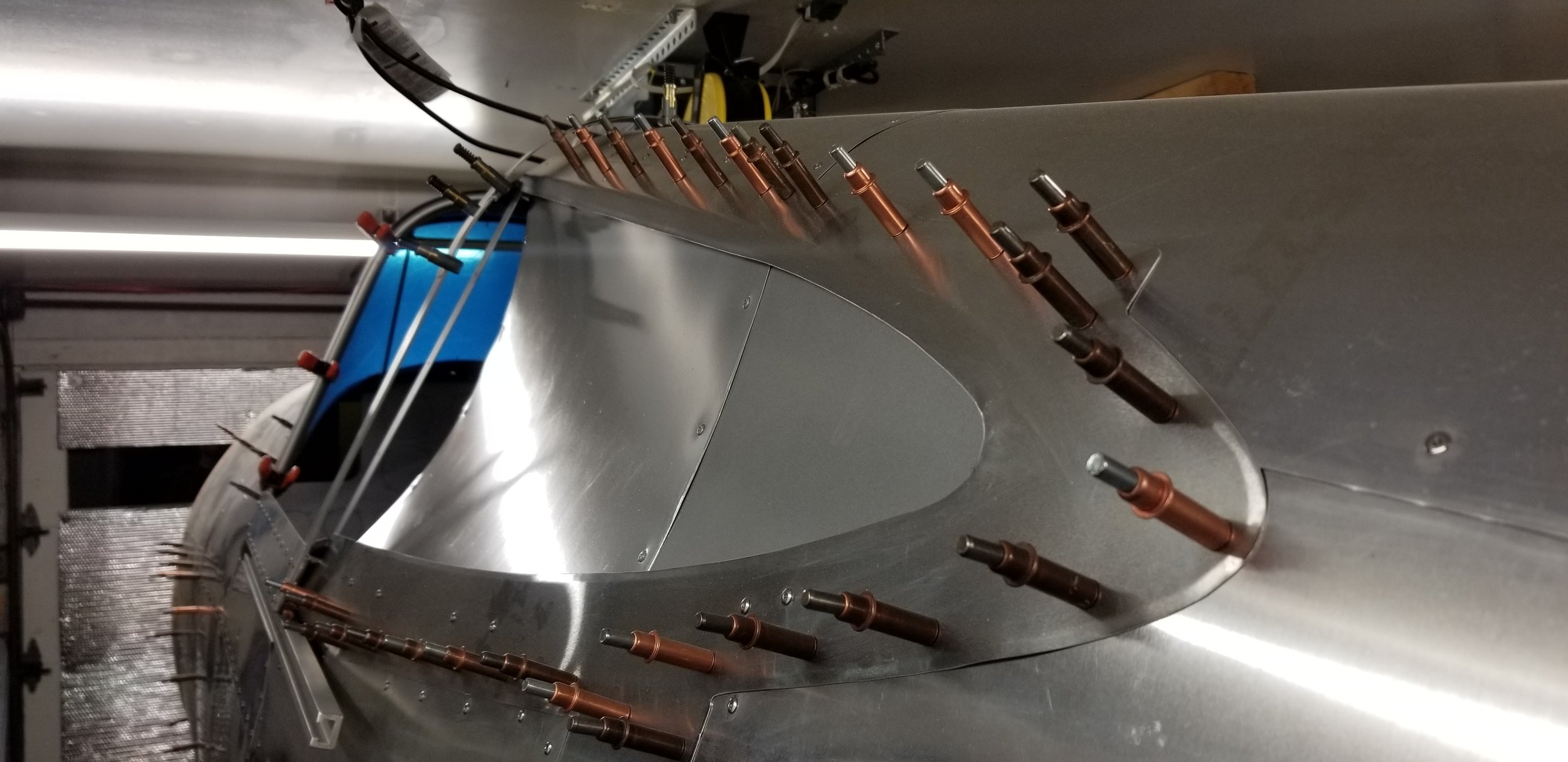

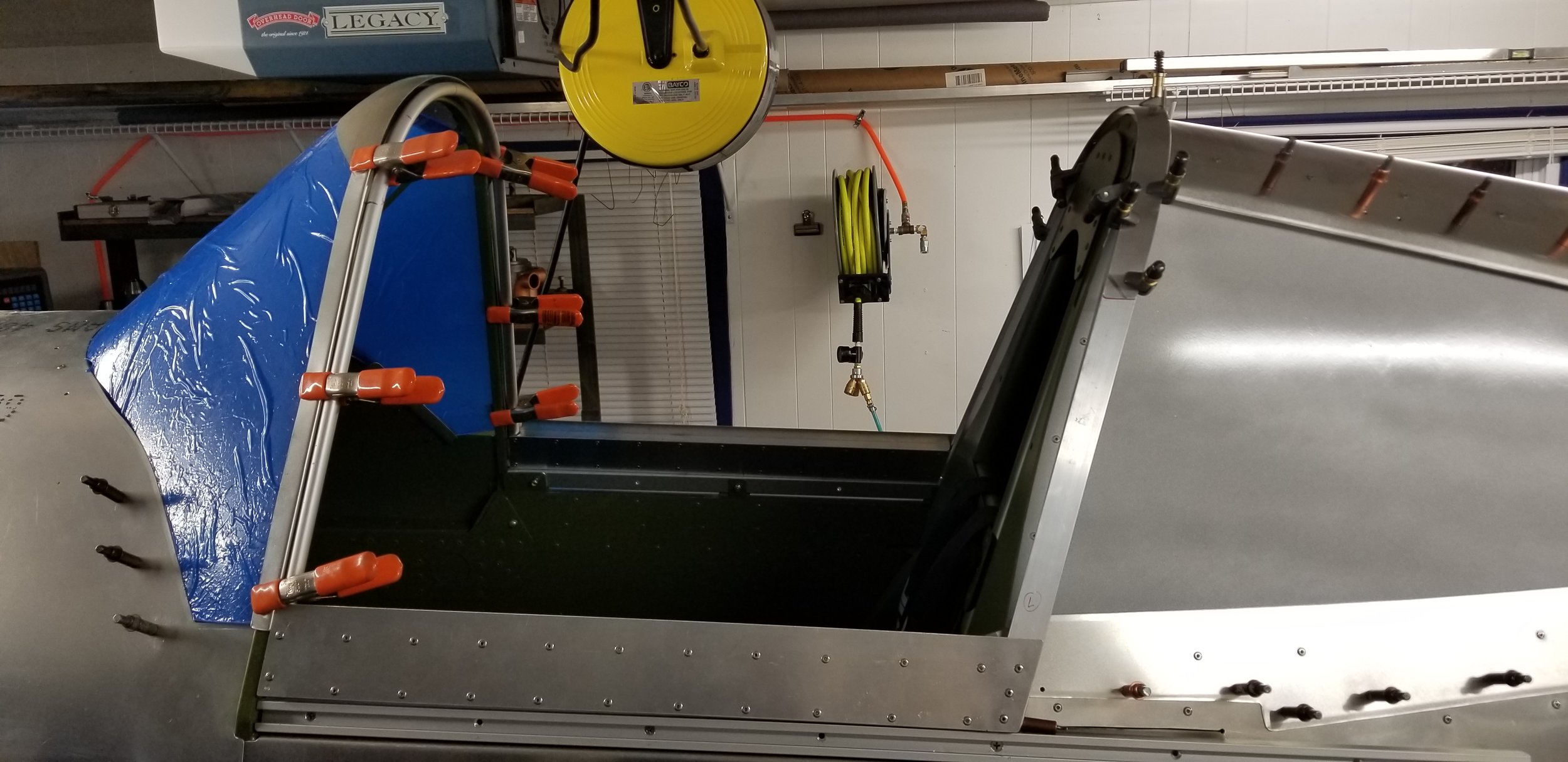

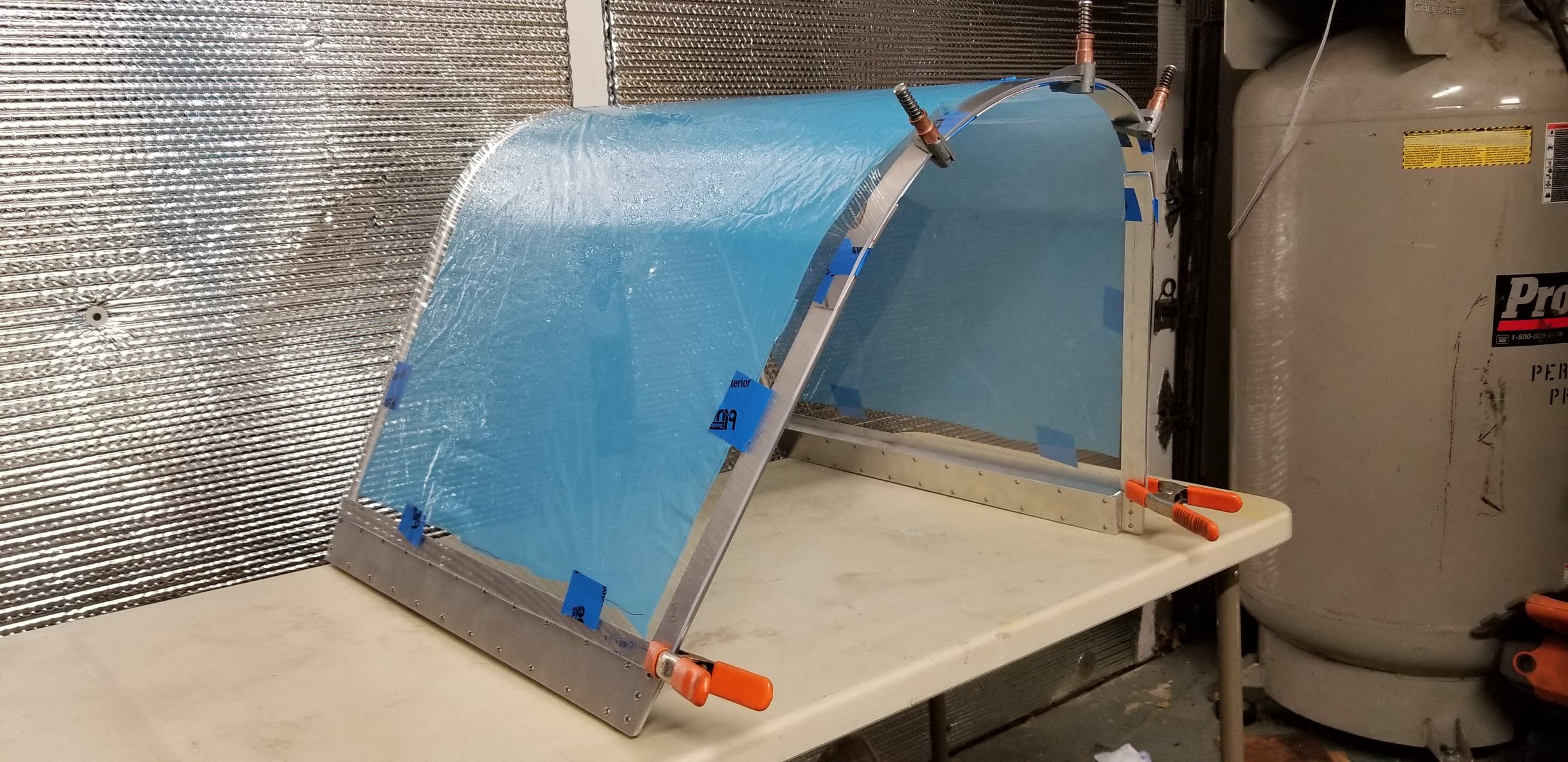

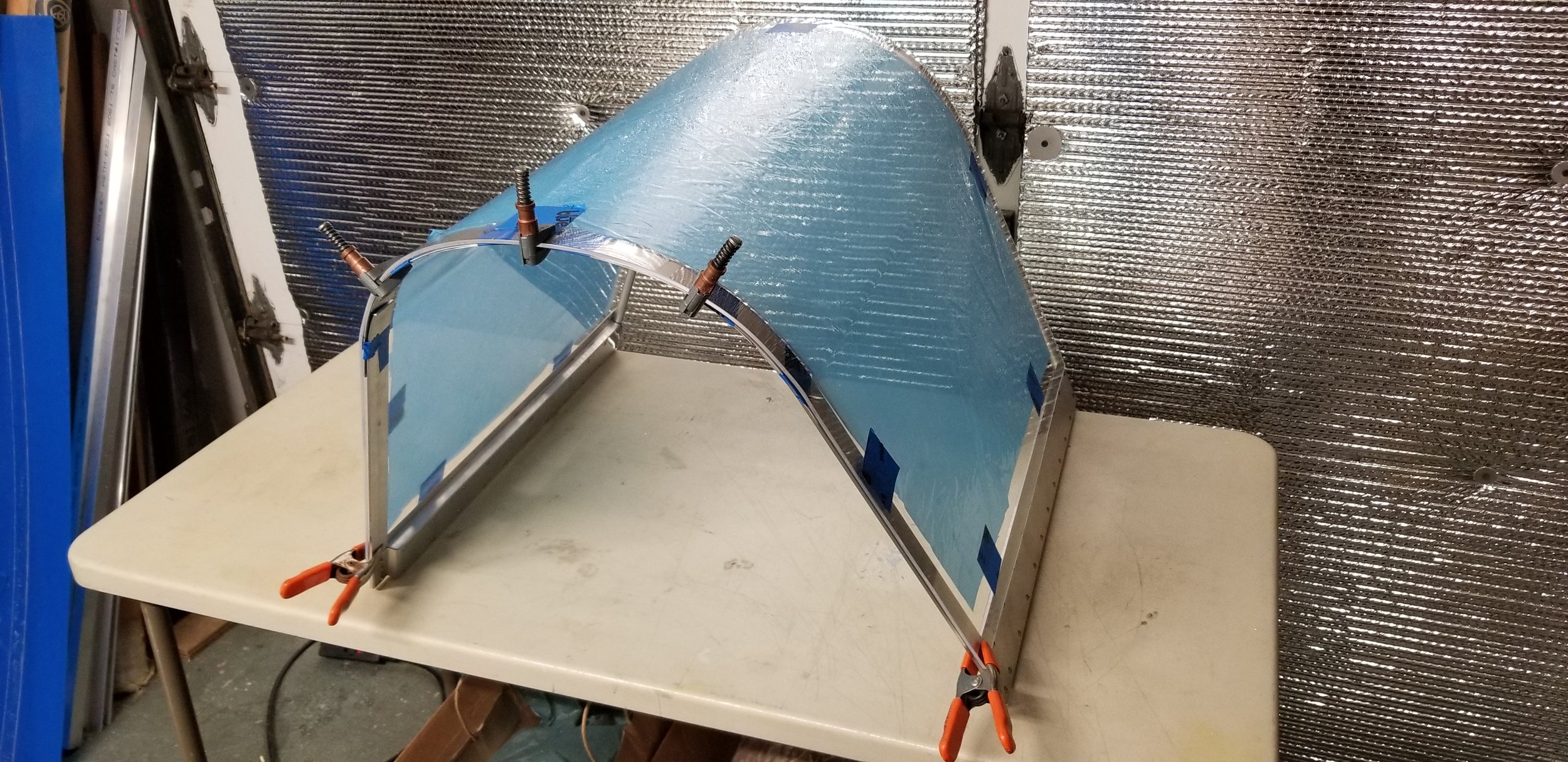

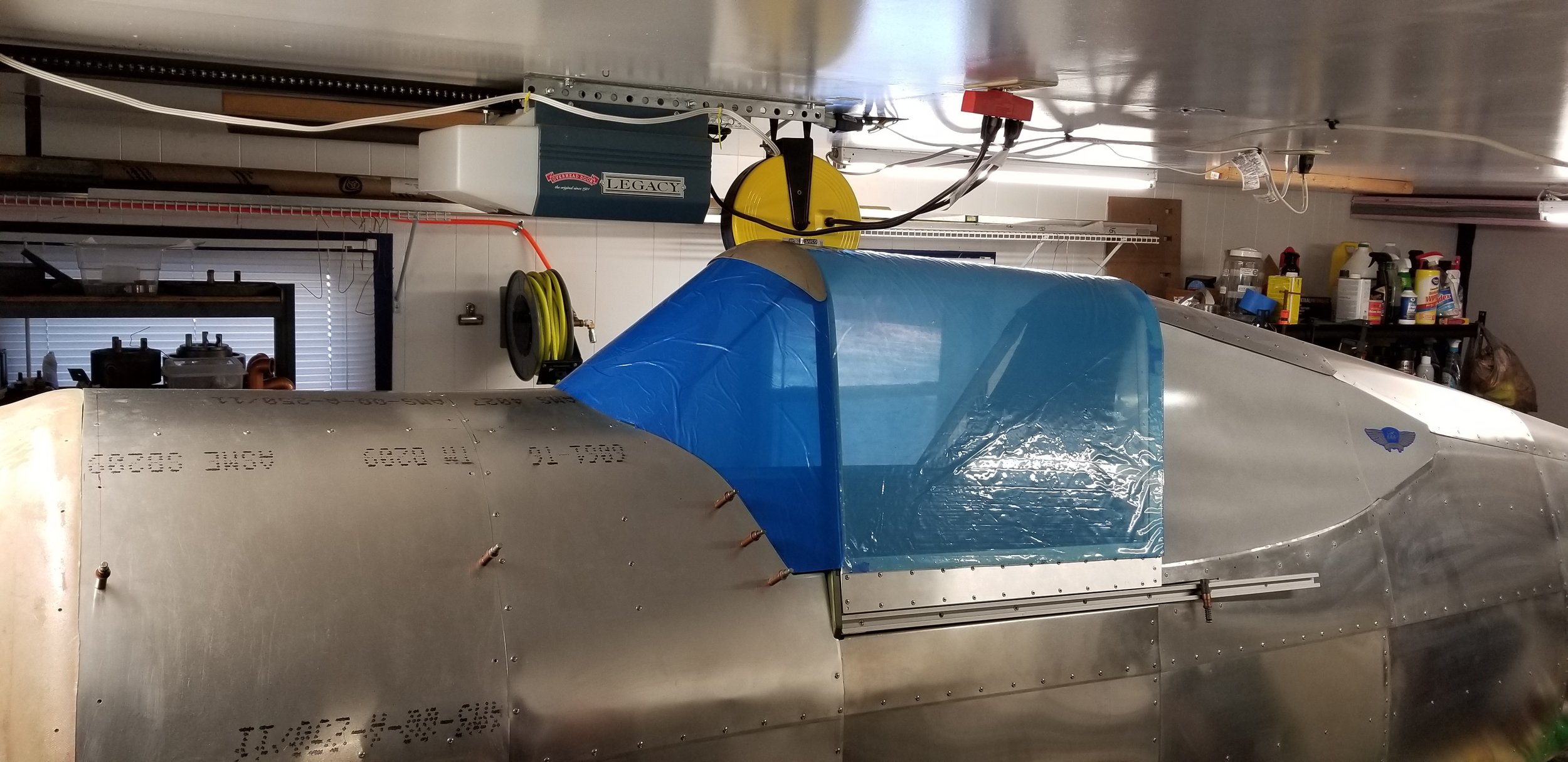

The engineering effort has been in full swing. Centered around the structural loading and design of the main spar, aft spar, ribs and mounting points for the center section of the wing and the outboard wing panels. Paul made a great report for us and has been cross checking every number. This just takes time. Paul has had to figure the material and thicknesses, rivet patterns, bolt patterns and sizing for all of it. So we have been patient and keeping busy with other parts of the project. Over the next few weeks, we will be adjusting the CAD models and getting ready to make wing parts. I will be finishing the last bit of work on the tail fairings effort.

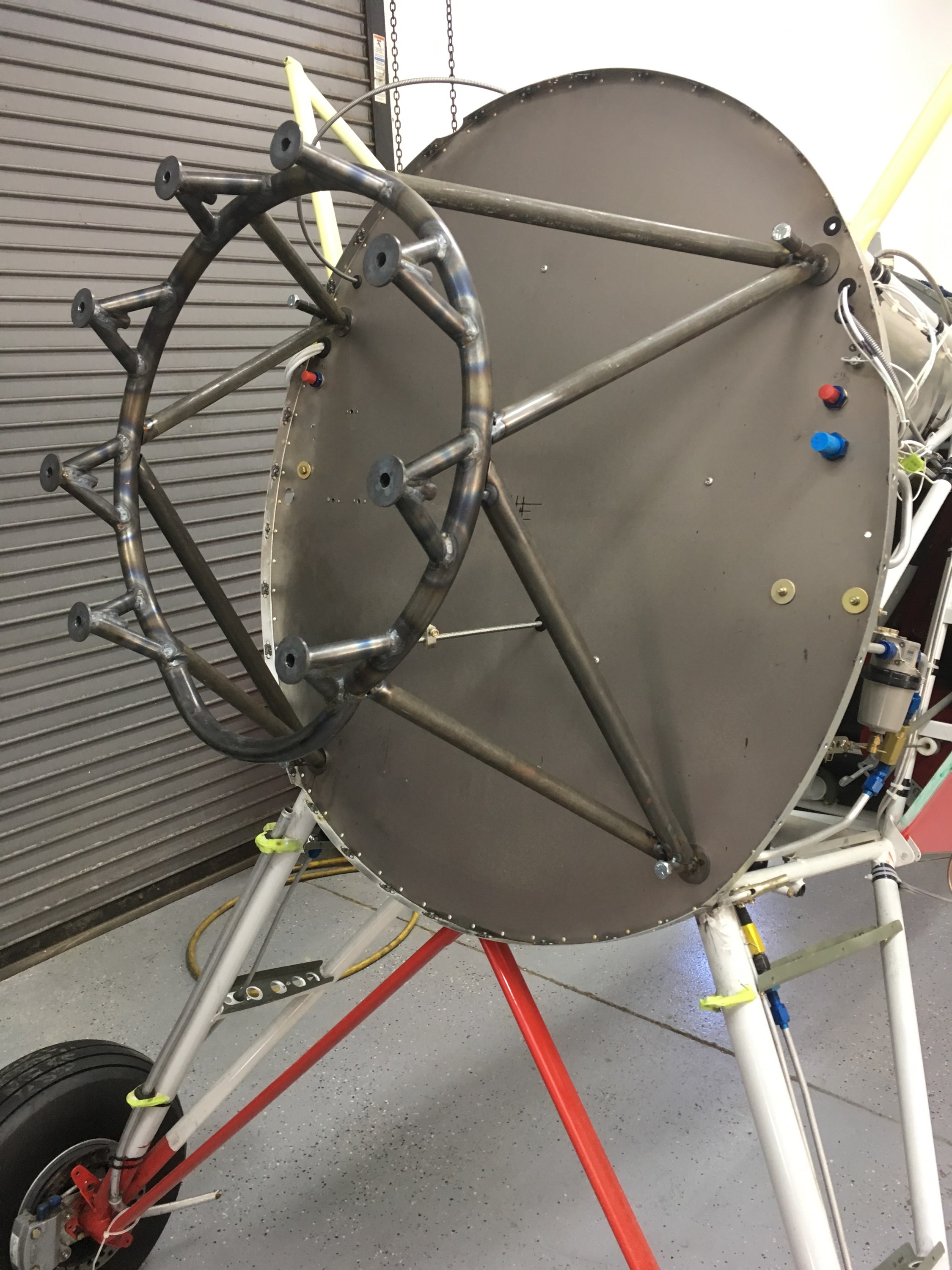

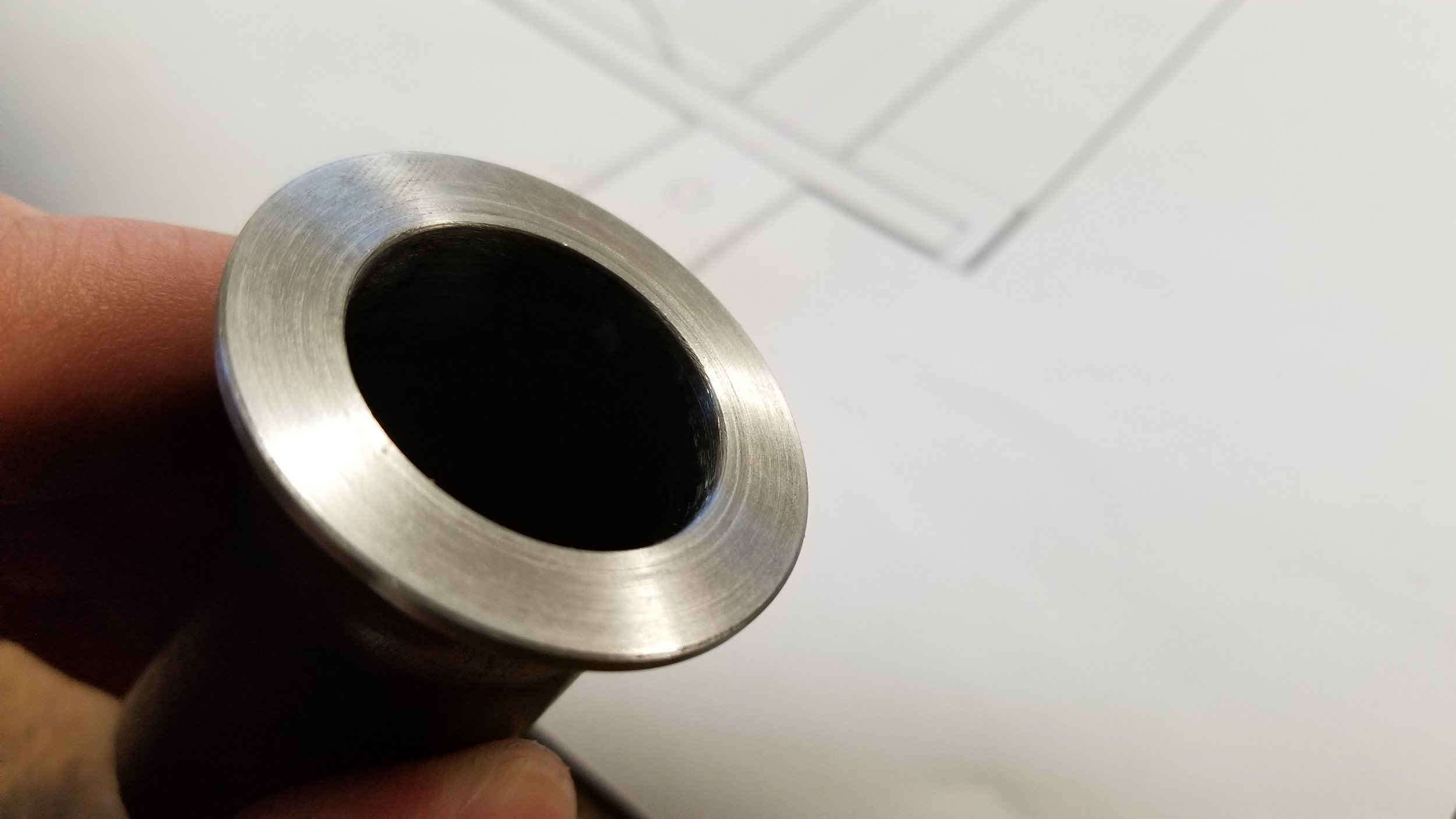

Design wise, Scott has been making progress on the prototypes’ fixed landing gear. Our approach is to make their mounting and components as much of the retract design as we can do. The down-links will likely be long fixed bars instead of articulating. Some of the swivel assembly will not be installed and the retraction/extension motor and brackets will not be installed yet. We will get it going with that and then after the flight testing is done and we have some time to work on it, we will modify the wing and gear to retract and swivel like real deal P-36. Then see how that affects the performance and make any adjustments as needed.

During late September, Scott and I went to Florida to visit one of our nine cylinder customers - Steve Wolf. We took a lot of video and still imagery of him and the Samson Mite biplane. We even bought the new GoPro Hero 7 camera and Steve made camera mounts. That arrangement worked perfectly on the wing strut for views of the fuselage. We have a couple of the easy to edit videos posted already on our YouTube channel (ScaleBirds). The harder ones to edit are going to take a bit longer. Mainly the air to air stuff. We had a lot of vibration and auto-focus adjustments that happened. Scott was riding in the second seat out in the open of an AirCam twin engine aircraft while Steve was flying formation and rolling off. The constant air blast was moving the camera a lot more than we figured. The engine and air noise was deafening too - so the audio is not likely to make the final video. We can dub in some good radial engine sounds or music. Or like some Hollywood movies, we could dub in some jet engine sound for added realism! Haha, or something crazy. We are trying to recover as much of the video imagery as we can with stabilization software. So we will be posting more videos and I promise you will like it!